A multi-stage ozone catalytic oxidation internal circulation device and its application method

A technology of ozone catalytic oxidation and internal circulation, applied in chemical instruments and methods, oxidized water/sewage treatment, water treatment parameter control, etc., can solve the problems of low ozone utilization rate and high ozone dosage, and achieve waste water treatment cost saving , increase the contact time, improve the effect of wastewater treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

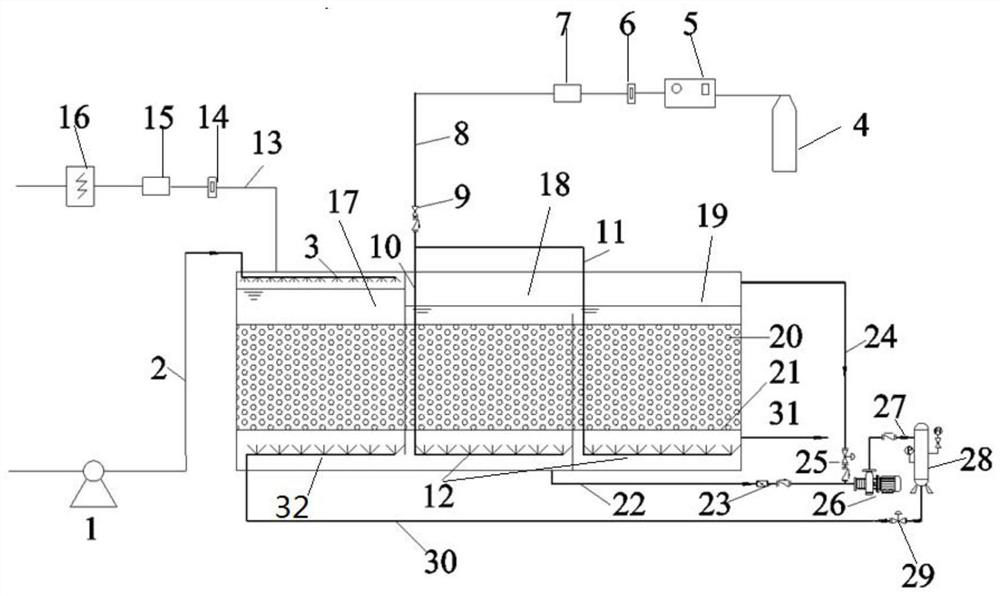

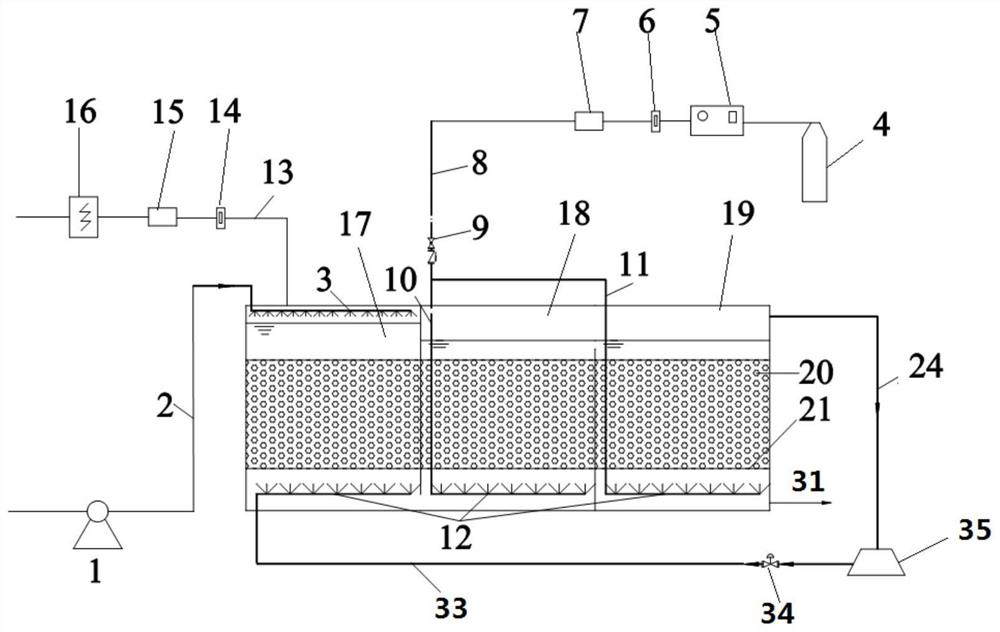

[0022] Embodiment 1: A multi-stage ozone catalytic oxidation internal circulation device in this embodiment includes a water intake system, a main reaction system, an ozone intake system, a tail gas treatment system, an internal circulation system and a water outlet pipe 31;

[0023] The water inlet system includes an inlet pump 1, a water inlet pipe 2 and a water distributor 3. The water outlet of the water inlet pipe 2 is communicated with the water inlet of the water distributor 3. The water distributor 3 is located above the liquid level of the primary reaction tank 17, and the water inlet pipe 2 The water inlet is communicated with the water outlet of the inlet pump 1;

[0024] The main reaction system is divided into a primary reaction pool 17, a secondary reaction pool 18 and a tertiary reaction pool 19 by two baffles; the primary reaction pool 17, the secondary reaction pool 18 and the tertiary reaction pool 19 pass through the two The baffles form vertical baffles; th...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the liquid level of the first-level reaction tank 17 is higher than the liquid level of the second-level reaction tank 18 and the third-level reaction tank 19. The liquid level of the first-stage reaction tank 19 is flat. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the ozone inlet main pipe 8 is provided with an ozone inlet main valve 9 . Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com