High-speed flat plate heat sealing mechanism of hot pack machine

A warm-pack machine and high-speed technology, which is applied in the field of high-speed flat-plate heat-sealing mechanism of warm-pack machines, can solve the problems of rambling, waste of iron powder, unfavorable use of warm-pack machines, etc., and achieves the effect of ensuring aesthetics and improving stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

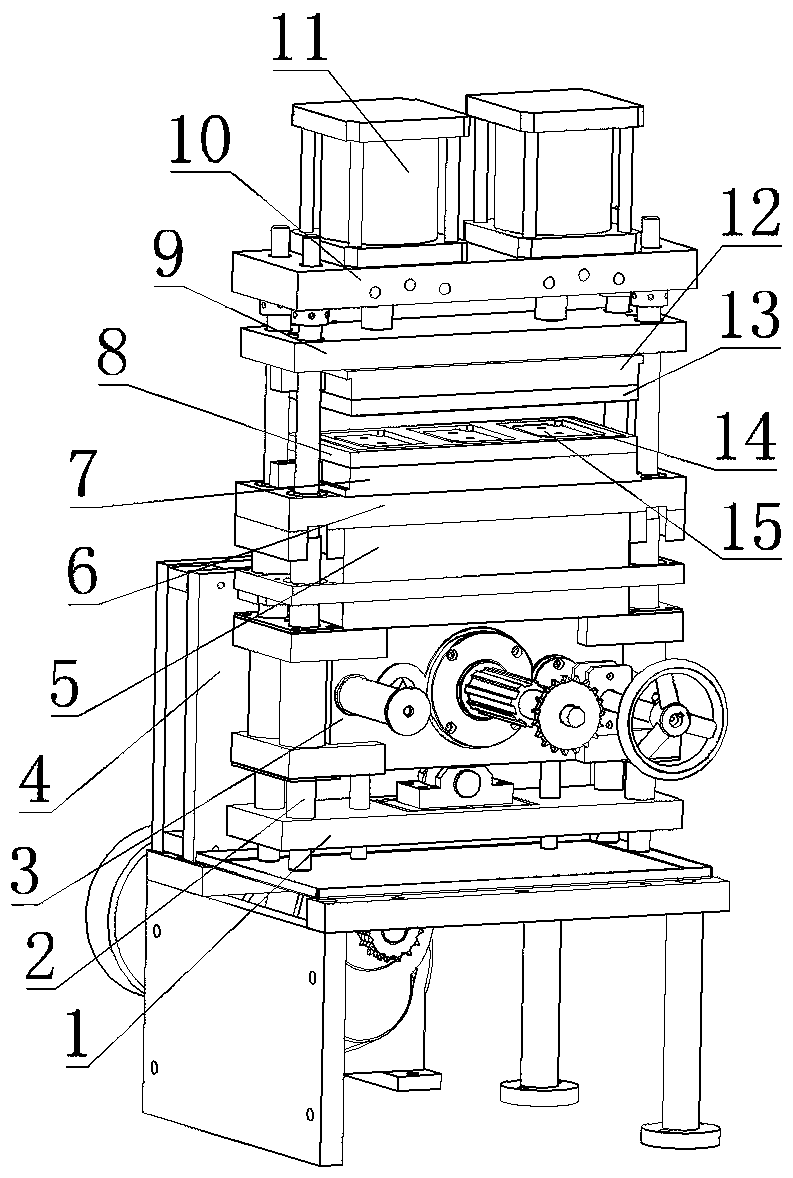

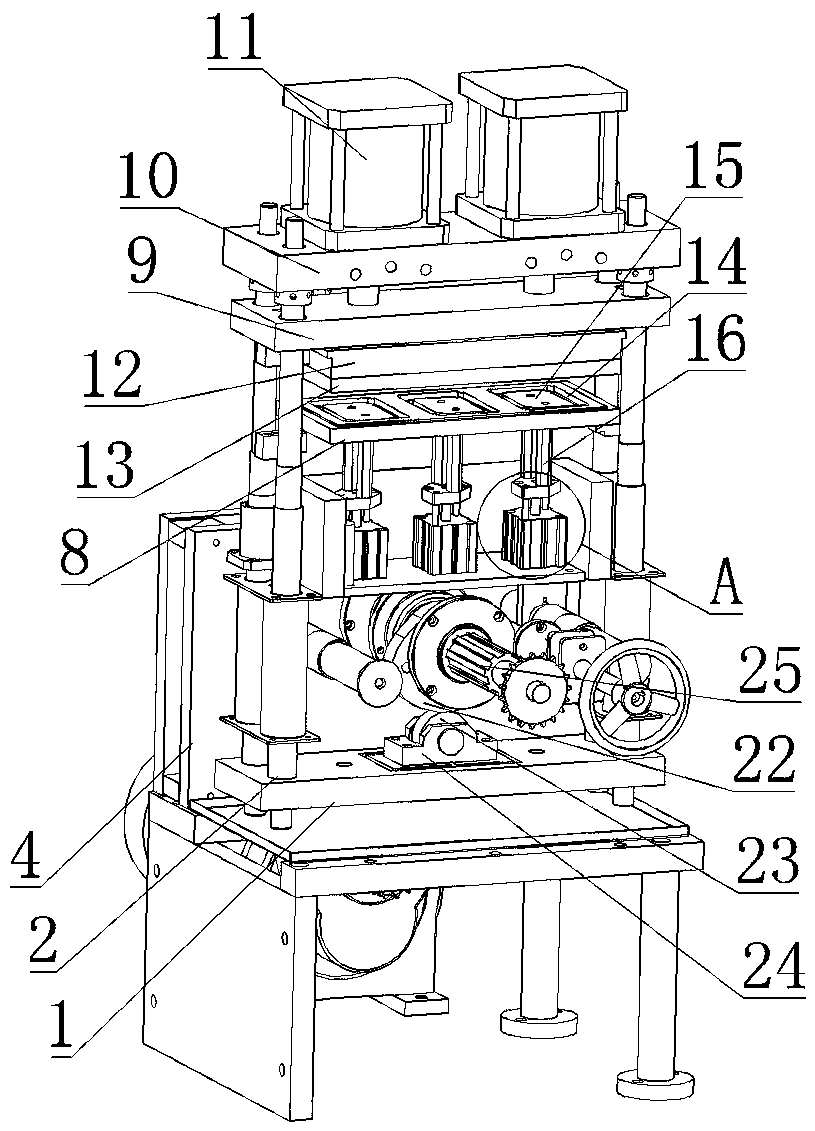

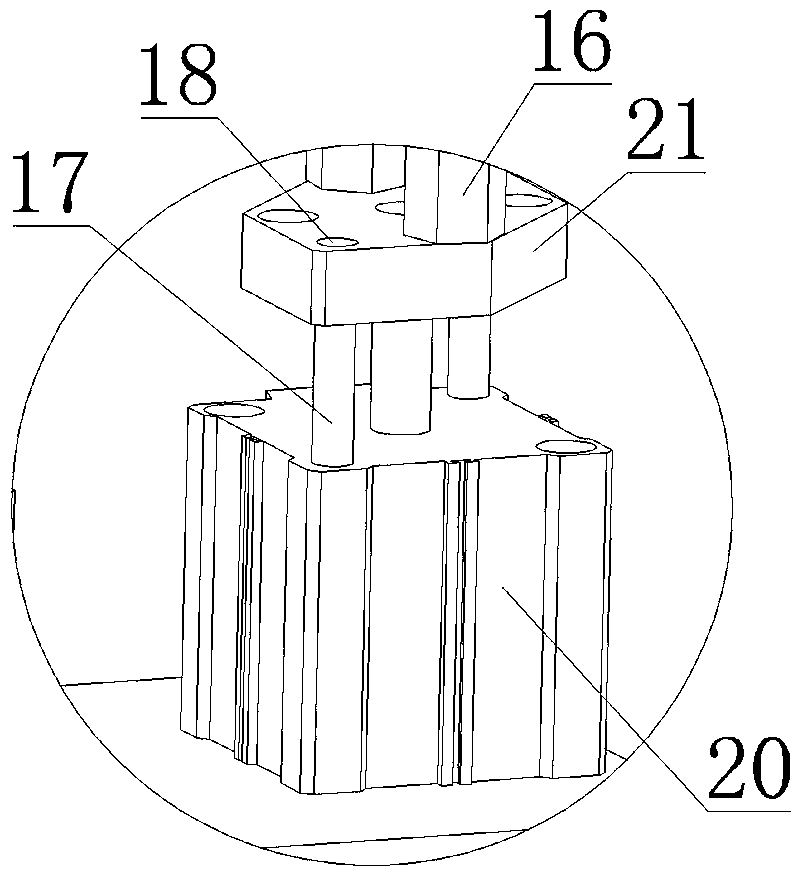

[0018] As shown in the figure, the high-speed flat-plate heat-sealing mechanism of the heating bag machine disclosed by the present invention includes a mounting frame 4, a heat-sealing device and a first lifting device, and the heat-sealing device includes an upper heat-sealing plate 13 and a lower heat-sealing plate 8, and the upper and lower heat-sealing plates The lower heat-sealing plate is connected with the upper heating plate 12 and the lower heating plate 7 respectively, the upper heating plate 12 is connected with the first lifting device, the lower heating plate 7 is installed on the fixed plate 6, and the lower heat-sealing plate 8 and the lower heating plate 7 Corresponding relief grooves 14 are provided, and high magnetic magnets 15 are arranged in the relief grooves 14, and the high magnetic magnets 15 are connected with the second lifting device. In this embodiment, the second lifting device includes a driving cylinder 20, which is arranged in the installation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com