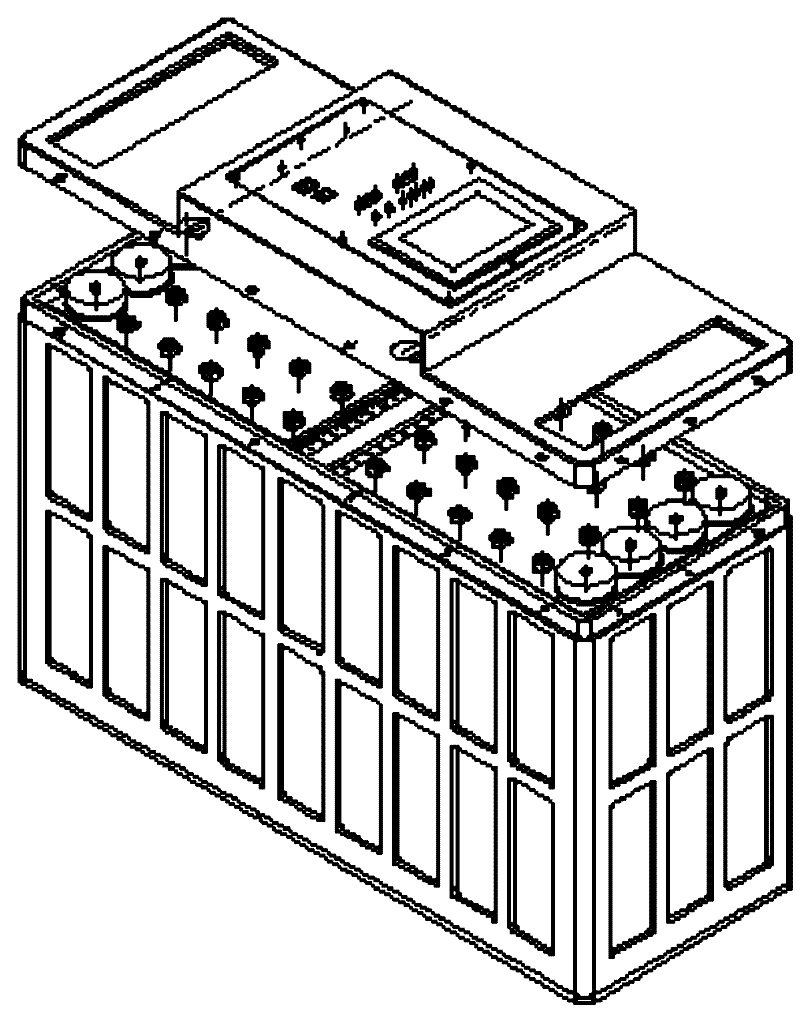

High-capacity lithium ion battery module

A technology for lithium-ion batteries and battery modules, which is applied in battery pack components, non-aqueous electrolyte batteries, and electrolyte battery manufacturing, etc., can solve problems such as many connection points, poor dynamic balance of battery cells, and large number of battery cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

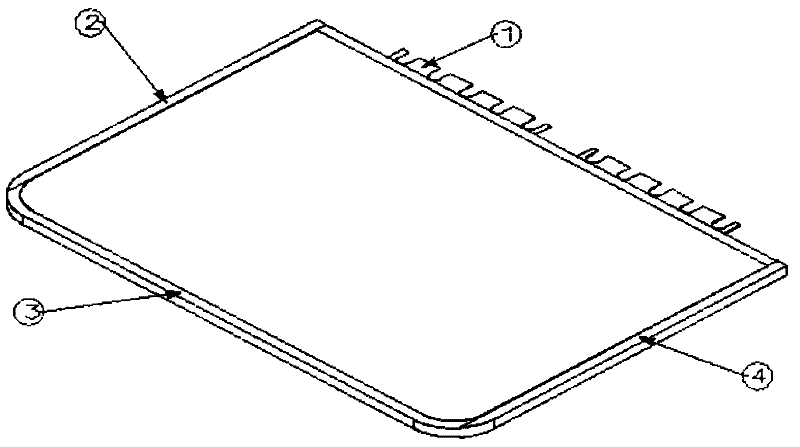

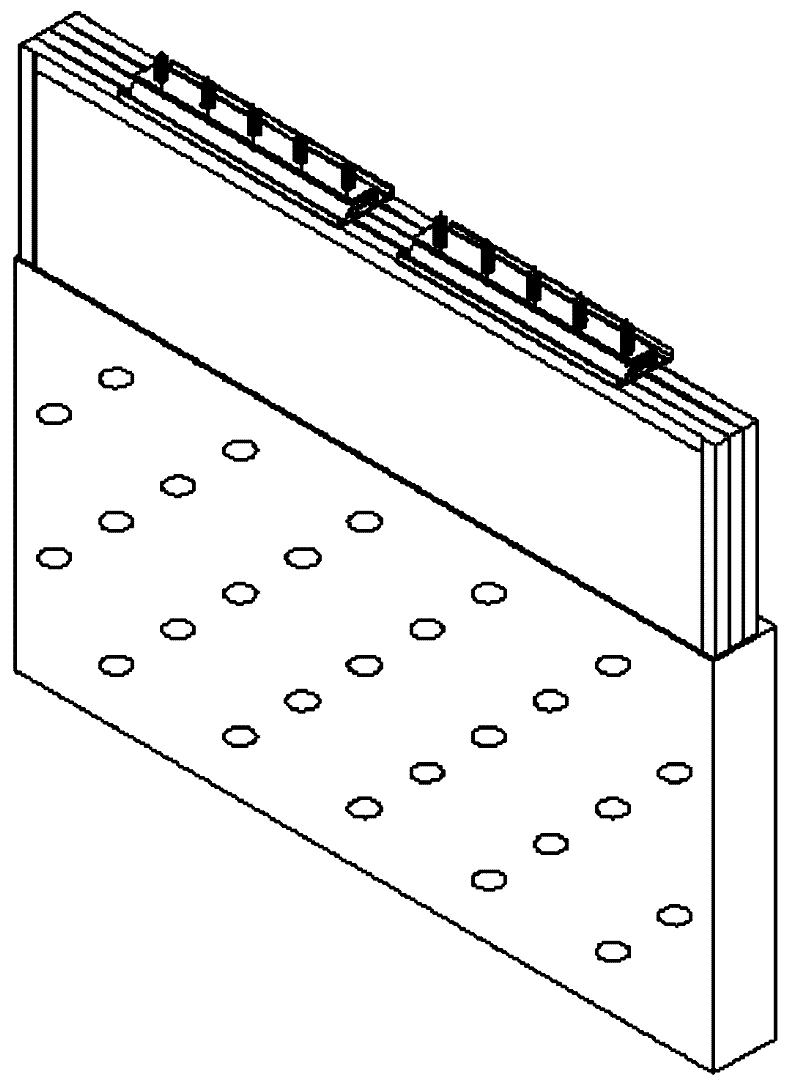

[0026] The 500Ah battery cell produced by our company is used, and the frame is packaged with epoxy resin material. After the curing is complete, the battery cell tabs are punched out of 5 U-shaped grooves, such as figure 2 shown. Among them, the thickness of packaging frames 1 and 3 is the same as the thickness of the battery cell, and the thickness of 2 and 4 exceeds the thickness of the battery by 3mm, and the thickness of the single side exceeds the thickness of the battery by 1.5mm. A battery unit is composed of four 500Ah battery cells, and the battery cells are placed in the case of the battery unit in the order that the positive pole corresponds to the positive pole and the negative pole corresponds to the negative pole, as shown in image 3 shown. The thickness of the shell of the battery unit is 2mm, and there are through holes on the bottom and the two surfaces parallel to the battery pole piece to ensure the heat dissipation of the battery. At the same time, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com