Wind power heat energy exchange equipment

A technology of heat energy exchange and equipment, applied in the field of circulating heating system equipment, can solve problems such as difficulty in wind power grid connection, underutilization of wind power, difficulty in peak regulation and consumption of wind power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

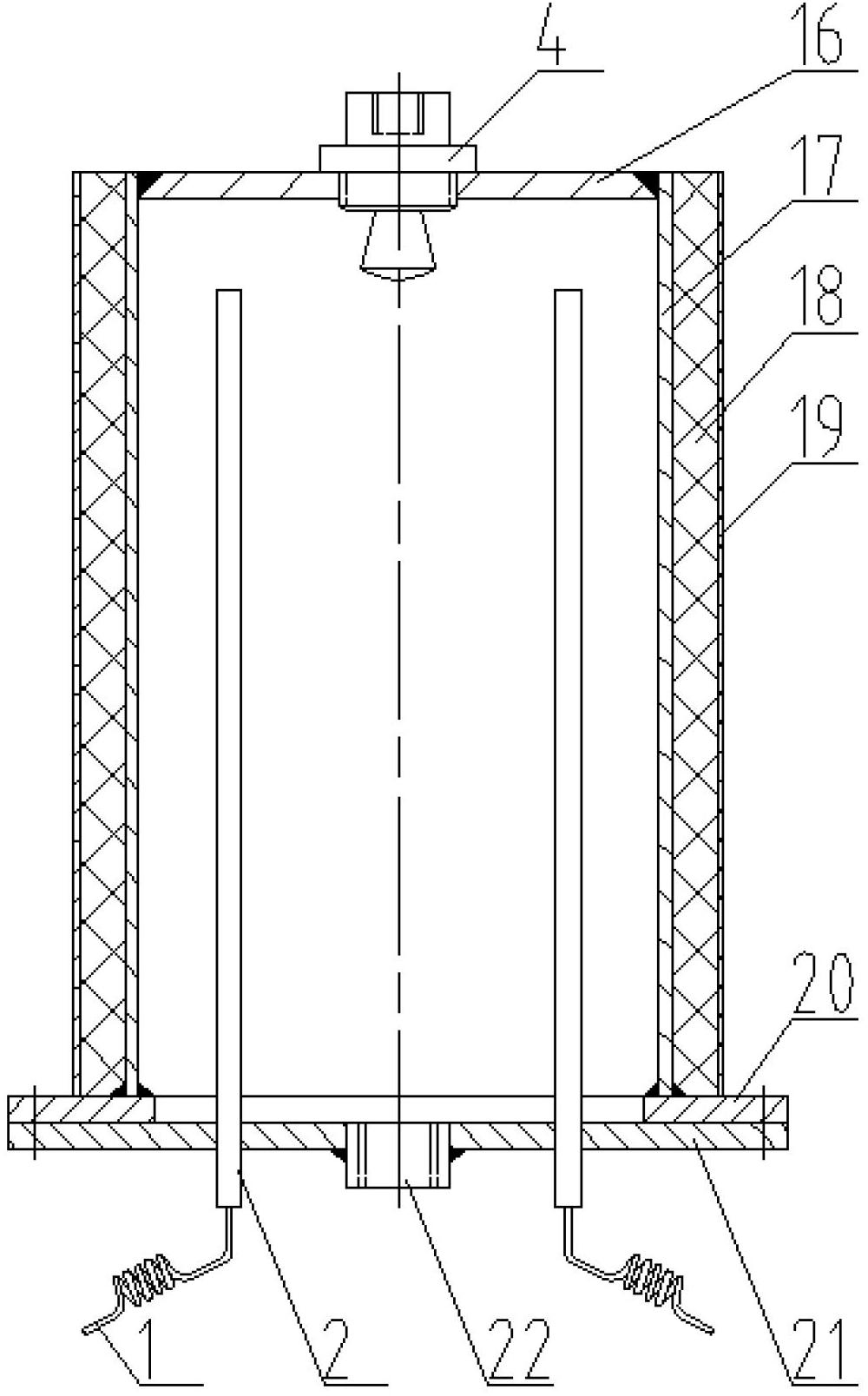

[0006] Embodiment 1, as attached figure 1 A kind of wind power heat exchange equipment of the present invention as shown, has a heat preservation container, and heat preservation container is made of upper sealing plate 16, seamless steel pipe 17, heat preservation layer 18, heat preservation layer protective casing 19, seamless steel pipe lower flange 20, and lower A lower end plate 21 connected by flange bolts is formed. An electric heater 2 is arranged in the heat preservation container, and a wire 1 of the electric heater extends out of the heat preservation container for connection with the wind power network. The lower end plate of the insulated container is provided with a steam outlet 22, and is provided with a threaded interface for communicating with a steam outlet pipeline. The heat-retaining container upper end also has the atomizer 4 that stretches in the heat-retaining container. The electric energy that wind power generation sends out like this, just can suppl...

Embodiment 2

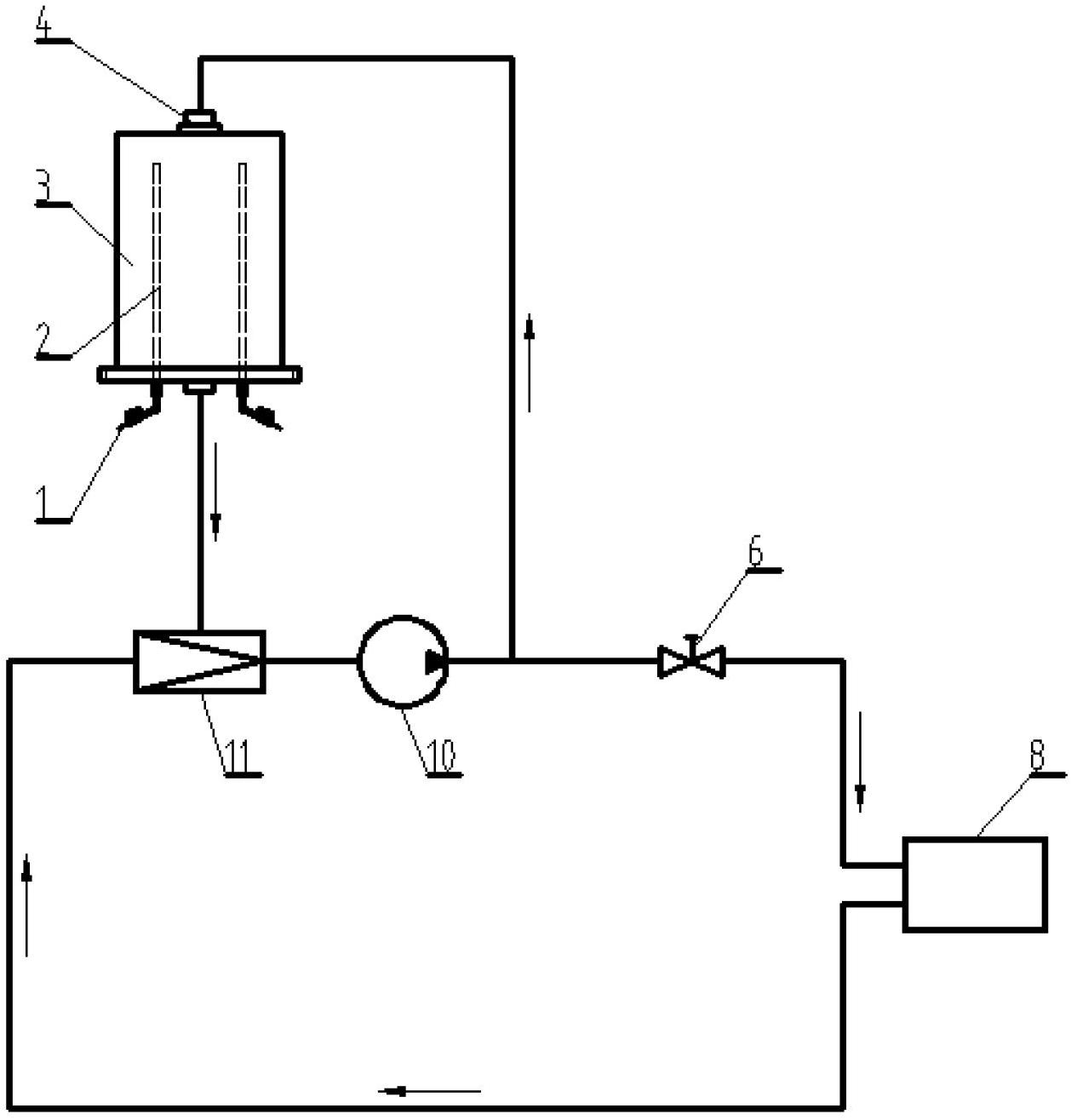

[0007] Embodiment 2, as attached figure 2 Shown is a kind of wind power thermal energy exchange heating equipment of the present invention (refer to figure 1 ), there is a wind power heat exchange equipment for generating steam, the wind power heat exchange equipment has a thermal insulation container 3, the thermal insulation container is equipped with an electric heater 2 and a steam outlet, and the upper end of the thermal insulation container is also equipped with an atomizer 4 extending into the thermal insulation container . The input end of the heater is connected to the output end of the wind power generation equipment through a wire 1 . The electric energy generated by the wind power generation equipment can be supplied to the heater through the wire for heating, and the water mist sprayed from the atomizer absorbs heat in the stable high-temperature zone of the heat preservation container and instantly vaporizes into steam (completes the phase change process), form...

Embodiment 3

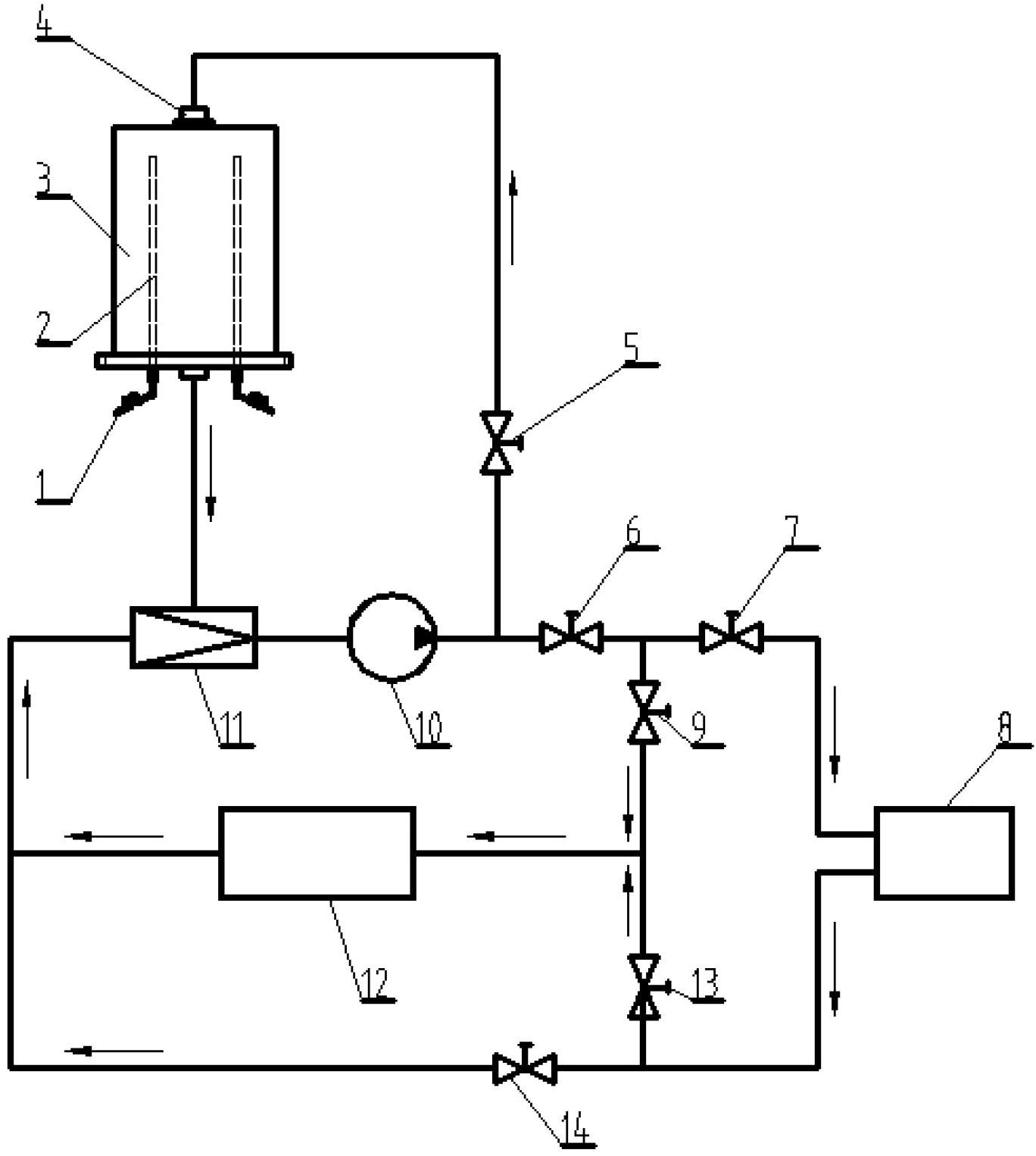

[0008] Embodiment 3, as attached image 3 A wind-electric heat exchange heating device with energy storage shown in the present invention has a wind-electric heat exchange device for generating steam. The electric heat exchange device has a thermal insulation container 3, and the thermal insulation container is provided with an electric heater 2 and a steam outlet 22 for heat preservation. The upper end of the container also has an atomizer 4 extending into the heat preservation container. The input end of the electric heater is connected with the output end of the wind power generation equipment through a wire 1 . The electric energy generated by the wind power generation equipment can be supplied to the heater through the wire for heating, and the water mist sprayed from the atomizer absorbs heat in the stable high-temperature zone of the heat preservation container and instantly vaporizes into steam (completes the phase change process), forming a high-energy It can be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com