Deck barge cargo-blocking coaming structure

A coaming and deck technology, which is applied in the field of ships, can solve the problems of large longitudinal cargo coaming structure size, increase ship construction cost, increase the weight of hull steel materials, etc., to facilitate installation and transportation, reduce weight, and save construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

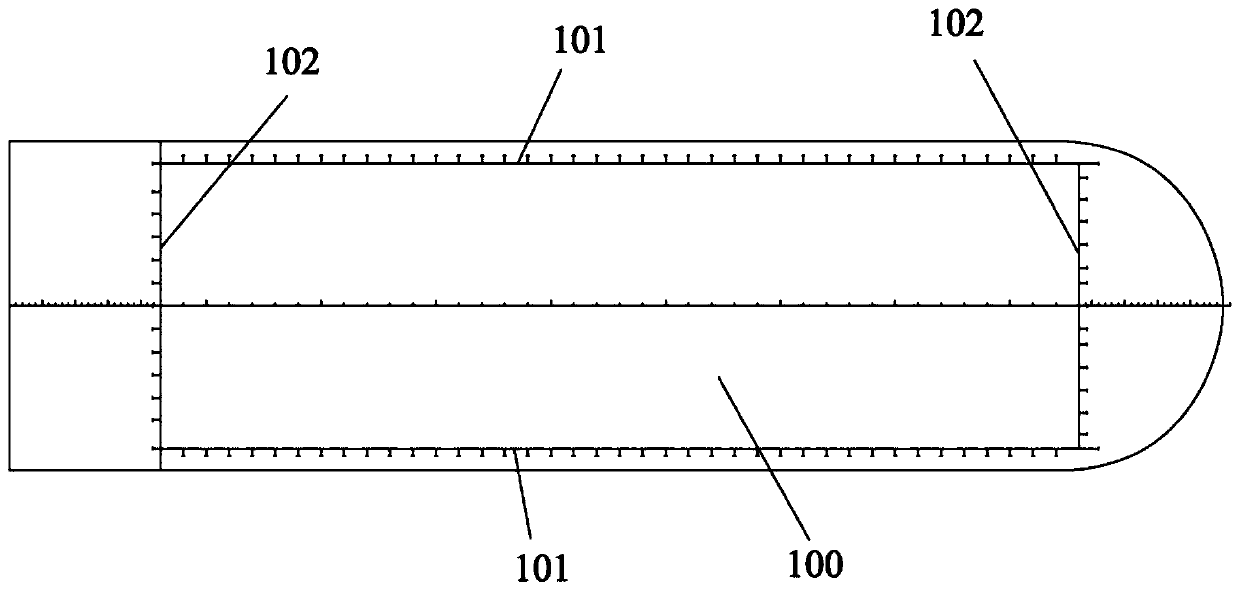

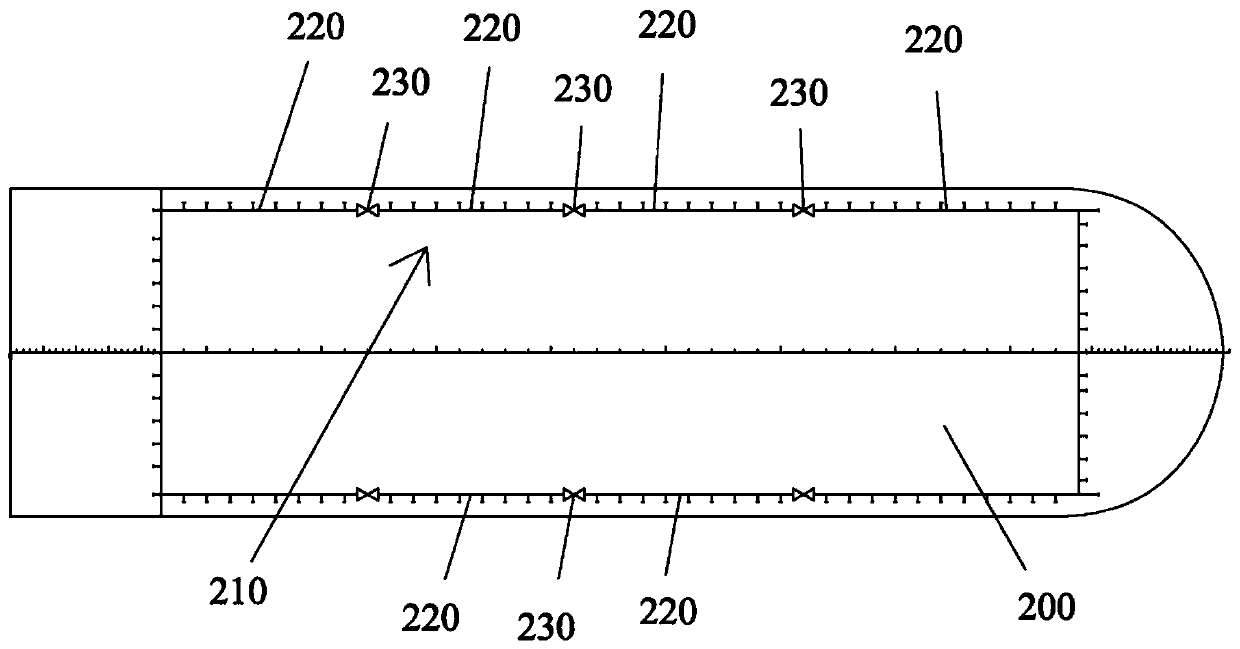

[0025] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, a deck barge cargo coaming structure, which includes a longitudinal cargo coaming 210 fixed to the ship deck 200, the longitudinal cargo coaming includes several longitudinal coaming segments 220, adjacent longitudinal coaming The segments 220 are not directly connected; the longitudinal shroud segments 220 are discontinuously distributed on the deck of the ship; adjacent longitudinal shroud segments 220 are provided with shroud joints 230 .

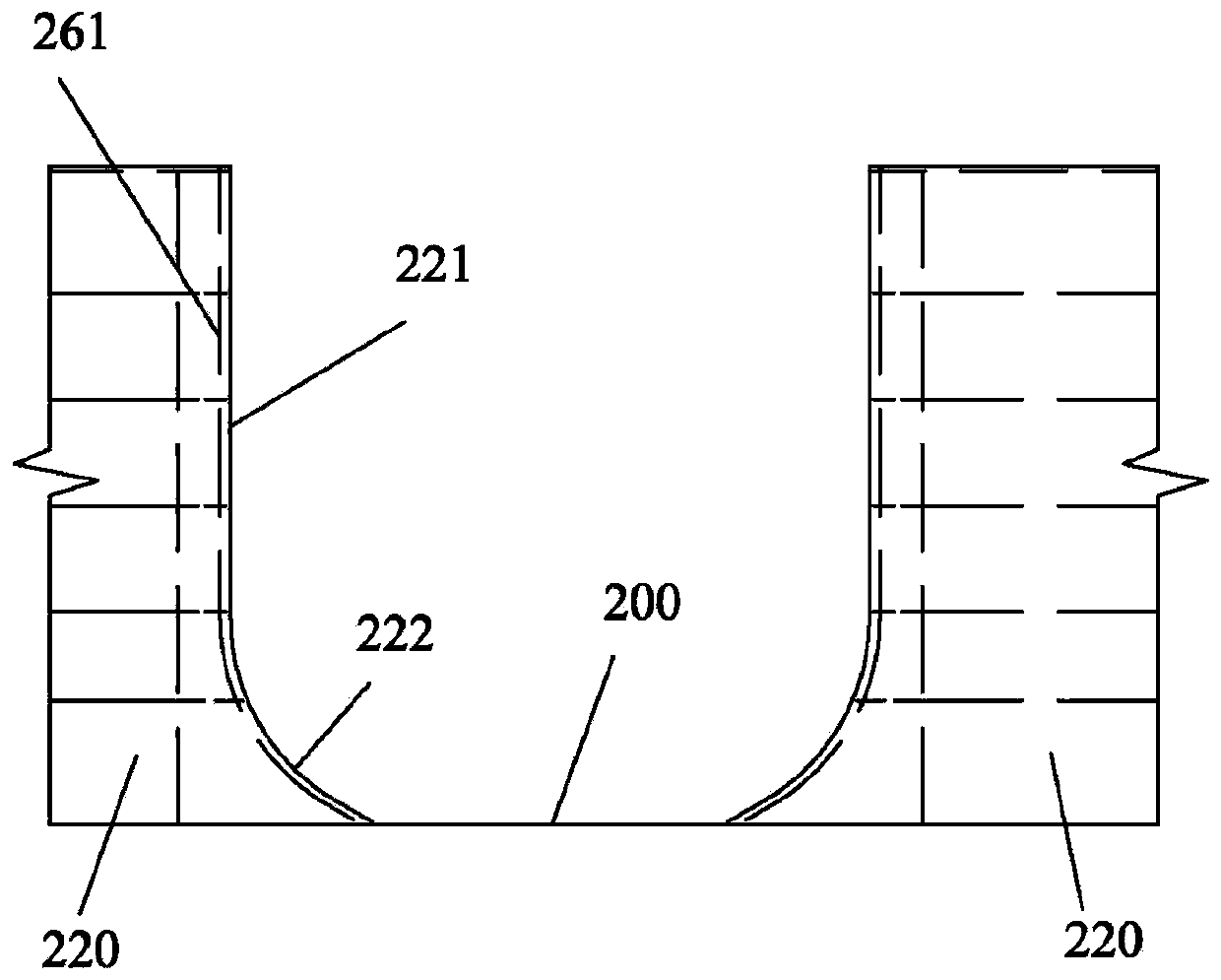

[0026] The end of the longitudinal shroud segment 220 includes a vertical end 221 and an oblique end 222, the oblique end 222 is connected to the bottom of the vertical end 221, the oblique end 222 extends obliquely towards the outside of the longitudinal shroud segment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com