Lifting ironing table for garment production line

A technology for production lines and ironing tables, applied to ironing boards, applications, household appliances, etc., can solve the problems of high labor intensity, laborious effort, and low efficiency, and achieve the effects of increasing contact time, improving heating effect, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

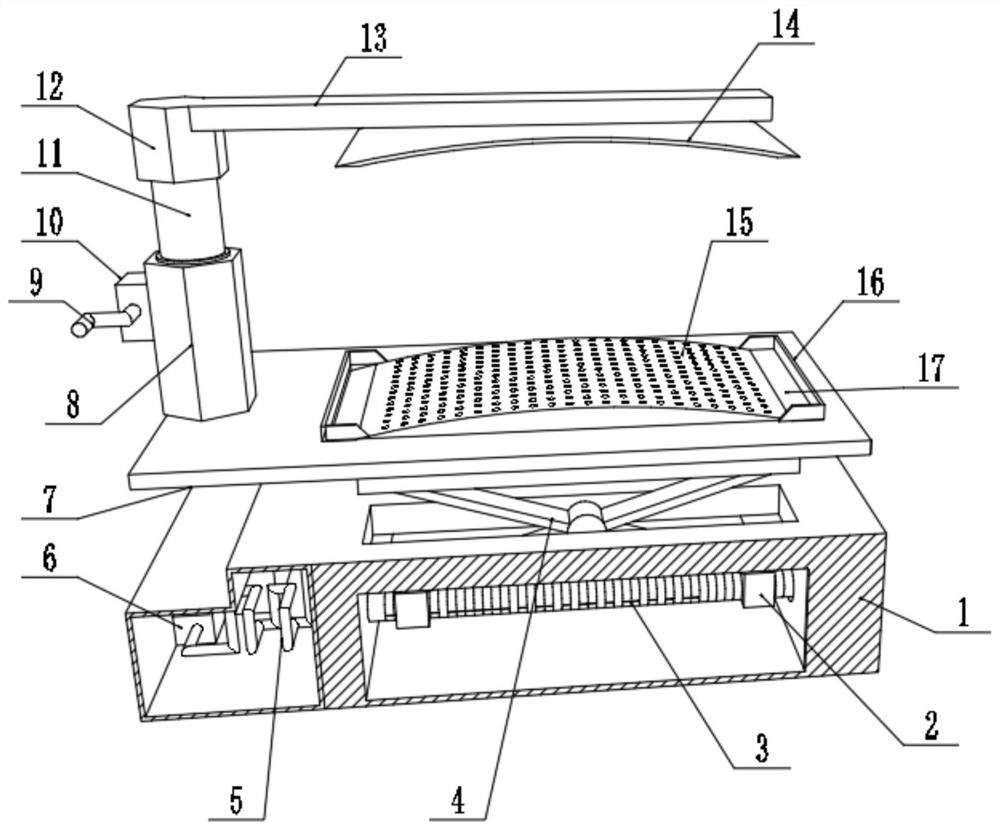

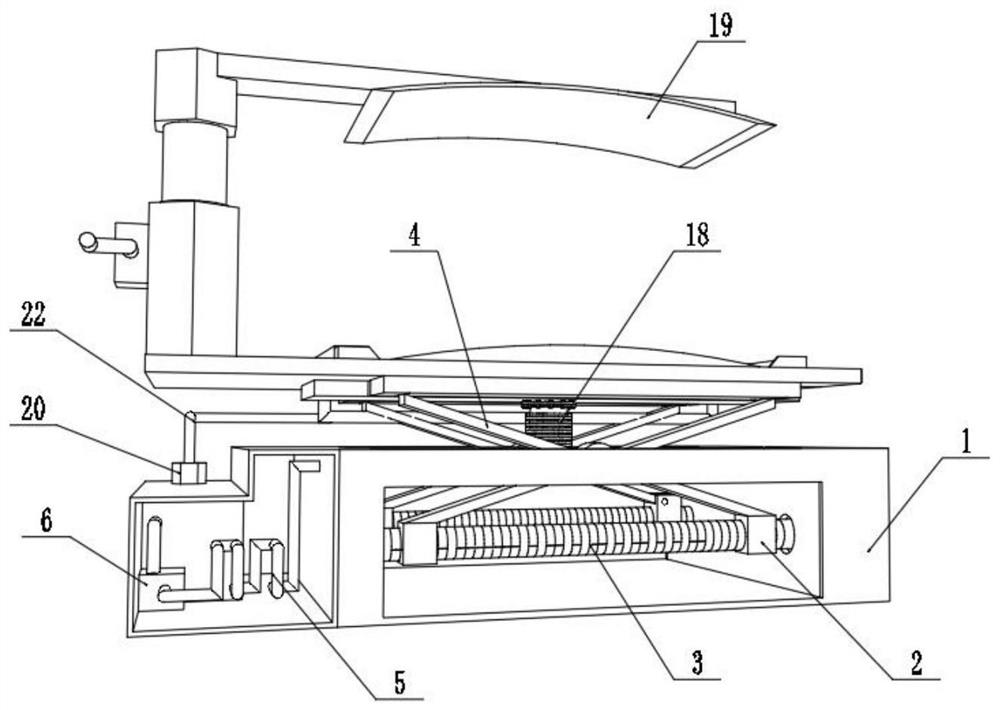

[0029] A lifting ironing table for a garment production line, such as Figure 1-4 As shown, it includes a base 1, an operating table 7 and an ironing table body 15;

[0030] Both sides of the top of the base 1 are provided with openings, and a lifting assembly is arranged in the opening. The operation table 7 is fixed on the top of the base 1 through the lifting assembly, and the ironing table body 15 is fixed on the top of the operation table 7 through screws. One side of the inner wall of the bottom end of the base 1 is fixed with a water tank by screws, and one side of the water tank is fixed with a booster pump 6 by screws, and the pumping end of the booster pump 6 is communicated with the inner bottom of the water tank through a conduit, increasing the The water outlet end of the pressure pump 6 is plugged with a heating pipe 5, and one end of the heating pipe 5 is communicated with the ironing table body 15 through a corrugated pipe 18. In this embodiment, preferably, th...

Embodiment 2

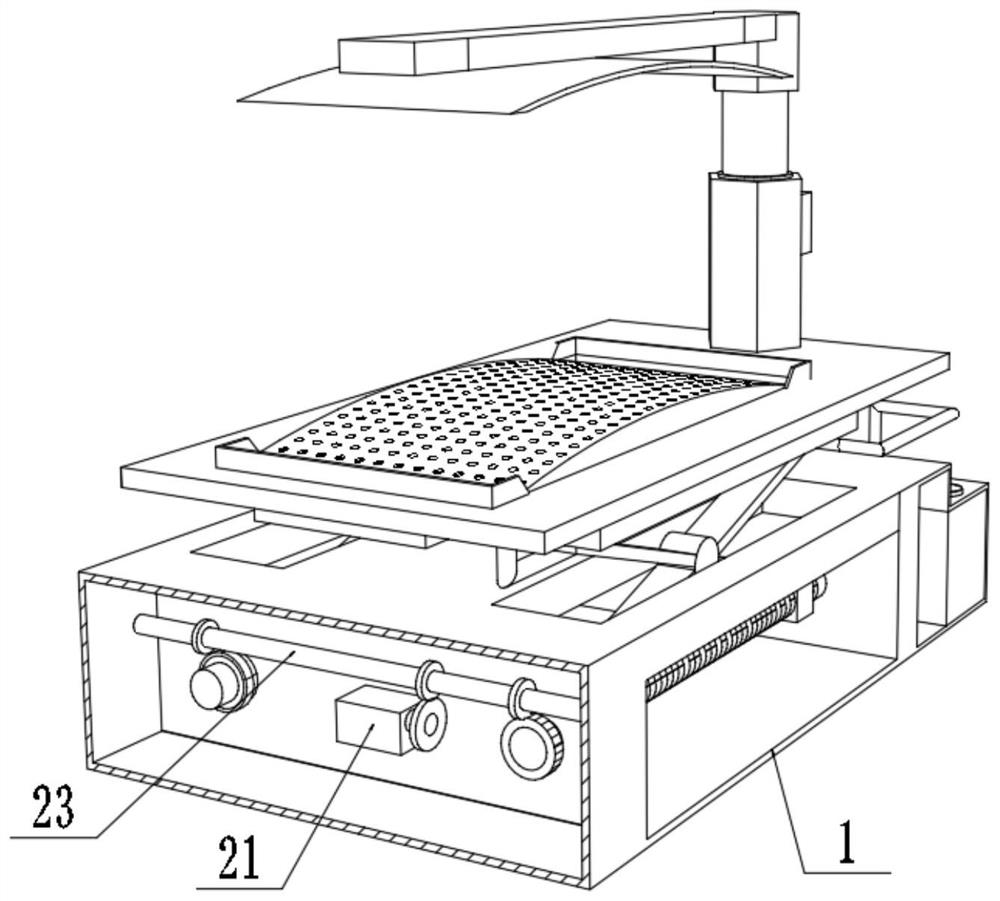

[0039] A lifting ironing table for a garment production line, such as figure 1 , figure 2 and Figure 5 As shown, in order to solve the problem that the steam can not be effectively recovered after dissipating, resulting in a large indoor humidity; this embodiment makes the following improvements on the basis of Embodiment 1: the top of the operating table 7 is welded with a sleeve 8, and the sleeve 8 is connected with a support rod 11 through the adjustment assembly, the top of the support rod 11 is welded with a connecting block 12, the side wall of the connecting block 12 is welded with a connecting frame 13, and the bottom end of the connecting frame 13 is welded with a water vapor recovery plate 14. This embodiment Among them, preferably, the water vapor recovery plate 14 is an arc structure, and the bottom end of the water vapor recovery plate 14 is welded with a metal sheet 19, and after steam ironing, it rises to the metal sheet 19 and condenses on the metal sheet 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com