Knurling press-in special-shaped terminal hole connector

A special-shaped terminal and connecting terminal technology, applied in the direction of connecting contact materials, contact parts, etc., can solve the problems of difficult assembly, terminal temperature rise, weak electrical performance, etc., to ensure the stability of electrical performance, improve assembly efficiency, and save money. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

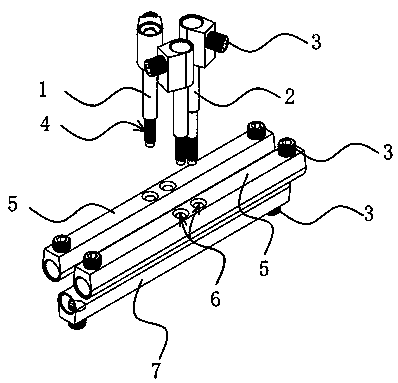

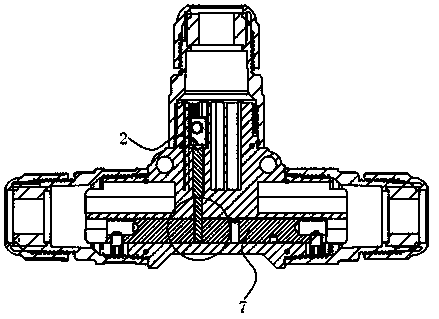

[0024] figure 1 , 3, 4 The integrated terminal includes a special-shaped terminal 5, upper terminals 1, 2, countersunk head screws 3 and rubber cores, the special-shaped terminal has a number of connection holes 6 that match the upper terminal, and the upper There is a knurled structure 4 at the front end of the terminal.

[0025] figure 1 As shown, the special-shaped terminal 5 is in a U shape as a whole, with wire insertion holes and threaded holes at both ends, and a terminal connection hole 6 in the middle, and the terminal connection hole 6 is symmetrical about the center.

[0026] figure 1 As shown, the tails of the upper terminals 1 and 2 are U-shaped, and the U-shape includes a wire insertion hole and a threaded hole. The middle part of the upper terminal is cylindrical and connected to the knurled structure. The knurl structure is provided with a...

Embodiment 2

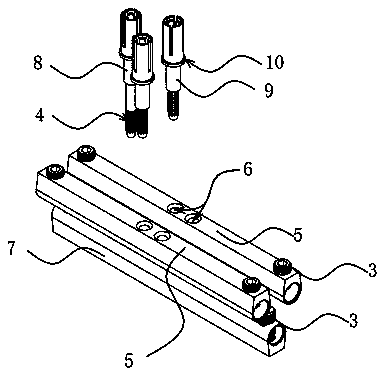

[0029] figure 2 , as shown in 5 and 6, the plug-in terminal structure, in this embodiment, its structure is basically similar to that of Embodiment 1, the difference is that: the upper terminal 2 is changed to a female terminal and a male terminal, and the matching male and female terminals are installed The rubber cores are the female end and the male end of the connector respectively. The female terminal and the male terminal are provided with a terminal force-receiving round table 10, which is used to limit the over-insertion of the terminal and prevent the deformation of the male / female terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com