Stirring paddle for reaction kettle

A stirring paddle and reaction kettle technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the impact of reflected progress, product production efficiency, inability to meet market demand, motor power Large and other problems, to achieve the effect of reducing power requirements, reducing weight, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

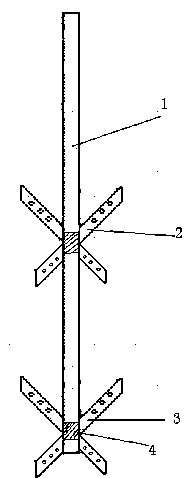

[0010] In order to further understand the stirring paddle with rotating blades, the description is as follows in conjunction with the diagram:

[0011] It includes: a stirring shaft 1 and a blade group 2, the blade group 2 is composed of two intersecting blades, the angle between the two blades is 30-60 degrees, the blade body is provided with a through hole 3, The diameter of the through hole 3 is 10~20mm, and the distance between the through holes 3 is the same. It is characterized in that: a bearing 4 is provided between the blade group 2 and the stirring shaft 1, and a sealing sleeve is provided outside the bearing 4; the blade group 2 is controlled by Motor control; the blade group 2 rotates with the stirring shaft 1 as the central axis.

[0012] The blade groups 2 have a double-row structure, and the distance between two rows of blade groups 2 is 30-50 cm.

[0013] The blades are made of high-precision ceramic materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com