Automatic vibration control cabinet for precast concrete beam

A technology of prefabricated concrete and control cabinets, which is applied in the field of vibrating control cabinets. It can solve problems such as untimely discharge of heat, short-circuit shutdown, and dust entry in cooling holes, so as to eliminate potential safety hazards of conduction or leakage, prolong service life, and improve safety. Effects on Sexuality and Lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

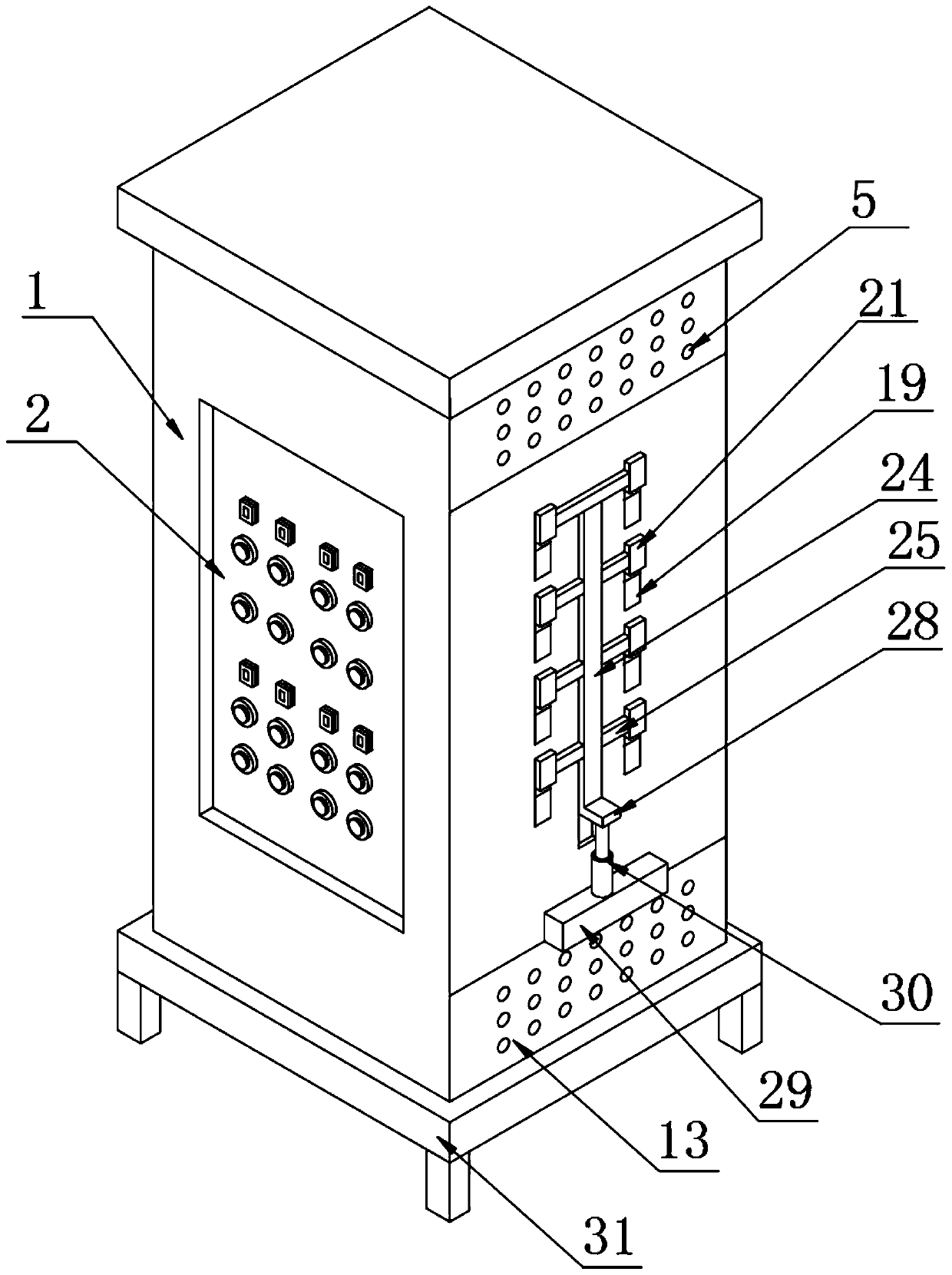

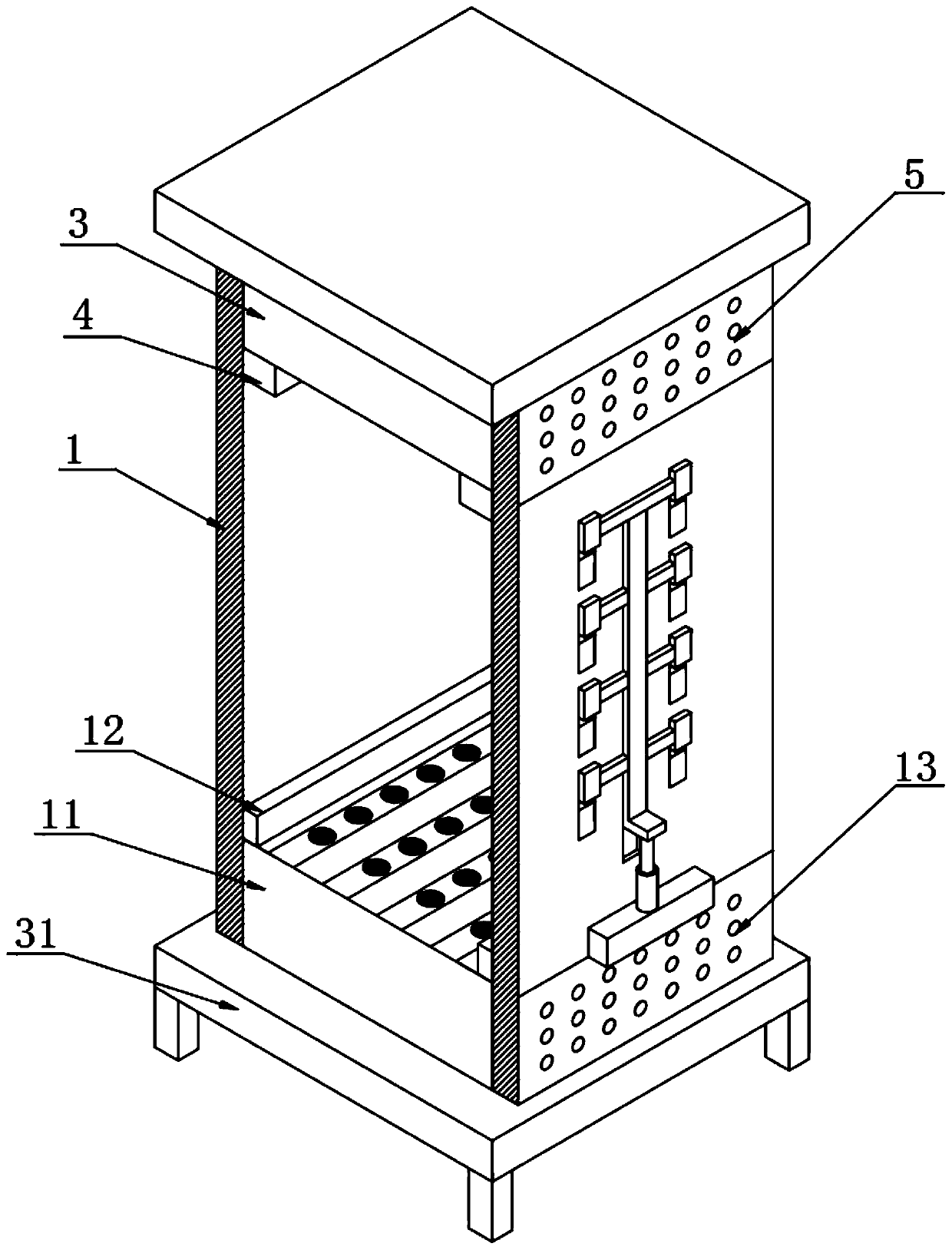

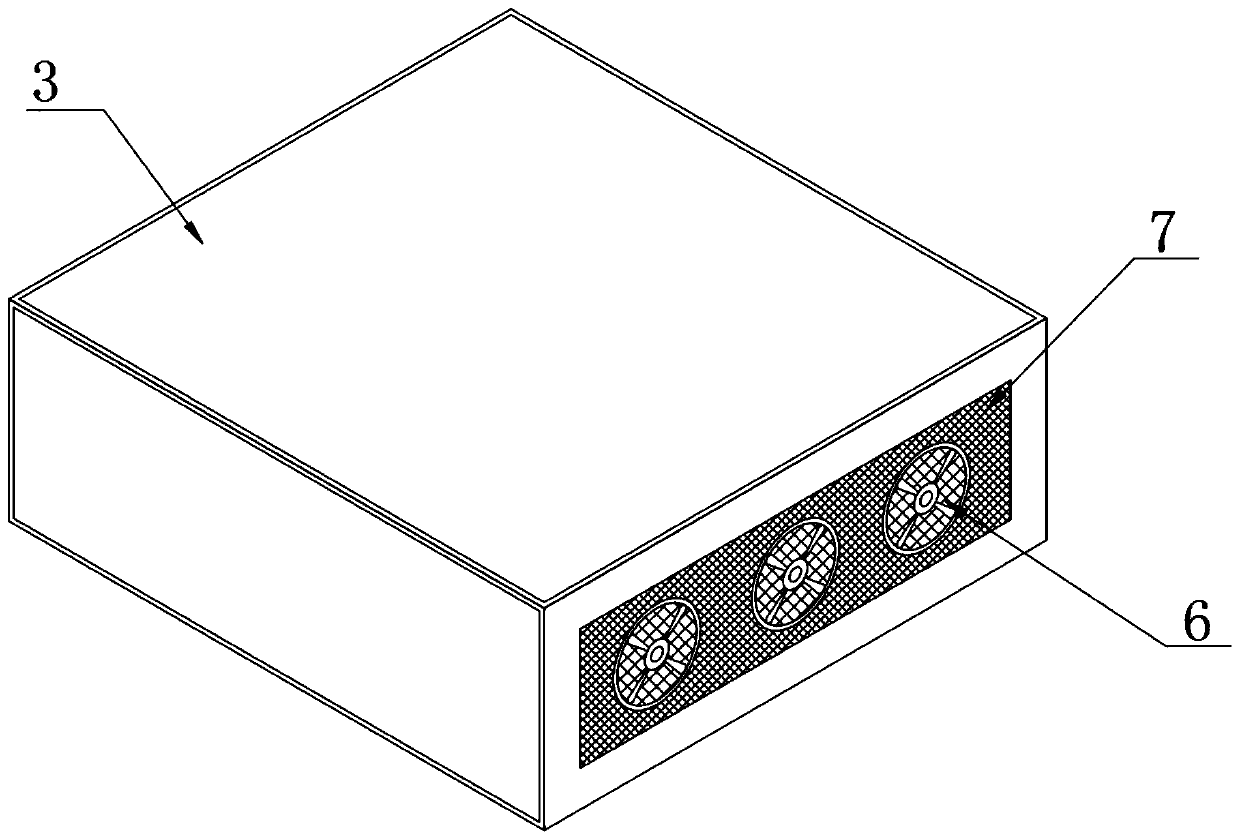

[0033] The present invention provides such as Figure 1-7 A prefabricated concrete beam automatic vibration control cabinet shown includes a cabinet body 1, a control body 2 is arranged inside the cabinet body 1, and a top dust removal box 3 is arranged on the top inside of the cabinet body 1, and the top dust removal box 3 3 both sides of the bottom end are provided with top fixing strips 4, the surface of both sides of the top of the cabinet body 1 is provided with top air intake holes 5, and both sides of the top dust removal box 3 are provided with first exhaust fans 6, so The number of the first air extraction fans 6 is six, and the six first air extraction fans 6 are divided into two groups and are evenly distributed on both sides of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com