A biomass pellet fuel molding machine for new energy

A biomass pellet and pellet molding technology, which is applied in the directions of biofuel, waste fuel, fuel, etc., can solve the problems of drying biomass pellets that cannot be cut, and cleaning of small stones and impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

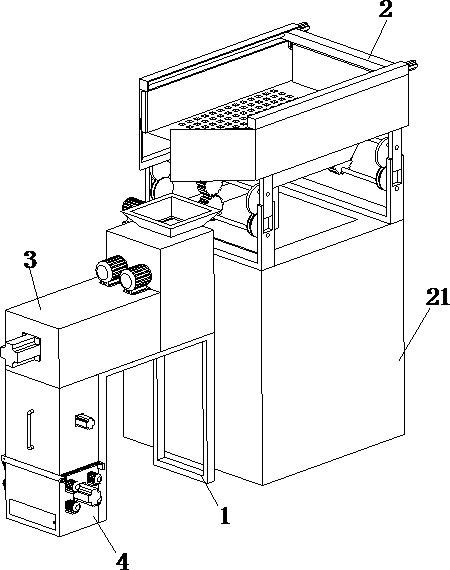

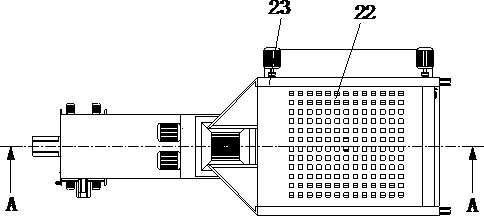

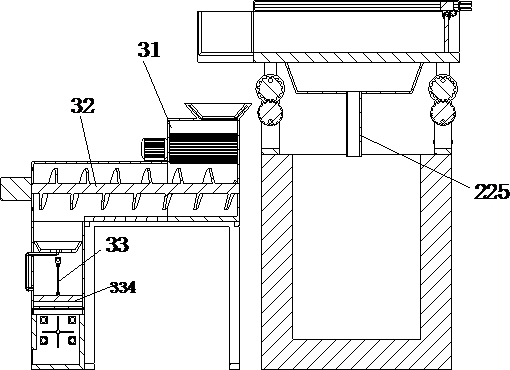

[0028] Attached below Figure 1 to Figure 8 As well as specific implementation methods, the present invention is further described: the embodiment of the present invention provides a biomass pellet fuel molding machine for new energy, including a support frame 1, a material removal assembly 2, a material molding assembly 3, and a particle drying assembly 4 , the support frame 1 is arranged vertically, and the material removal assembly 2 is arranged beside the support frame 1 . The material removal assembly 2 includes a dust collection box 21, a material removal piece 22 and a material moving piece 23, the dust collection box 21 is vertically arranged, and the material removal piece 22 is arranged on the top of the dust collection box 21 , the material moving part 23 is arranged on the top of the material removing part 22 and is slidingly matched with the material removing part 22 .

[0029] The material forming assembly 3 includes a material crushing part 31, a material conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com