Vertical ceramic mold shell and molding method thereof

A technology of ceramic mold shells and molding methods, which is applied in casting molding equipment, molds, cores, etc., can solve problems that affect the quality and qualification rate of finished single crystal blades, single crystal products cannot meet technical requirements, and geometric integrity is extremely sensitive. and other problems, to achieve the effect of reducing technical difficulty, easy molding, preventing fracture and leakage of melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

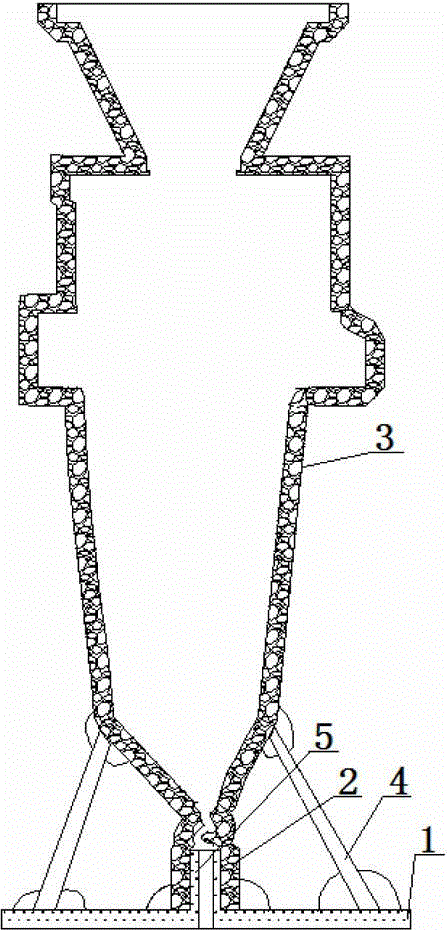

[0040] see figure 1 As shown, a vertical ceramic formwork is used for the pouring of single crystal blades, especially large single crystal blades, in the directional solidification process. The aforementioned ceramic formwork 3 has a blade cavity corresponding to the designed blade shape, and a crystal selector 2 is provided at the bottom of the ceramic formwork 3, and the ceramic formwork 3 and the crystal selector 2 are integrally formed. The aforementioned ceramic formwork 3 is erected above the chassis 1 through the crystal selector 2 at the bottom. Specifically, a raised and hollow connector 5 is provided in the center of the chassis 1. The connector 5 of the chassis 1 and the crystal selector 2 have a The cavities are a joint structure of adhesive combination, that is, the chassis 1 and the ceramic mold shell 3 are a combined structure formed separately. In order to ensure that the ceramic formwork 3 can be erected reliably and stably on the chassis 1, a plurality of s...

Embodiment 2

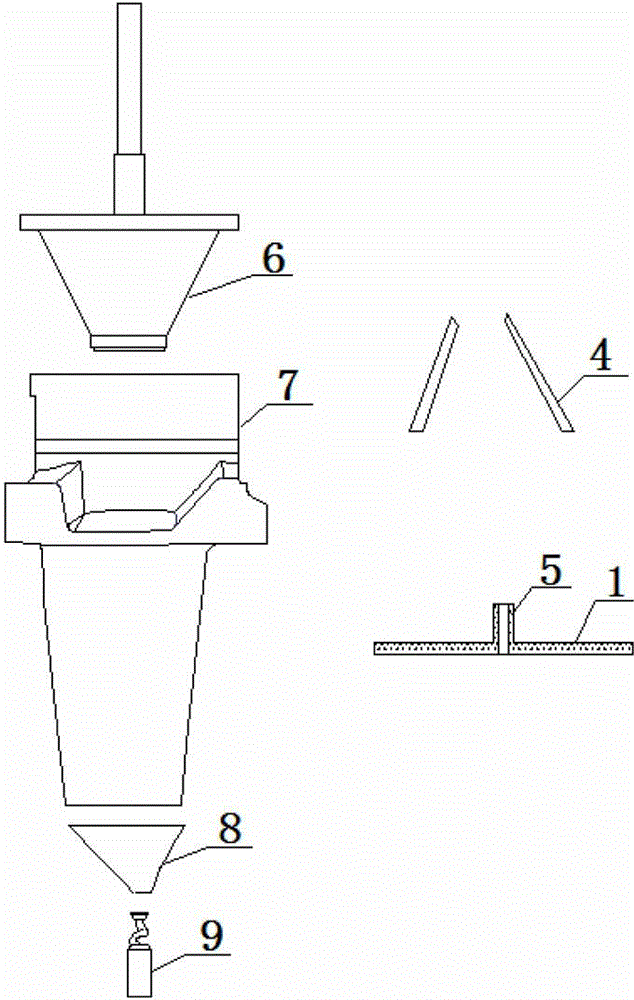

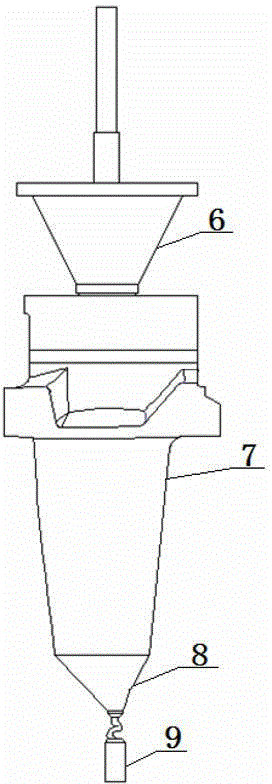

[0049] see Figure 7 As shown, a vertical ceramic formwork is used for the pouring of single crystal blades, especially large single crystal blades, in the directional solidification process. The aforementioned ceramic formwork 3 has a blade cavity corresponding to the designed blade shape, and a crystal selector 2 is provided at the bottom of the ceramic formwork 3, and the ceramic formwork 3 and the crystal selector 2 are integrally formed. The aforementioned ceramic formwork 3 is erected above the chassis 1 through the crystal selector 2 at the bottom. Specifically, a raised and hollow connector 5 is provided in the center of the chassis 1. The connector 5 of the chassis 1 and the crystal selector 2 have a The cavities are a joint structure of adhesive combination, that is, the chassis 1 and the ceramic mold shell 3 are a combined structure formed separately. In order to ensure that the ceramic formwork 3 can be erected reliably and stably on the chassis 1, a plurality of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com