Teaching Method of Subsidence Compensation for Car Door Assembly

A teaching method and vehicle door technology, applied in the field of visual inspection, can solve the problems of affecting the production rhythm, many influencing factors, complex processes, etc., and achieve the effect of reducing the amount of manual work, improving economic benefits, and increasing the amount of automobile assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A teaching method for vehicle door assembly settlement compensation, comprising the following steps:

[0031] 1) When the car body reaches the actual assembly position, the robot grabs the door and installs it on the car body;

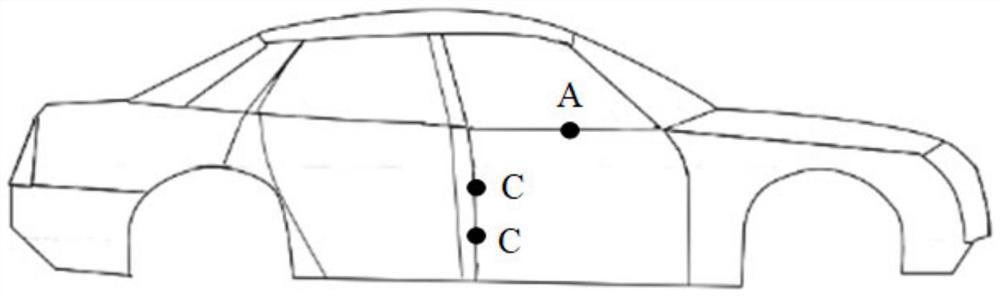

[0032] Note the gap line between the longitudinal edge of the door and the car body as the reference line; select the positioning point C from the door on one side of the reference line;

[0033] Select the anchor point A from the waistline of the car door; figure 1 As shown, take the car front door selection point as an example;

[0034] The number of anchor points C is greater than or equal to 2; the number of anchor points A is greater than or equal to 1;

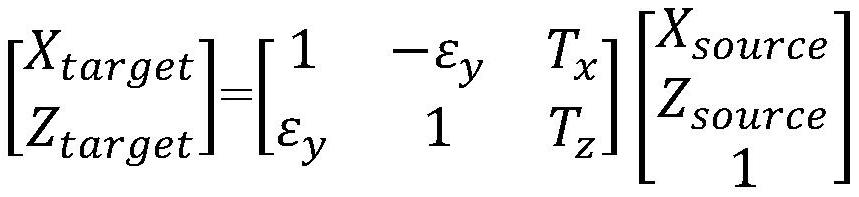

[0035] 2) The visual sensor obtains the structured light images of the positioning point A and the positioning point C respectively, and calculates the coordinate data of each point (X source ,Y source ,Z source );

[0036] 3) A counterweight is installed on the door, and the door se...

Embodiment 2

[0049] A teaching method for subsidence compensation of vehicle door assembly. This embodiment takes the rear door of a vehicle as an example, including:

[0050] 1) When the car body reaches the actual assembly position, the robot grabs the door and installs it on the car body;

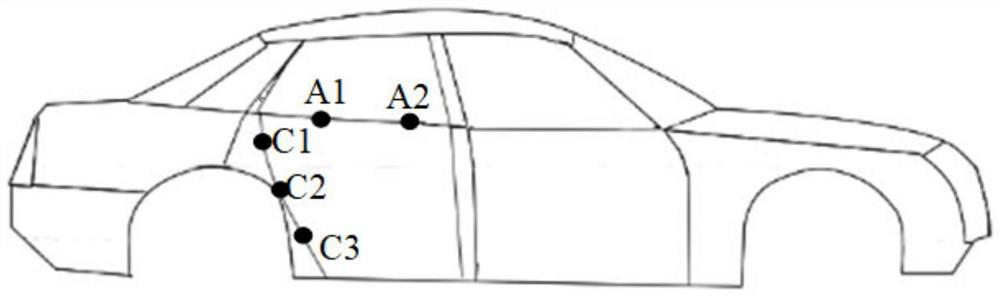

[0051] Such as figure 2 As shown, note the gap line between the longitudinal edge of the rear door and the car body as the reference line; select three positioning points C (C1, C2, C3) from the rear door on one side of the reference line;

[0052] Select anchor point A (A1, A2) from the waistline of the car door;

[0053] 2) The visual sensor acquires the structured light images of each positioning point A and positioning point C respectively, and calculates the coordinate data of each point (X source ,Y source ,Z source );

[0054]3) A counterweight is installed on the door, and the door settles under the action of the counterweight; the visual sensor acquires the structured light images of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com