Preparation method for 2-propyl enanthol

A technology of propyl heptanol and catalyst, which is applied in the field of preparation of higher aliphatic alcohols, and can solve the problems of unreached, unsatisfactory high efficiency, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

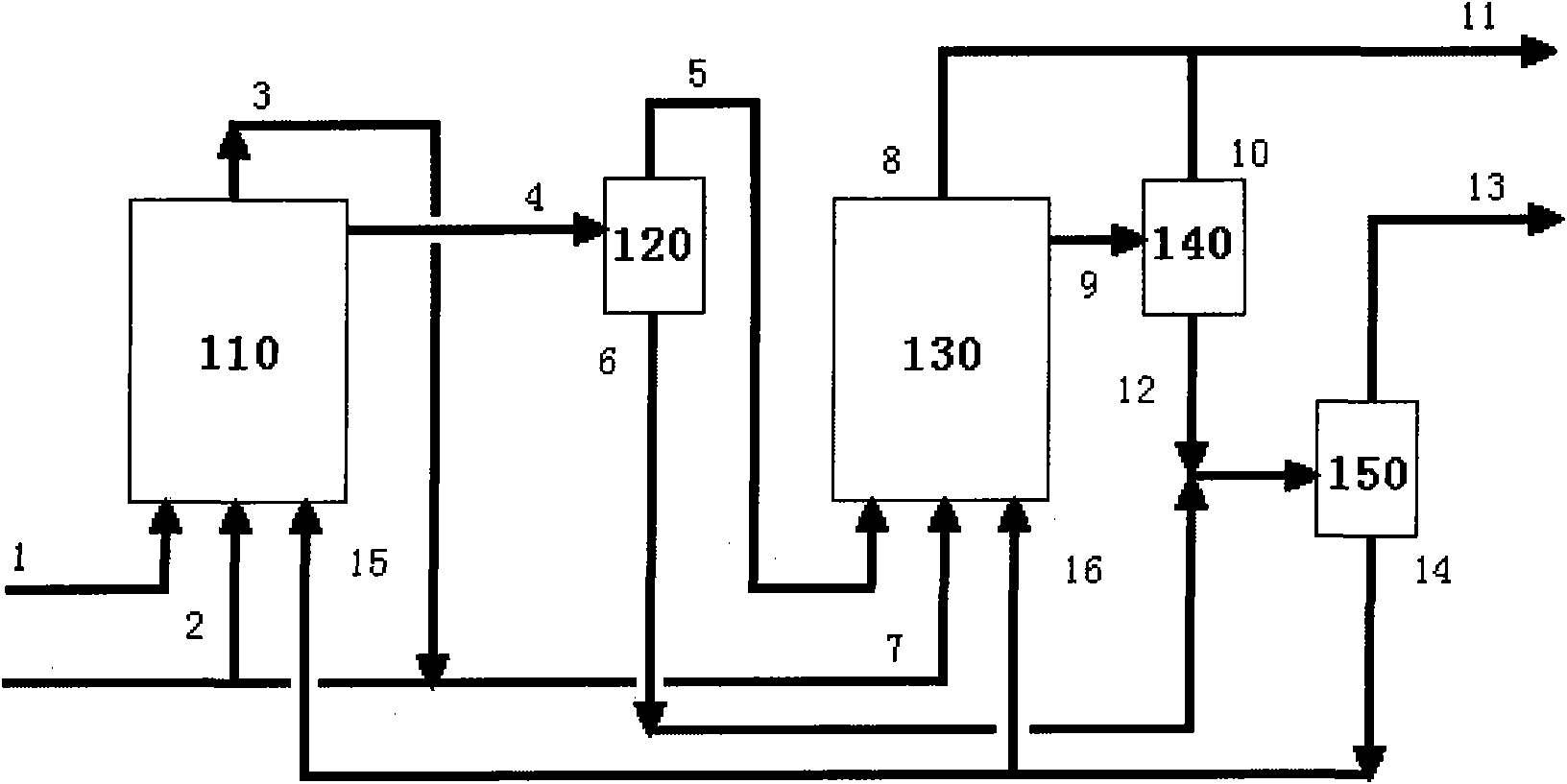

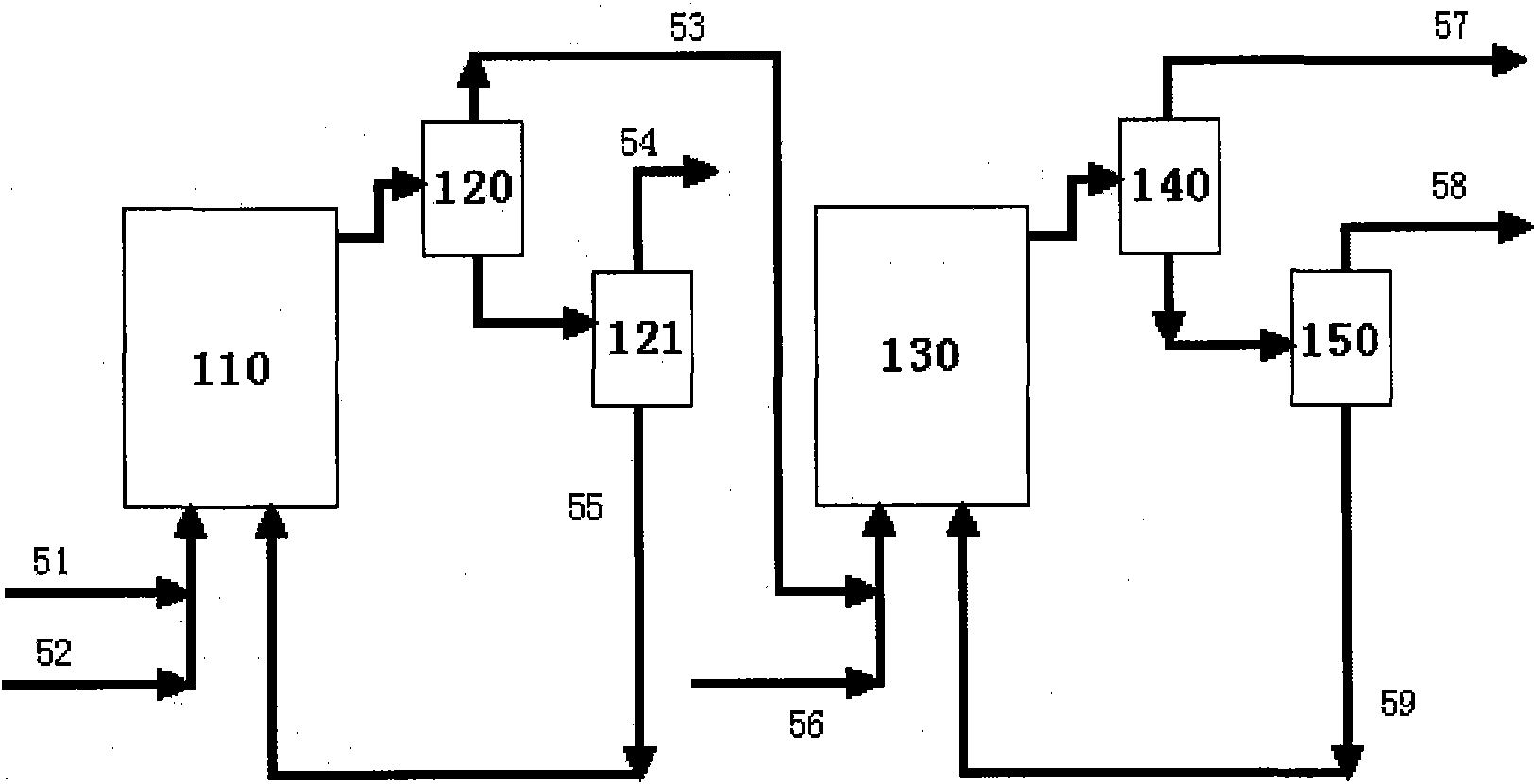

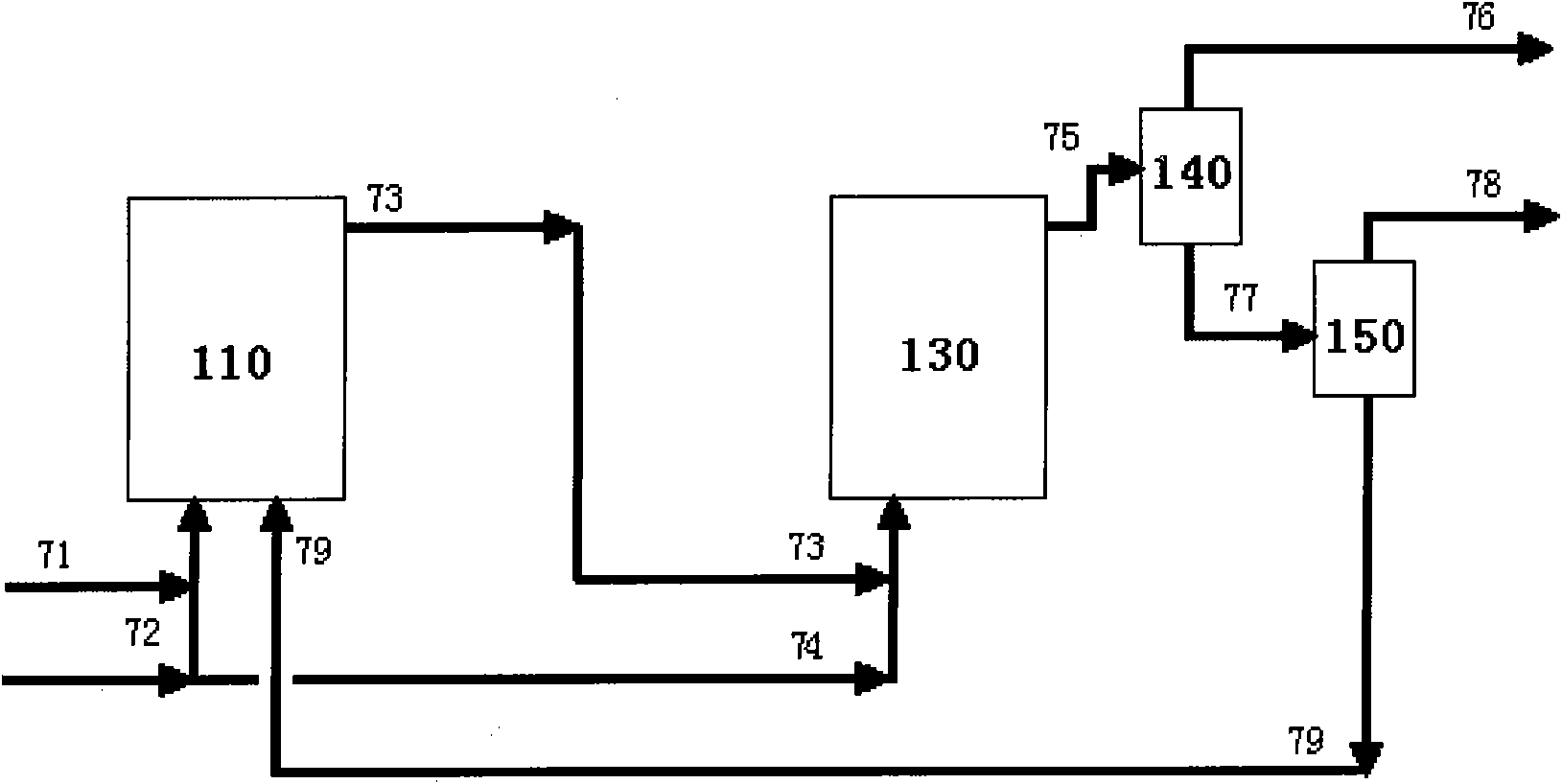

Method used

Image

Examples

Embodiment 1

[0081] In this example, a phosphite with the following structure is used as the catalyst ligand:

[0082]

[0083] Among the mixed butene raw materials used in hydroformylation, by mass ratio, 1-butene accounts for 62.7%, trans-2-butene accounts for 13.9%, cis-2-butene accounts for 9.0%, butane accounts for 12.9%, Isobutene content <1%.

[0084] The first hydroformylation reaction is carried out in a pressure vessel with a magnetically coupled stirring device. The device also has heating and temperature control parts, pressure display and control parts, and quantitative feeding parts of butene. The autoclave is connected to cylinders filled with synthesis gas and nitrogen. The test uses rhodium dicarbonyl acetylacetonate as a catalyst and toluene as a solvent. The specific operation steps are: preparing catalyst solution according to a certain concentration, adding it into a pressure vessel under the protection of nitrogen, and replacing it with nitrogen for 7 to 8 times...

Embodiment 2

[0096] Embodiment 2, two-stage hydroformylation reaction:

[0097] Adopt the method described in embodiment 1 to test, difference is that the mass concentration of catalyst rhodium is 400ppm, the first step allows reaction to be carried out at 55 ℃ for 1.5 hours, then the second step reaction is carried out at 85 ℃ for 1.5 hours, other Conditions remain the same. The result of the reaction is:

[0098] Table 4 hydroformylation reaction results

[0099] Olefin Conversion

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com