Variable-temperature test system and test method for VOC (volatile organic compound) diffusion performance of automobile parts

A technology of auto parts and testing system, which is applied in the field of chemical testing, can solve the problems of reducing volatile organic compounds of automotive interior materials, unable to understand the relationship between the emission performance of parts and temperature, and shorten the test time and the relationship between temperature and temperature Reasonable, avoiding the effects of differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

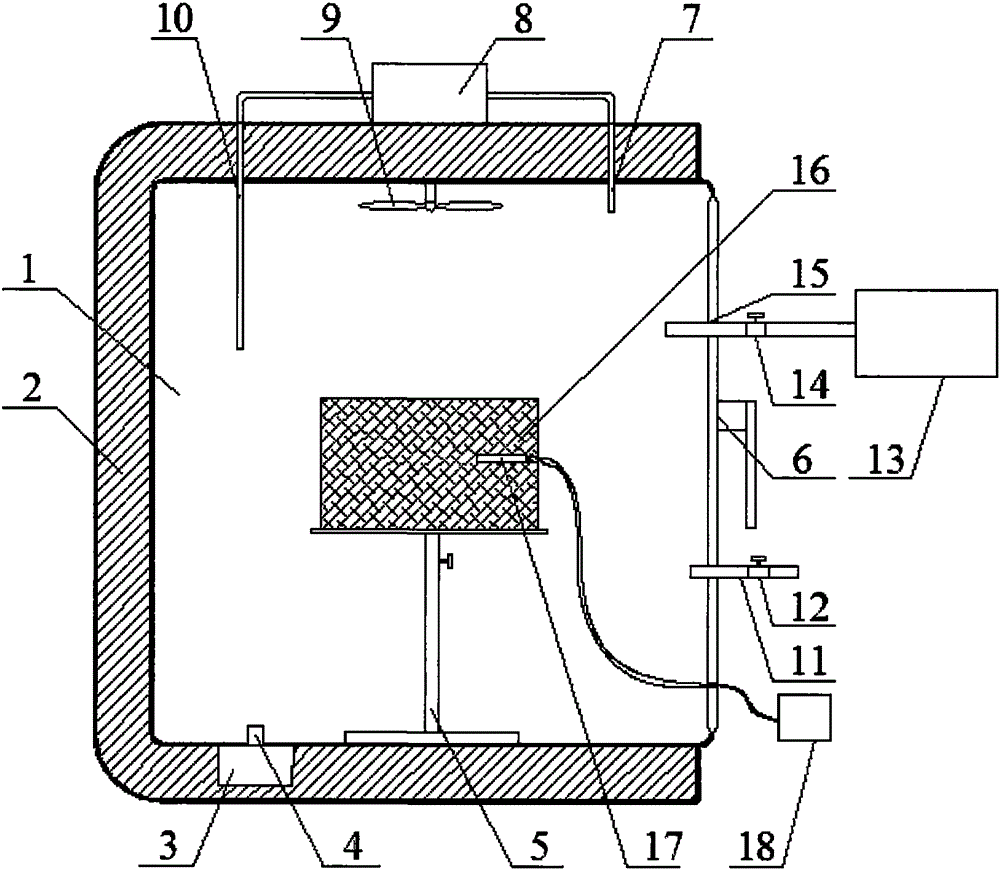

[0022] The working principle and specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The specific steps are:

[0024] Step 1: One day before the test, the experimenters need to wipe the bulkhead of the stainless steel environmental chamber 1 once with methanol, and then wipe it twice with deionized water. After wiping, heat the environmental chamber 1 at 100 degrees for at least 12 hours to remove the residue in the chamber VOC impact.

[0025] Step 2: Adjust the test conditions of the environmental chamber 1 2 hours before the test, and keep the environmental chamber 1 at the first test temperature point of 20±1 degrees, 50±5%, and the maximum ventilation state.

[0026] Step 3: Collect the gas in the environmental chamber 1 one hour before the test, and test the background concentration of the environmental chamber 1. It is required that the TVOC in the background concentration is less than 50 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com