Follower cooling structure for bilateral mechanical arm

A cooling structure and mechanical arm technology, applied in heating/cooling equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of untimely cooling, poor effect, and reduced mold life, etc., to achieve convenient cooling and structure Ingenious design and stable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

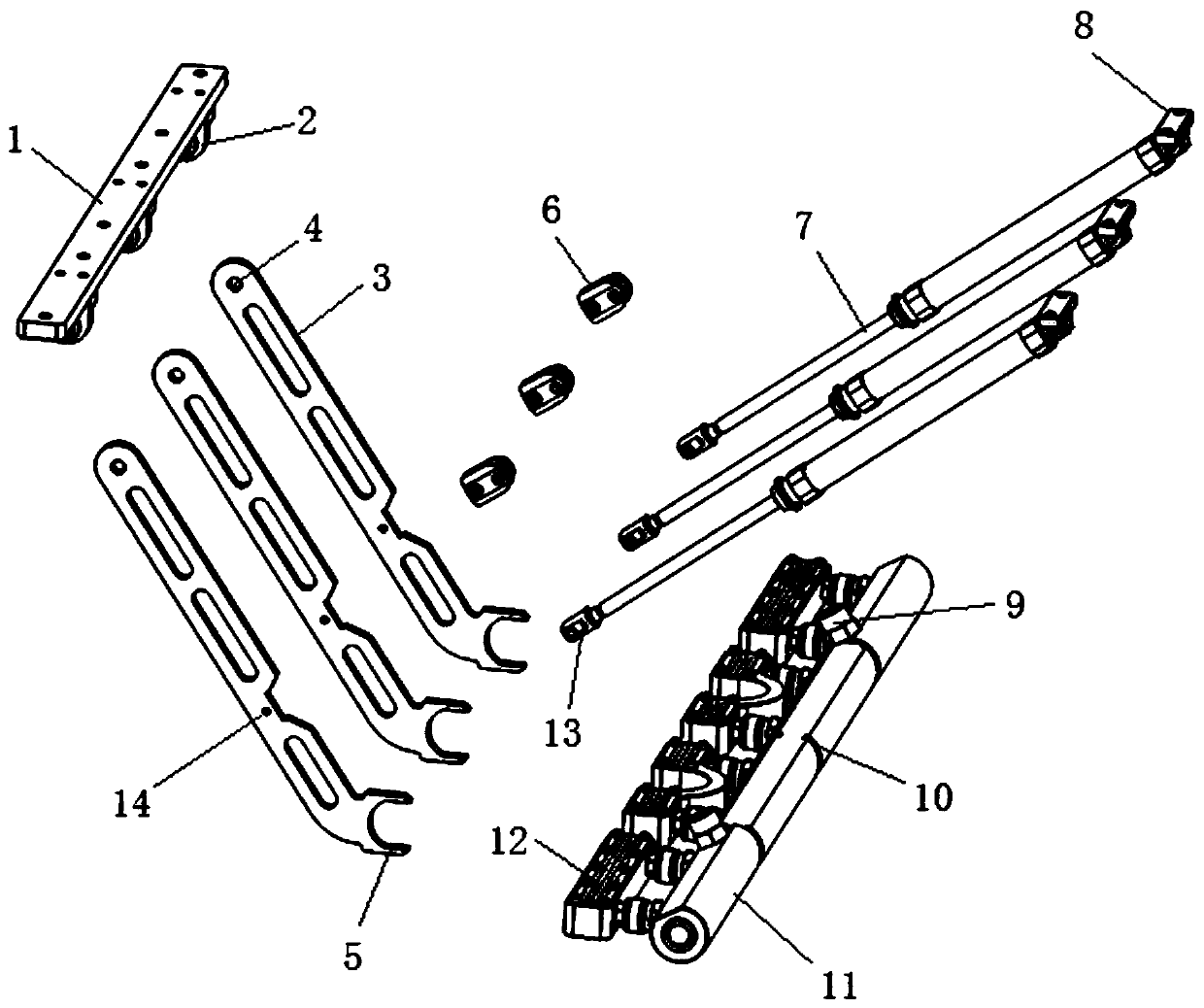

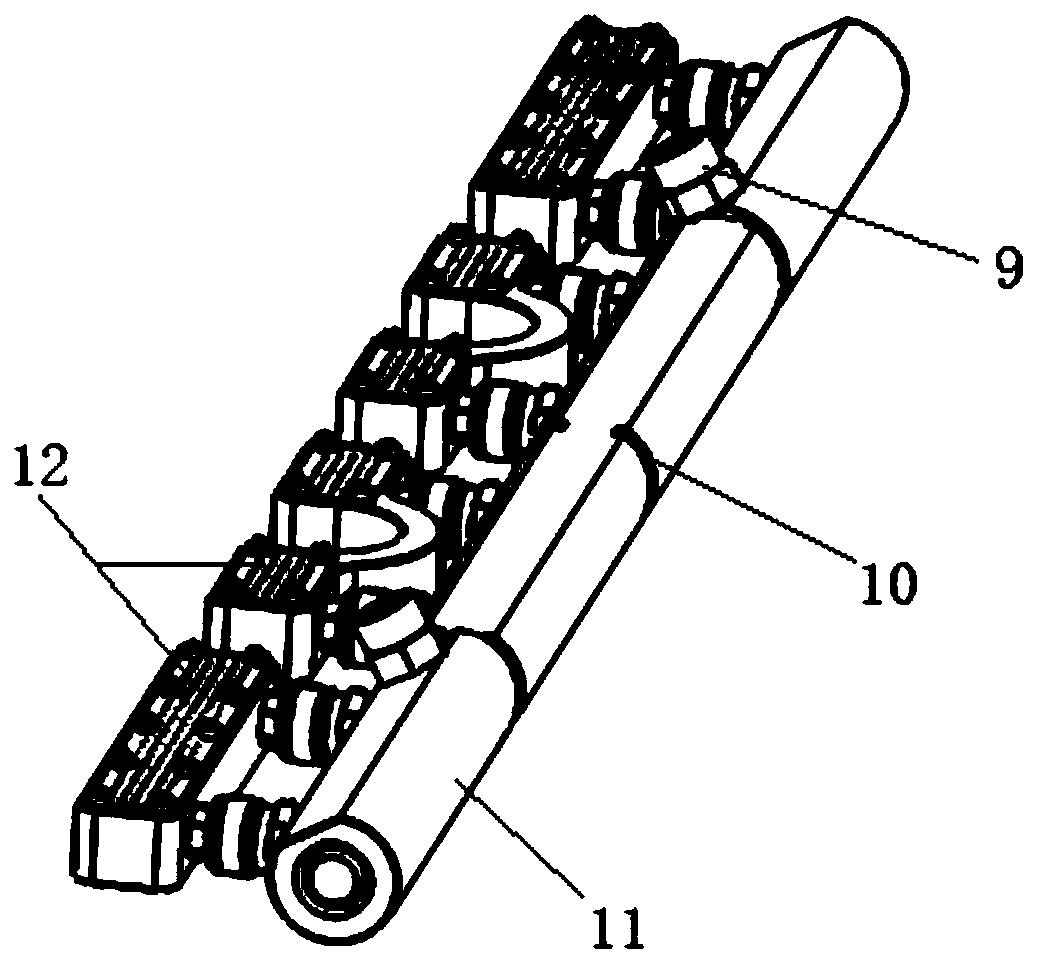

[0030] The follow-up cooling structure of the bilateral mechanical arm is applied between the upper mold frame 16 and the lower mold frame 17 of the hot forging machine, and is used for spraying cooling liquid toward the upper mold frame 16, combined with the attached figure 1 It can be seen that it includes a formwork connection base 1, a main connecting rod 3, a follower cylinder 7 and a nozzle module. The formwork connection base 1 is installed on the lower surface of the upper formwork, and the lower surface of the formwork connection base 1 is provided with several Each connecting joint 2 is connected to a main connecting rod 3, and the lower ends of all the main connecting rods 3 are connected to the nozzle module.

[0031] The upper end of the follower cylinder 7 is fixed to the upper mold frame, and the lower end is connected with the main connecting rod 3 near the lower end. The follower cylinder 7 stretches and pulls the main connecting rod 3 to rotate around the conn...

Embodiment 2

[0033] The relative positional relationship between the follower cylinder 7 and the main connecting rod 3 is further designed. The follower cylinder 7 and the main link 3 are located on both sides of the central axis of the upper mold base, forming a triangular structure with the upper mold base. When the upper mold base and the upper mold base When the lower mold base is separated, the nozzle module sprays coolant upwards. When the upper mold base and the lower mold base are closed, the follower cylinder 7 shrinks, pulling the main connecting rod 3 to move upward, and the main connecting rod 3 moves upward with the nozzle module. , the nozzle module always sprays coolant towards the heat concentrated area of the upper mold base, and when the mold clamping is completed, the follower cylinder 7 shrinks to the shortest stroke.

Embodiment 3

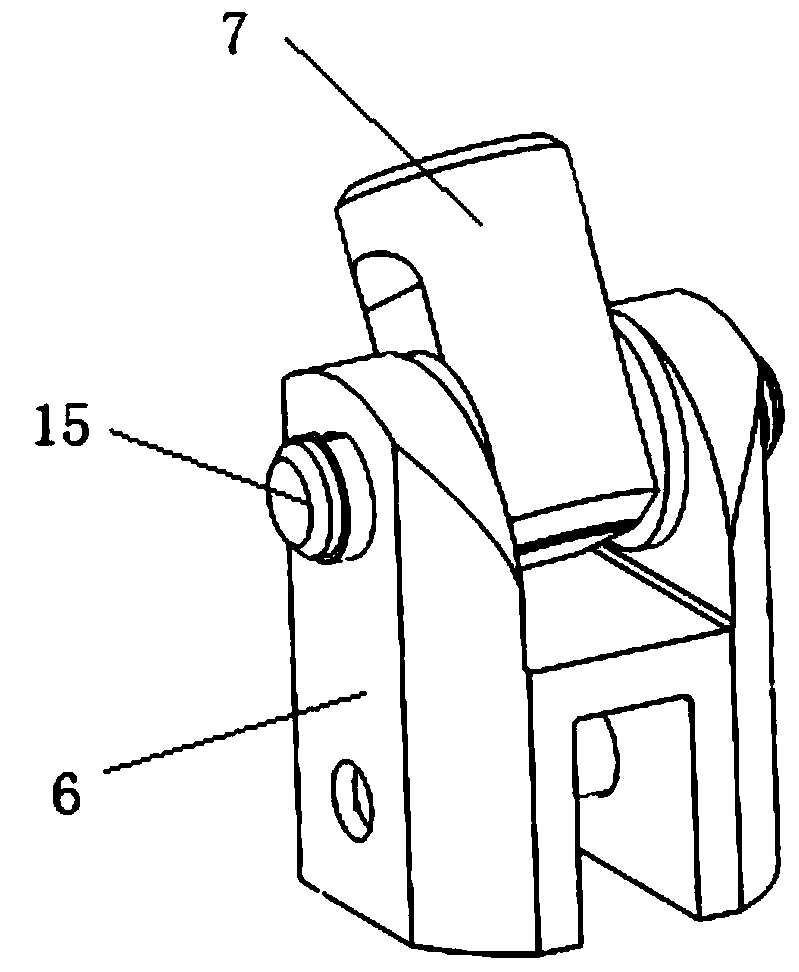

[0035] The structure and connection relationship of the main connecting rod 3 and the follower cylinder 7 are further designed. The upper end of the main connecting rod 3 and the connecting joint 2 under the formwork connecting base 1 are movable connections, and the connecting joint 2 includes two parallel connecting plates. Both the top of the main connecting rod 3 and the connecting plate are provided with connecting holes 4, and the top of the main connecting rod 3 is inserted between the connecting plates so that the connecting holes 4 are aligned, and inserted into the connecting holes 4 by hinge bolts to realize the flexible connection. The main connecting rod 3 can rotate around the hinge bolt, and the two ends of the hinge bolt are connected with nuts to prevent it from falling off from the connecting hole 4 .

[0036] The top of the follow-up cylinder 7 is connected with the upper mold frame through a movable joint 8, and the follow-up cylinder 7 can rotate in the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com