Adjustable film pasting pad

An adjustable, film-sticking technology, applied in packaging and other directions, can solve the problems of inability to stick film, the backing plate cannot support the panel stably, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

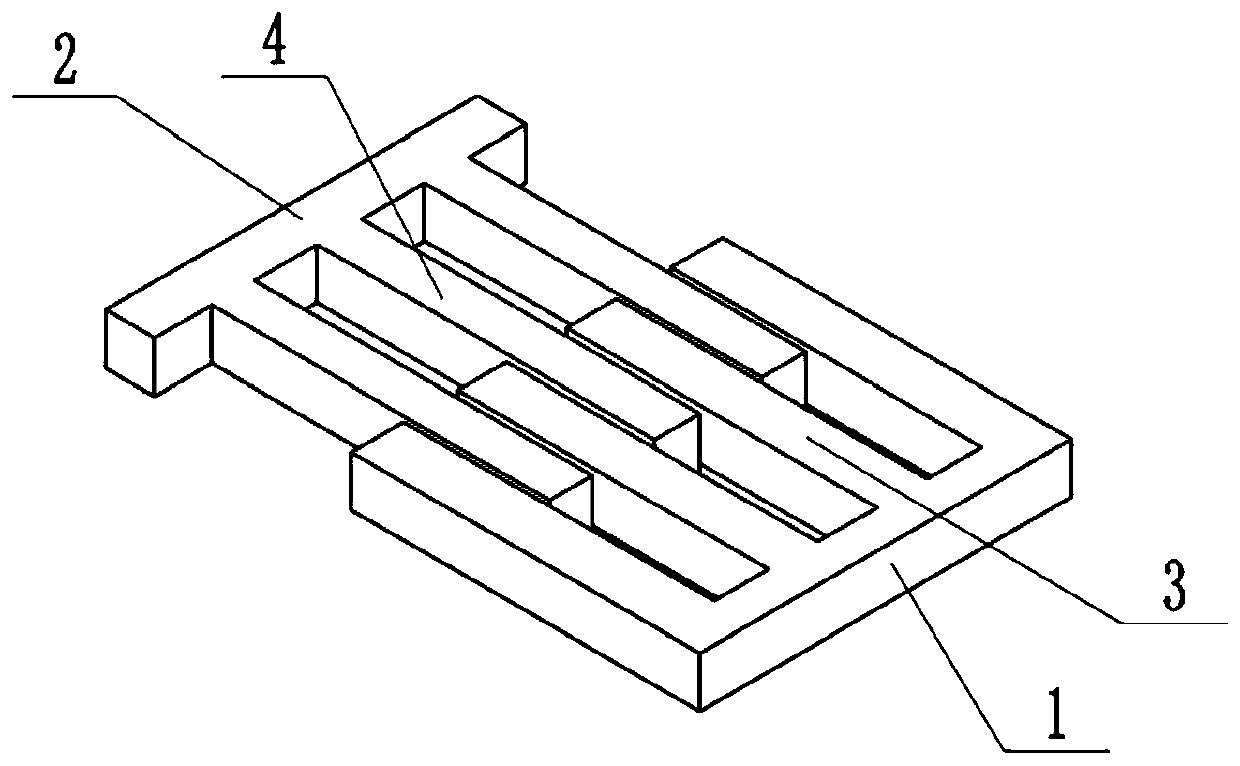

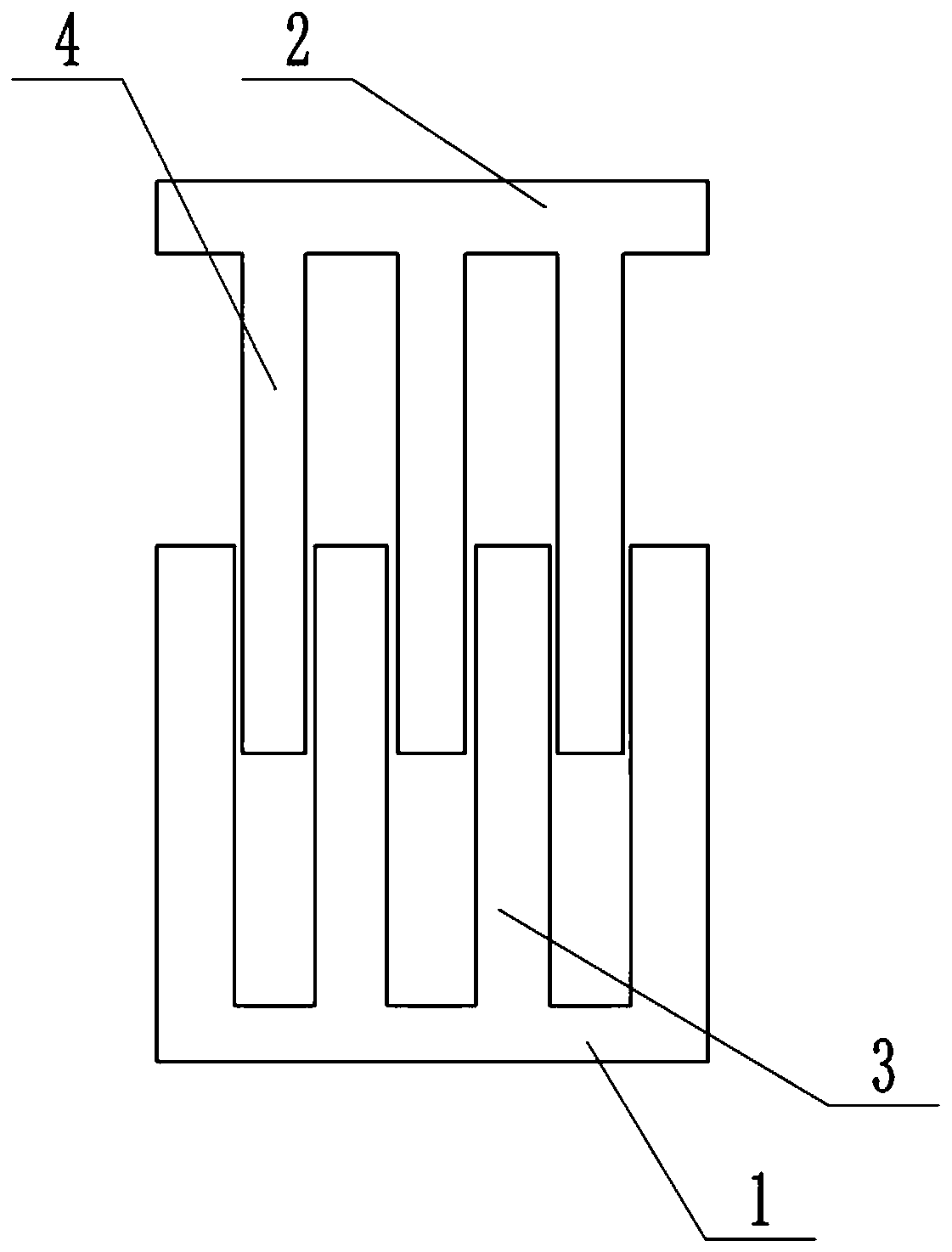

[0029] basically as attached Figure 1-Figure 2 Shown: an adjustable film pad, including a backing plate, the backing plate includes a first backing plate group 1 and a second backing plate group 2, the first backing plate group 1 is provided with a number of first comb teeth 3, this embodiment The number of the first comb teeth 3 is four, there is a first gap between the adjacent first comb teeth 3, and the second backing plate group 2 is provided with a plurality of second comb teeth 4. The number of the second comb teeth 4 is three, there is a second gap between the adjacent second comb teeth 4, the first comb teeth 3 are inserted in the second gap, and the second comb teeth 4 are inserted in the first gap , so that the first backing plate group 1 and the second backing plate group 2 can slide along the length direction of the first comb teeth 3 .

[0030] The specific implementation process is as follows: in this embodiment, the first comb teeth 3 are inserted into the se...

Embodiment 2

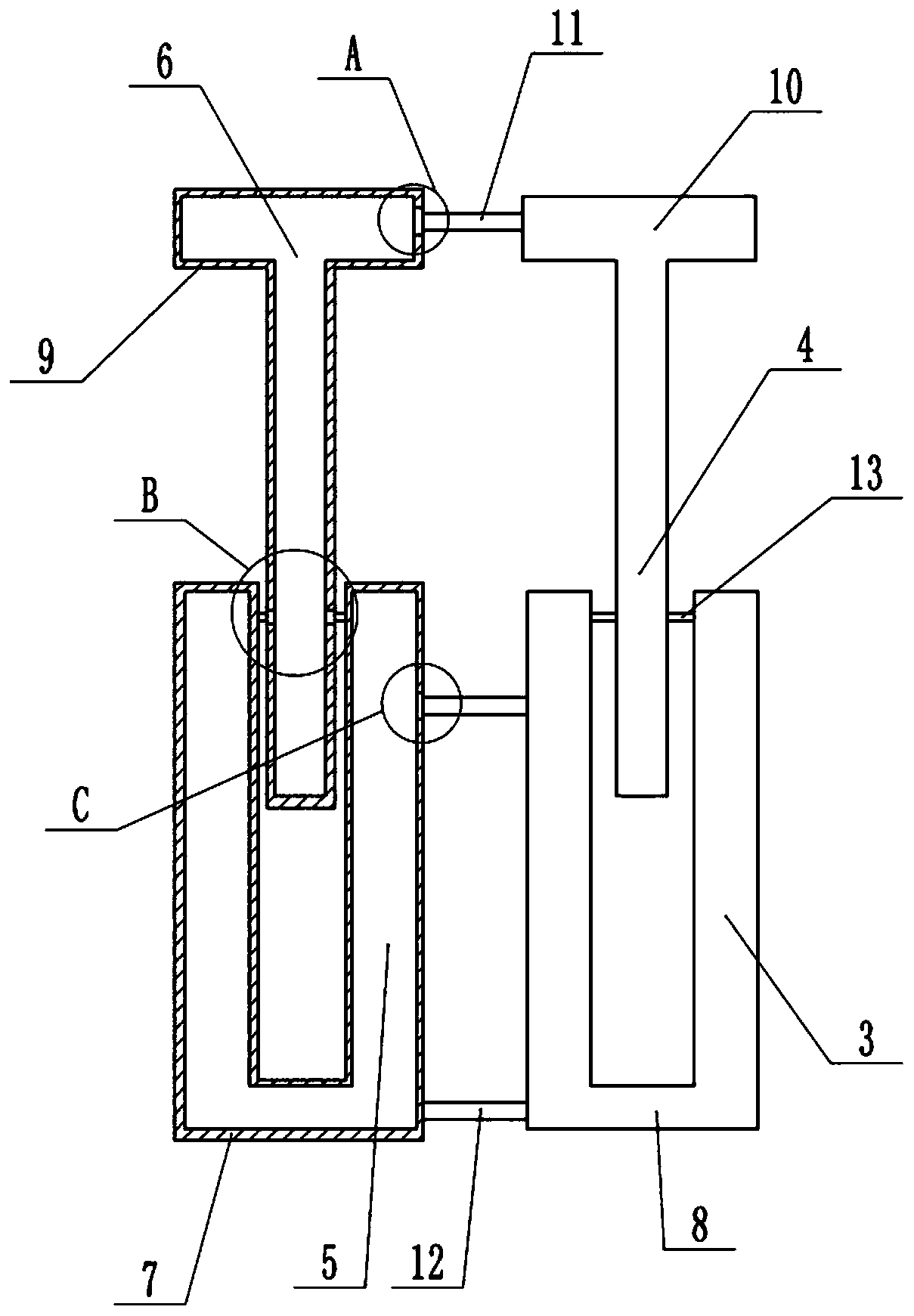

[0032] combine Figure 3-Figure 6 As shown in the figure, the inner walls of both sides of the first gap are provided with sliding grooves arranged along the length direction of the first comb teeth 3, and the side walls of the second comb teeth 4 are welded with sliding rods 13, and the sliding rods 13 are far away from the first comb teeth 4. One end of the second comb teeth 4 is inserted into the chute, so that the sliding rod 13 can slide relatively along the chute, so that through the cooperation of the sliding rod 13 and the chute, the first backing plate group 1 and the second backing plate group 2 The relative sliding between them is relatively smooth.

[0033] The first backing plate group 1 includes a first movable plate 7 and a second movable plate 8. The surface of the first movable plate 7 is provided with a first groove 5 for accommodating the second movable plate 8. The first groove 5 is located in the first movable plate 7. On a comb tooth 3, a first connectin...

Embodiment 3

[0037] combine Figure 7-Figure 9 As shown in the figure, the chute is provided with a number of card slots distributed in sequence along the length of the slot, the end of the sliding rod 13 away from the second comb teeth 4 is stuck in the card grooves, and the sliding rod 13 slides along the width direction of the second comb teeth 4 It is connected to the second comb teeth 4 . Specifically, the side walls of the second comb teeth 4 are provided with holes, and the sliding rods 13 pass through the holes, so that the sliding rods 13 can slide relative to the second comb teeth 4 . The second backing plate group 2 is provided with a control unit for controlling the sliding of the sliding rod 13 . The control unit includes a sliding block 19, a connecting rod 17, a first wedge block 20, a second wedge block 22, a compression spring 18, and a tension spring 21 for pulling the sliding rod 13 away from the slot. The tension spring 21 is connected to the two Between the ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com