Hollow plastic plate and manufacturing method thereof

A technology of plastic sheet and manufacturing method, which is applied in the field of materials, and can solve the problems of weak stress bearing of the sheet, reduction of thermal insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

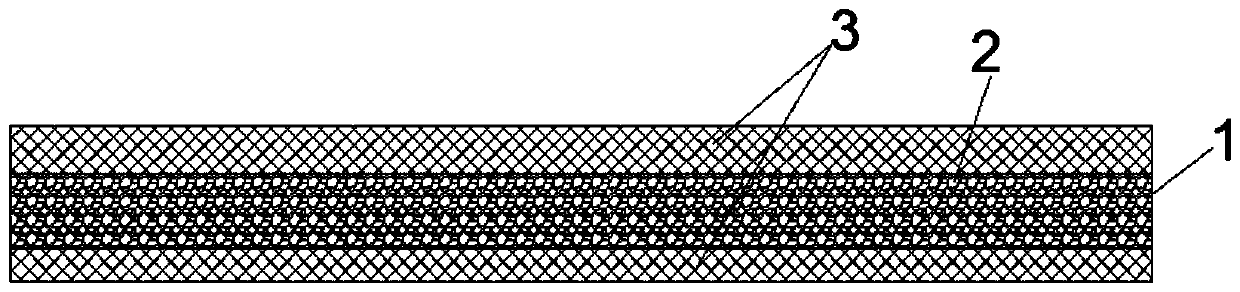

[0019] A hollow plastic plate, comprising a hollow plate 1 in the middle, a number of disordered air bubbles 2 are formed in the hollow plate 1, solid plates 3 are fixed on the top and bottom of the hollow plate 1. The hollow plate 1 and the solid plate 3 are glued and fixed.

[0020] The above-mentioned manufacturing method of a hollow plastic sheet comprises the following steps:

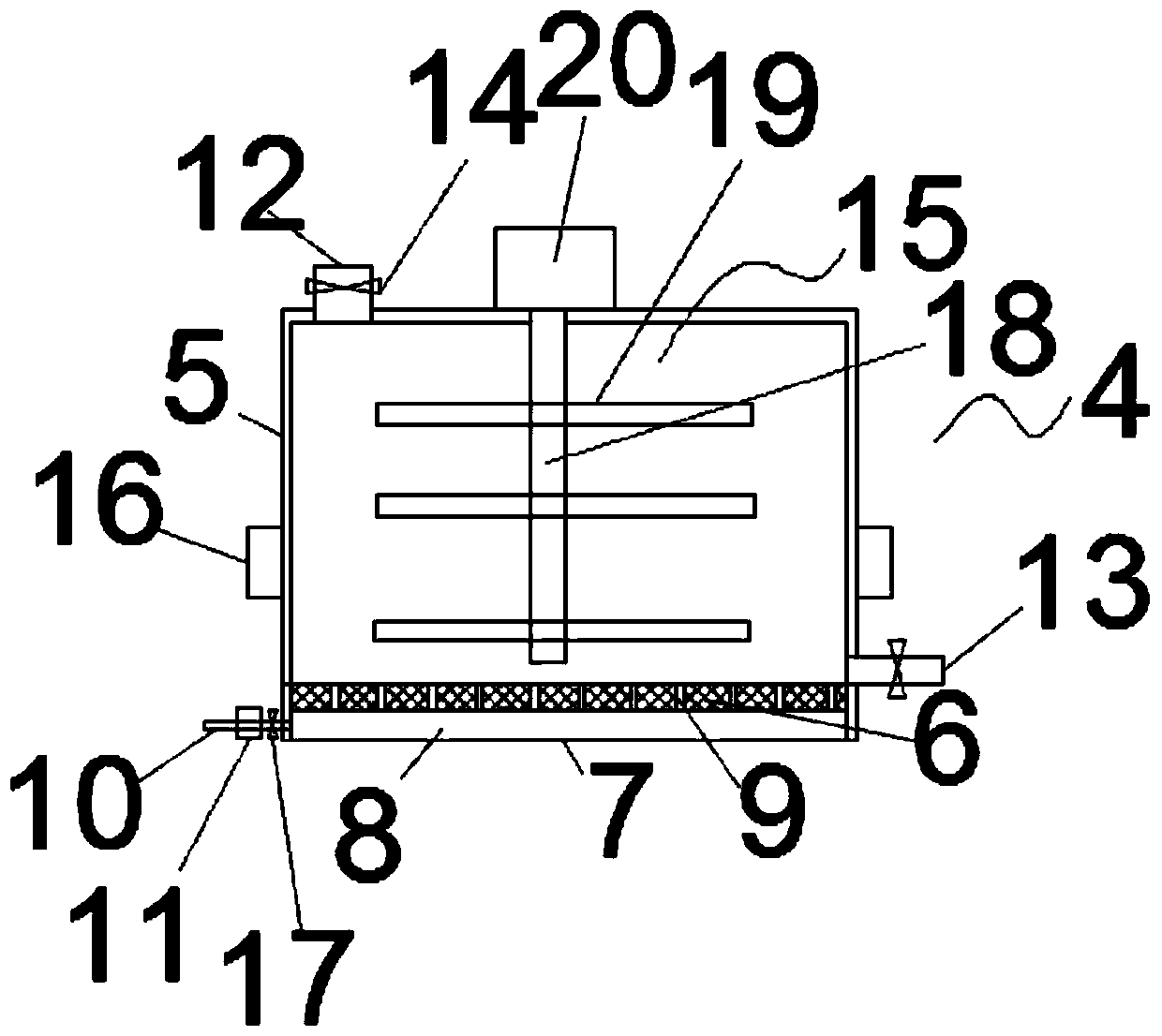

[0021] Step 1. Put the raw material of the plastic sheet into the heating and melting device 4; the heating and melting device 4 includes a shell 5, the bottom of the shell 5 is an electric heating base 6, and the bottom of the electric heating base 6 is fixed with a closing plate 7, the closing plate An air cavity 8 is formed between 7 and the electric heating base 6; the electric heating base 6 is formed with a number of microholes 9 connecting the shell 5 and the air cavity 8; the air cavity 8 is connected with an air pump 11 and an air valve 17 through the air pipe 10; The top of the housing 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com