Large water-cooling die for thermal forming of high-strength steel plate

A high-strength steel plate, hot forming technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of difficulty in cooling quenching liquid, and achieve the effect of easy cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing and embodiment:

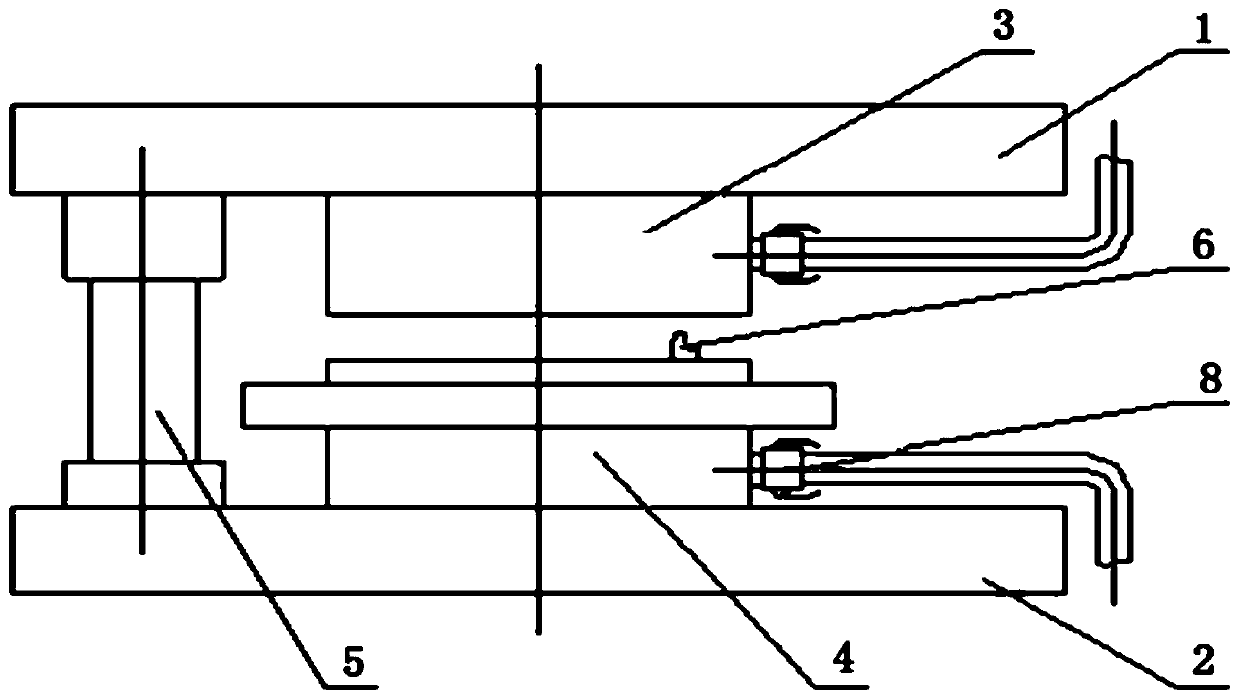

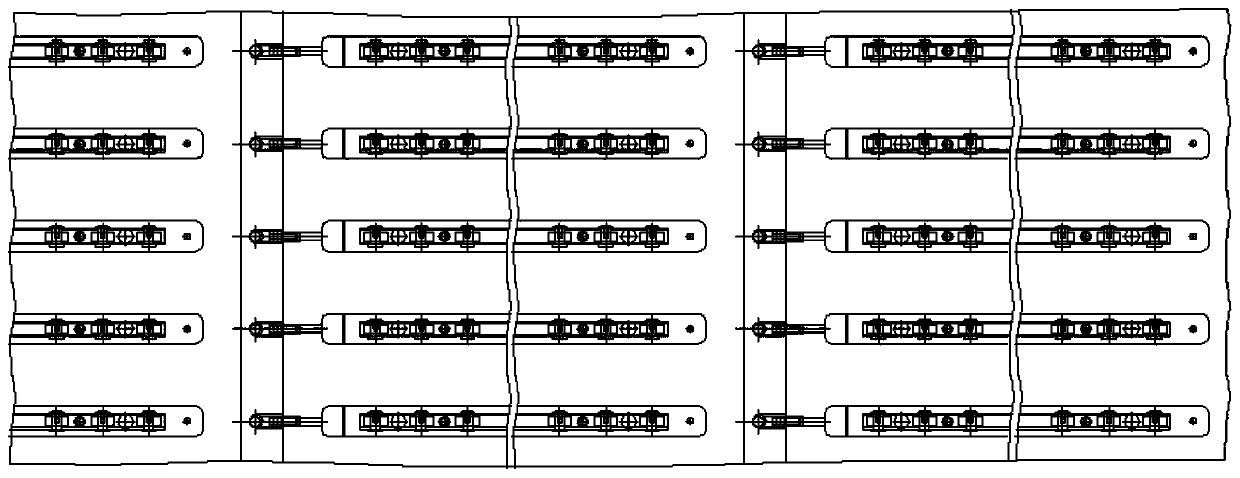

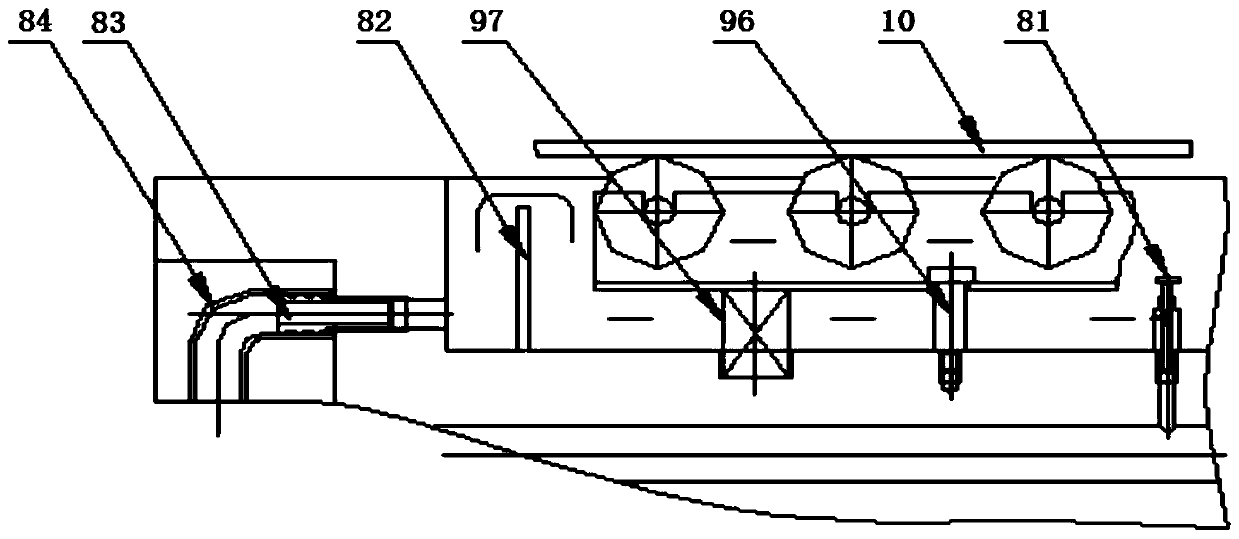

[0017] Such as figure 1 As shown, a large-scale water-cooled mold for hot forming of high-strength steel plates includes an upper mold frame 1, a lower mold frame 2, an upper mold insert 3, a lower mold insert 4, a guide device 5, a limit block 6, and a water cooling device 8 and slideway type feeding and discharging device 9. The upper mold insert 3 is installed on the upper mold frame 1, the lower mold insert 4 is installed on the lower mold frame 2; the guide device 5 is installed between the upper and lower mold frames and is located on both sides in front of the lower and lower mold inserts, guiding The device 5 is used to guide the sheet material 10 conveyed into the large water-cooled mold; the slideway type feeding and discharging device 9 is installed in the slideway installation groove of the lower mold insert 4, and is used to assist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com