Roller of aluminum tube rolling mill

A rolling mill and roll technology, applied in the field of aluminum tube processing equipment, can solve the problems of short life and breakage of the roll, and achieve the effects of improving production efficiency, good bearing capacity and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

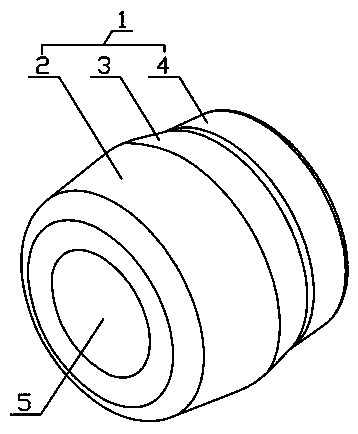

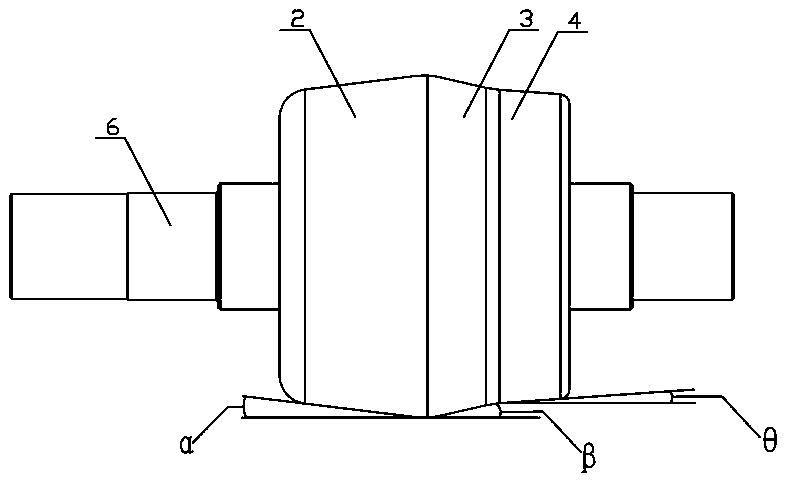

[0014] In this embodiment, a roll of an aluminum tube rolling mill has a roll body 1, and the roll body 1 is divided into a feed side and a discharge side along the roll peak, one left and one right, and the feed side is a diameter gradually along the feed direction. Increased circular cone A2, the feed angle α formed by the conical surface of the circular cone A2 in the horizontal direction is 6°, and the discharge side is successively composed of a circular shape whose diameter gradually decreases along the discharge direction. The cone B3 and the circular cone C4 are formed, and the discharge angle β and the discharge angle θ formed by the conical surfaces of the circular cone B3 and the circular cone C4 in the horizontal direction are 13° and 4° respectively.

[0015] In this embodiment, the roller body 1 is provided with a central through hole 5, and the roller shaft 6 is interference-fitted in the central through hole 5, and the center line of the roller body 1 and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com