Paint spraying device for surface of machined steel plate

A technology of mechanical processing and steel plate, which is applied in the direction of spraying device, etc., can solve the problems of insufficient and thorough spraying treatment on the painted surface of steel plate, small spraying range, etc., and achieve the effect of fully uniform spraying effect, lifting range, and high-efficiency spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

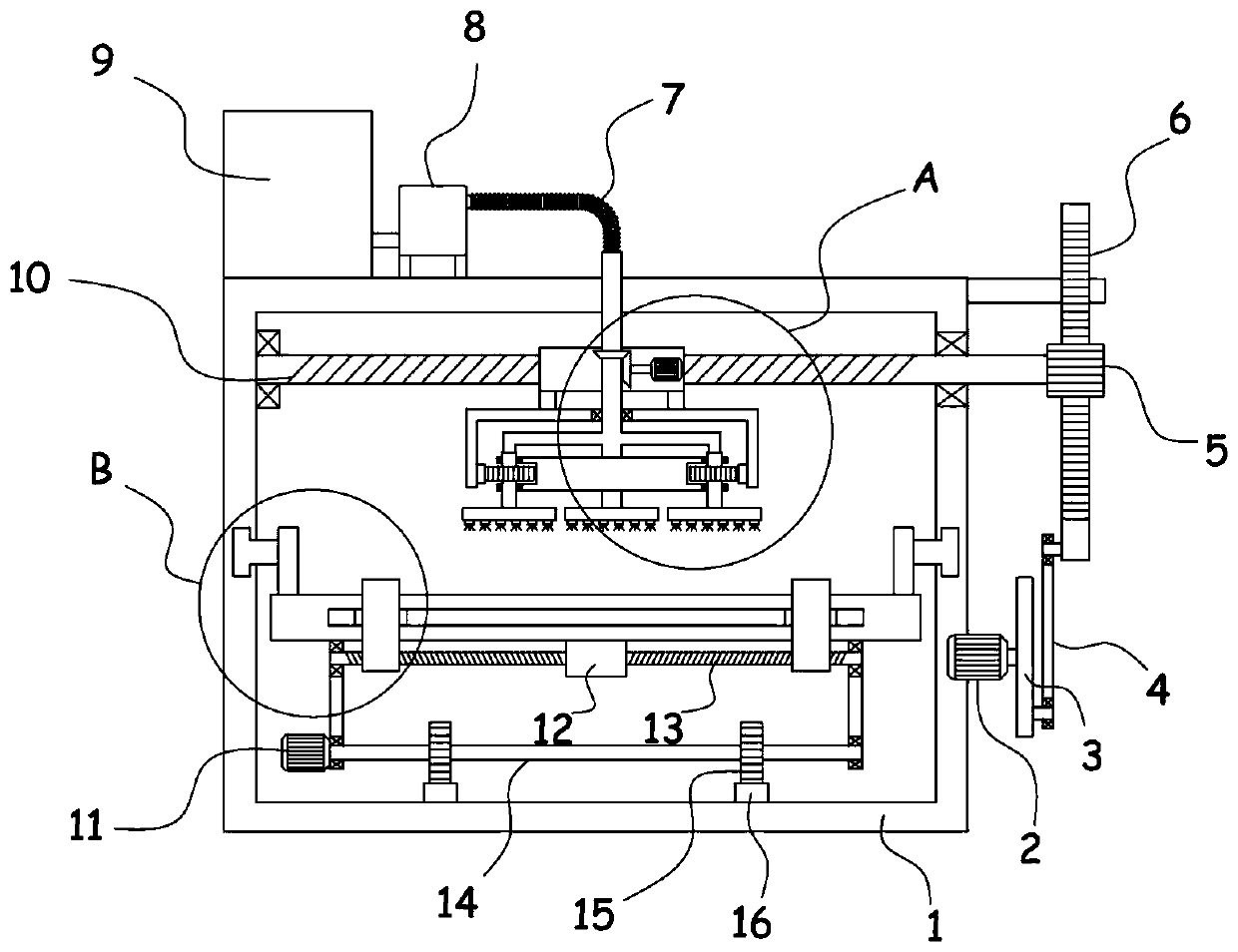

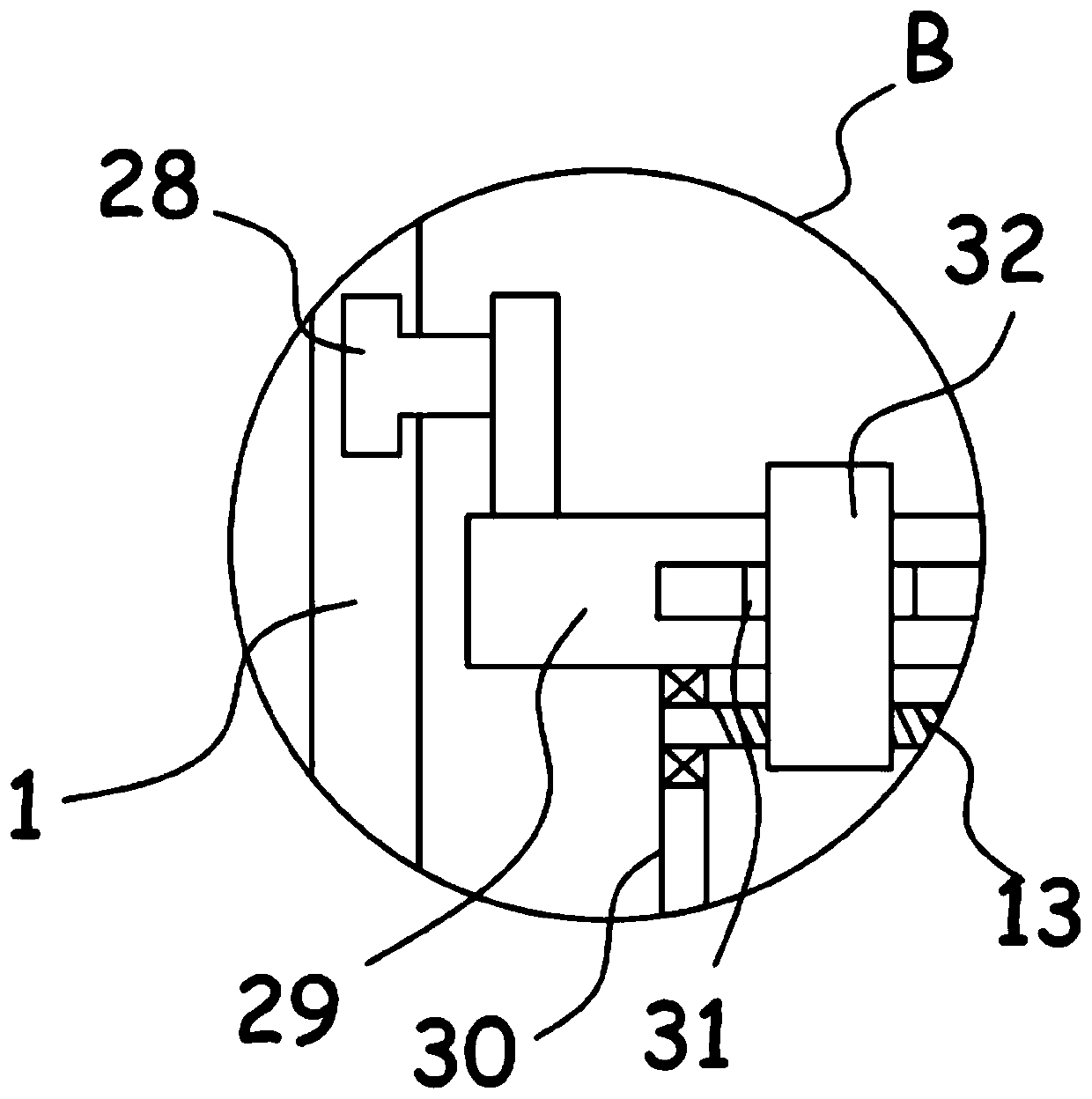

[0025] see Figure 1-4 , a kind of mechanically processed steel plate surface painting device, comprising a fixed frame 1, the top of the fixed frame 1 is fixed with a conveying pump 8 and a paint box 9 connected to each other, and a horizontally arranged support frame 29 is slidably installed on the fixed frame 1, and the support frame 29 is provided with a clamping mechanism for fixing the steel plate. The fixed frame 1 is driven and connected with a threaded block 20 through a reciprocating mechanism. The frame 22 is provided with a rotary painting mechanism communicating with the delivery pump 8 on the turret 22 , and a translation mechanism for driving the turret 22 to move laterally is provided on the fixed frame 1 .

[0026] The device realizes the clamping and fixing of the steel plate through the clamping mechanism to ensure the stability of the steel plate during the painting process. Specifically, the clamping mechanism includes a pair of clamping sleeves 32 sliding...

Embodiment 2

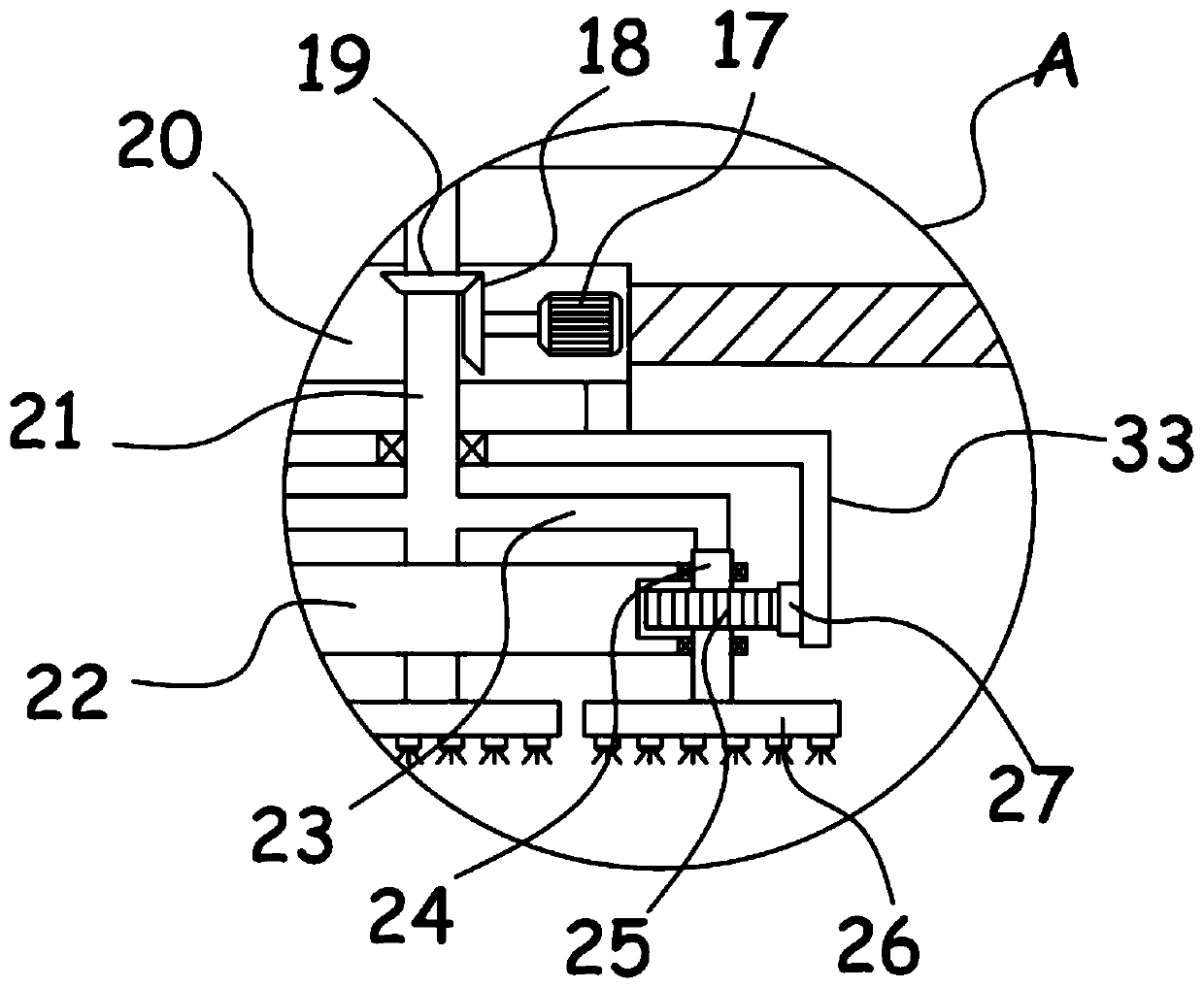

[0031] On the basis of Embodiment 1, in addition, the rotary painting mechanism also includes a motor III17 fixed on the threaded sleeve block 20, the output shaft of the motor III17 is coaxially fixed with a bevel gear I18, and the bevel gear I18 is meshed and connected with a sleeve fixed on the The bevel gear II19 on the hollow shaft I21, the rotary painting mechanism also includes an inner ring gear 27 fixed on the inner wall of the hanger 33, and the inner ring gear 27 is meshed with a pinion gear 25 sleeved and fixed on the hollow shaft II24.

[0032] In the process of paint spraying, the motor III17 drives the bevel gear I18 to rotate, and the bevel gear I18 drives the bevel gear II19 meshed with it to rotate, and then the hollow shaft I21 drives the turret 22 to rotate, and the pinion gear 25 on the turret 22 is in contact with the internal The ring gear 27 is meshed and driven, and then the hollow shaft II24 is rotated around the hollow shaft I21 center line while rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com