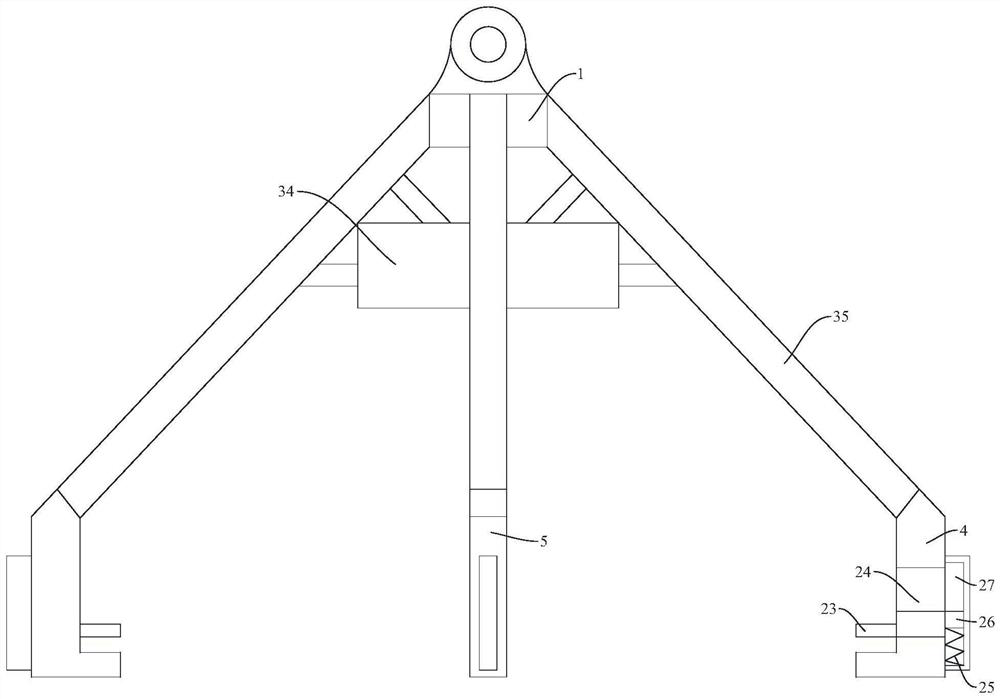

Hoisting mechanism for steel processing and production

A hoisting and steel technology, applied in the field of steel processing and production, can solve the problems of short service life, low stability, limited safety, etc., and achieve the effect of improving safety, improving stability and firmness, and improving hoisting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

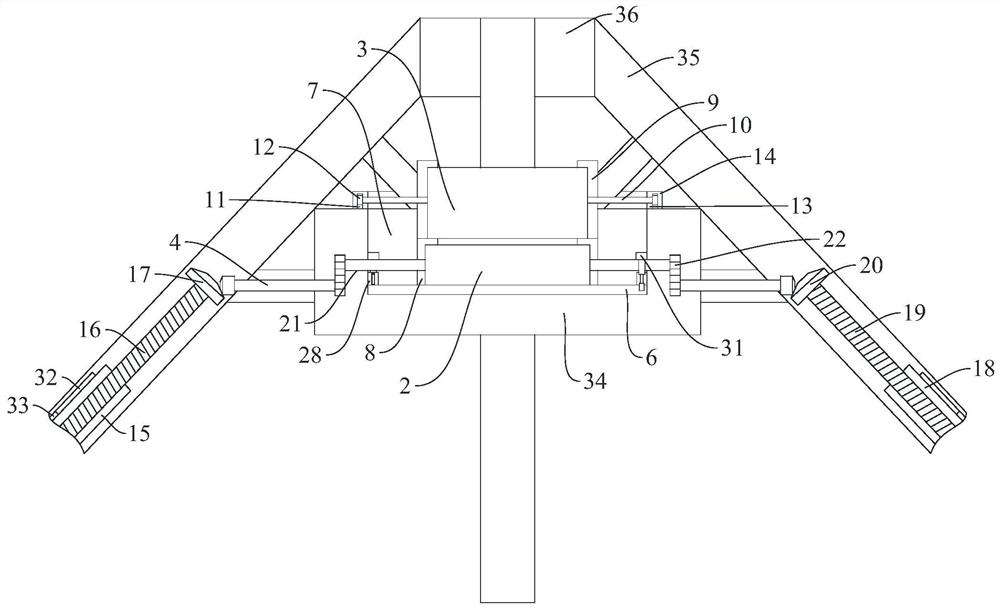

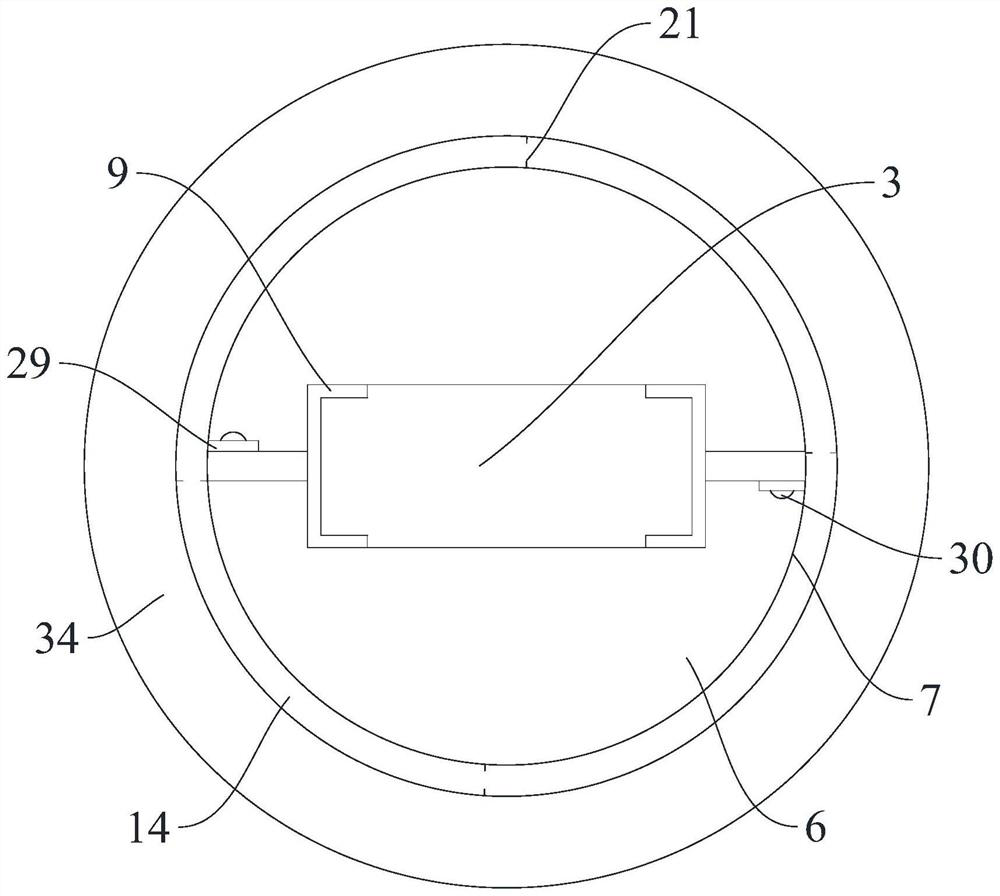

[0025] Embodiment: People control the drive motor 2, the adjustment motor 3 and the electric hydraulic strut 30 respectively through an external switch, and use the adjustment motor 3 to adjust the angle of the entire middle adjustment disc 6 and the drive motor 2, so that they are respectively different from the first The linkage control mechanism and the second linkage control mechanism switch and connect the transmission, so that it can control the first lateral telescopic bracket 4 and the second lateral telescopic bracket 5 independently, when the first lateral telescopic bracket 4 and the second lateral telescopic bracket If the heights of the brackets 5 are the same, they will be lifted synchronously; when the heights of the first lateral telescopic bracket 4 and the second lateral telescopic bracket 5 are different, they will be used for lifting to clamp and fix the steel plate.

[0026] Furthermore, in order to cooperate with the top adjustment and enhance the limit st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com