Novel four-laminated non-crystallite germanium-silicon thin film solar battery and preparation method thereof

A solar cell and non-microcrystalline technology, which is applied in the field of solar cells, can solve problems such as influence and need to be further improved after technological innovation, and achieve the effects of simple preparation equipment, improved photoelectric conversion efficiency, and stable battery structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

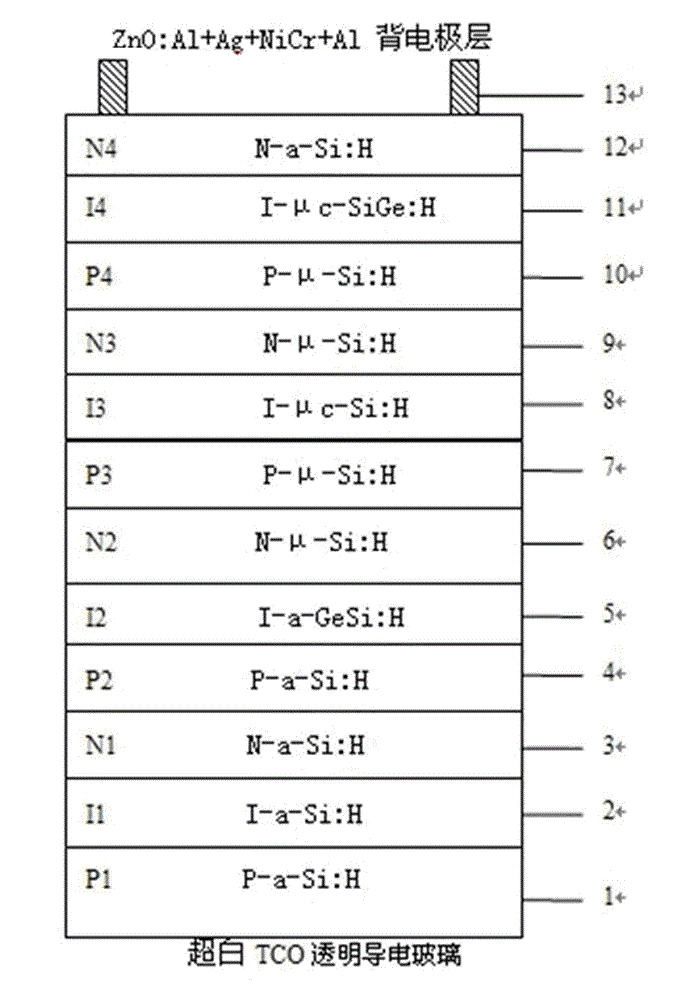

[0011] The novel four-stack amorphous germanium-silicon thin-film solar cell of the present invention is provided with four-junction stacked sub-cells in series; the first junction is a PIN structure composed of P1 layer, I1 layer, and N1 layer, and the second junction is a P2 layer , I2 layer, N2 layer composed of PIN structure, the third junction is PIN structure composed of P3 layer, I3 layer, N3 layer, the fourth junction is PIN structure composed of P4 layer, I4 layer, N4 layer, wherein P1 layer, P2 layer The layer is made of P-type a-Si material, the P3 and P4 layers are made of P-type μc-Si material, the N1 and N4 layers are made of N-type a-Si material, and the N2 and N3 layers are made of N-type μc-Si material. The I1 layer is made of a-Si material, the I2 layer is made of a-SiGe material, the I3 layer is made of μc-Si material, and the I4 layer is made of μc-SiGe material. On the white float glass substrate, a ZnO:Al layer is provided on the fourth junction, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com