A telescopic tailpipe seat

A liner seat, telescopic technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of lost hands, affecting the progress of the project, unable to meet the needs of on-site construction, etc., to achieve enhanced reliability and tight and reliable contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

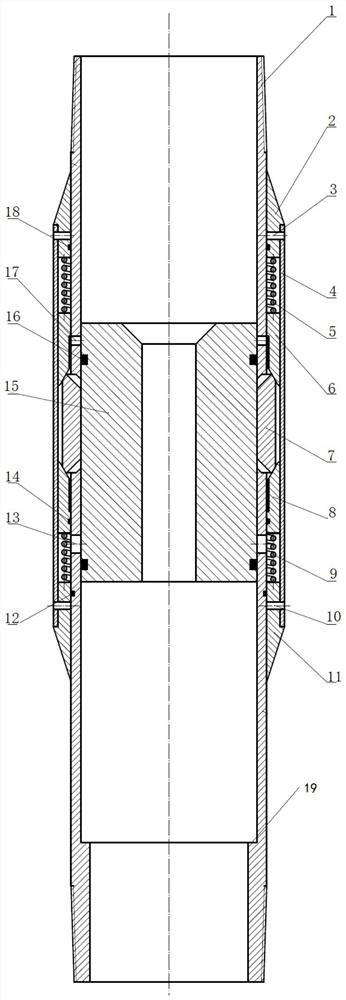

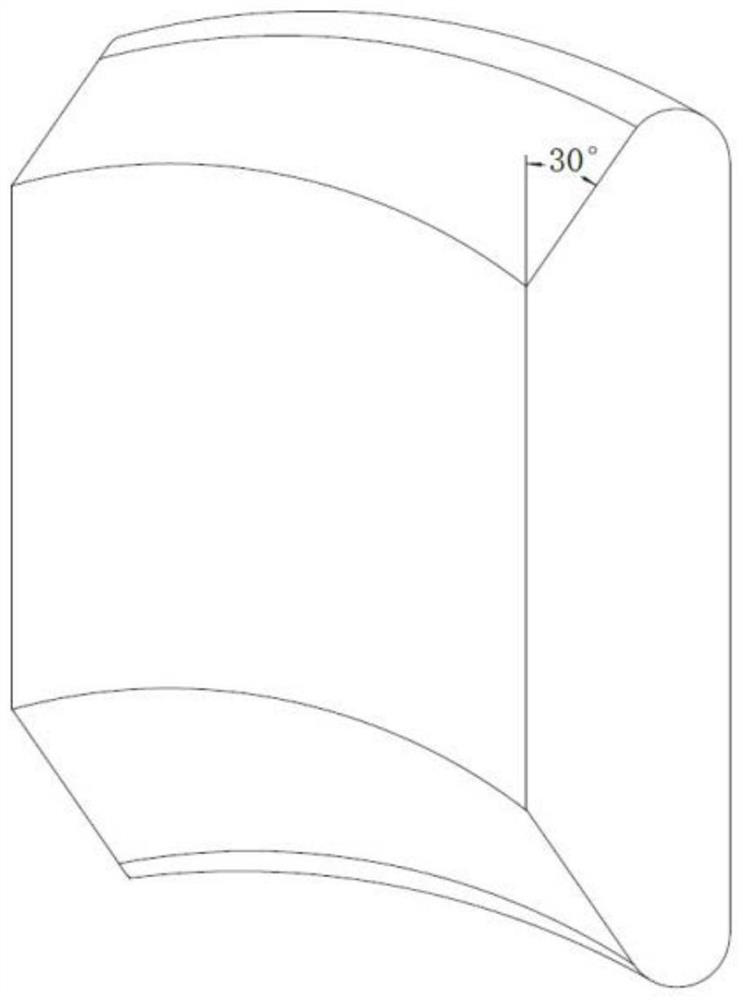

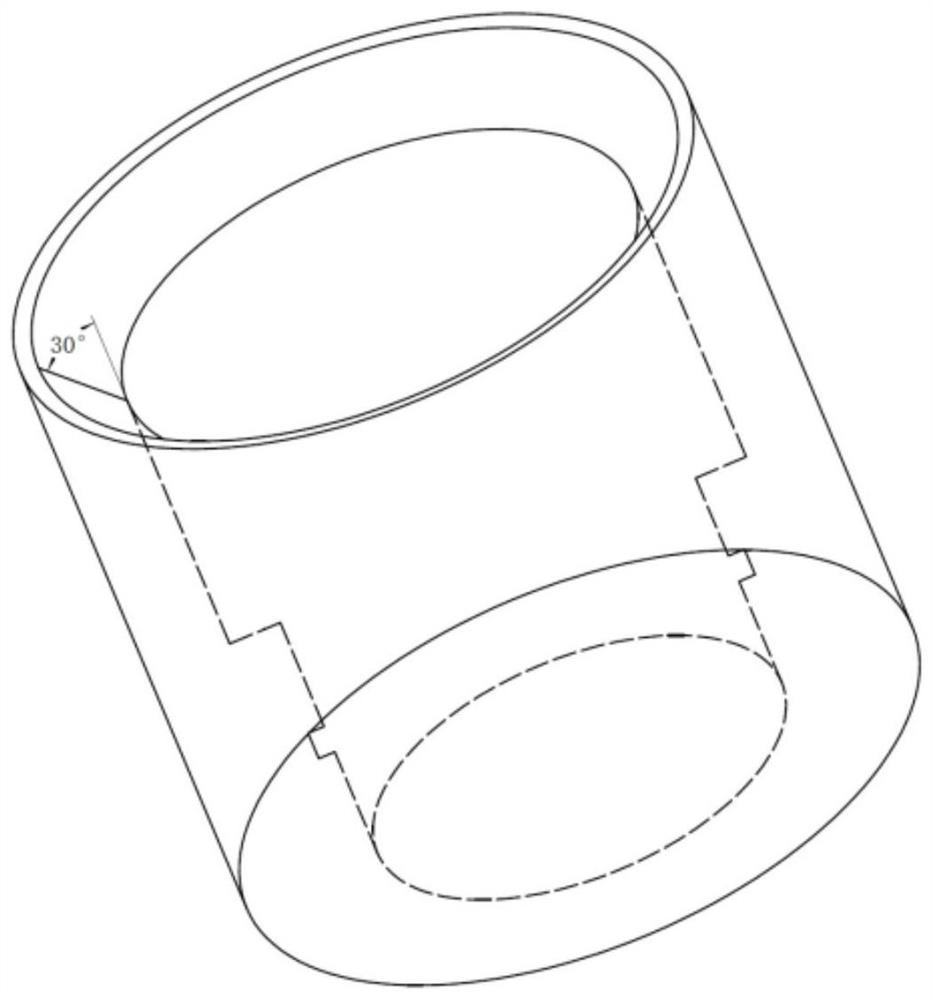

[0029] figure 1 Structural sectional view of the telescopic tail tube seat provided for the embodiment of the present invention; figure 2 Schematic diagram of the structure of the annular seat hanging step of the telescopic tail tube seat provided by the embodiment of the present invention; image 3 A structural schematic diagram of the ejection ring of the telescopic tail tube seat provided by the embodiment of the present invention; as Figure 1~3 As shown, a telescopic tail tube seat provided in this embodiment includes a body 1, an upper back ring 2, a lock ring sleeve 4, an annular seat hanging step 7, and a lower back ring 11. The body 1 is hollow and cylindrical structure, the upper back ring 2 and the lower back ring 11 are sleeved on the body 1 respectively, the lock ring sleeve 4 connects the upper back ring 2 and the lower back ring 11 together, and the upper end of the lock ring sleeve 4 is connected to the The upper back ring 2 and the body 1 are fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com