Building wall punching device and using method thereof

A drilling device and a technology for building walls, which are used in work accessories, manufacturing tools, stone processing tools, etc., can solve the problems that the drill bit cannot punch rectangular holes and the operation is cumbersome, so as to facilitate replacement, improve stability, and facilitate The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

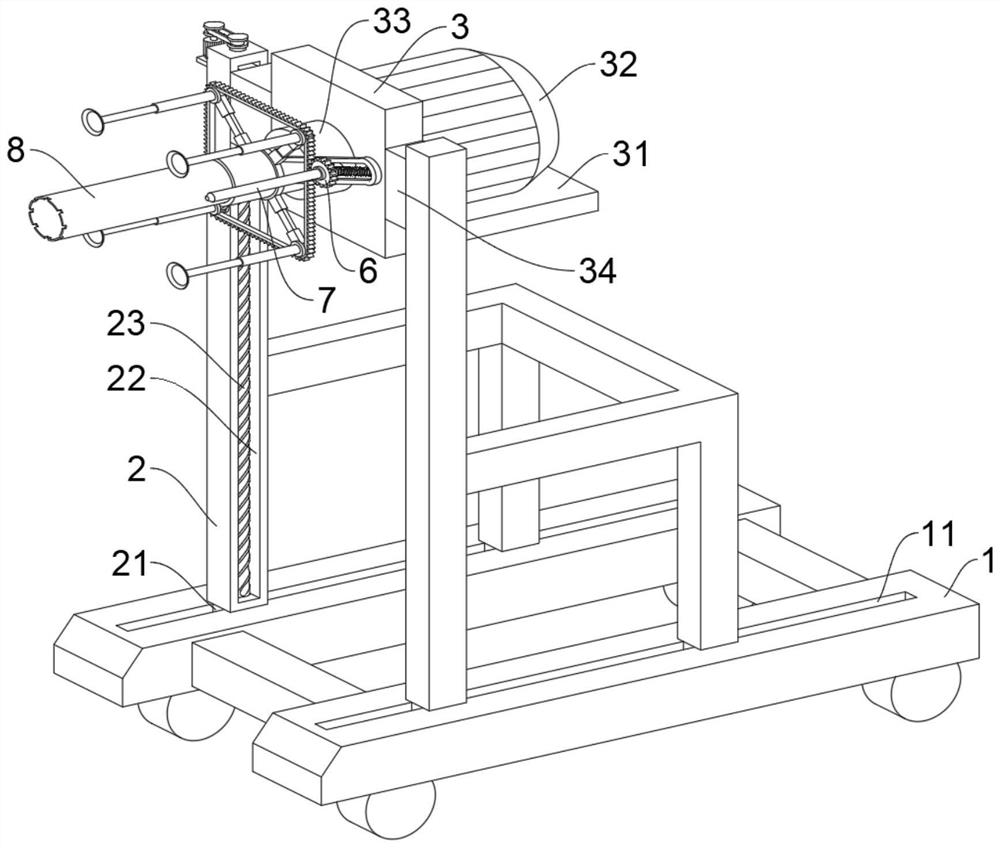

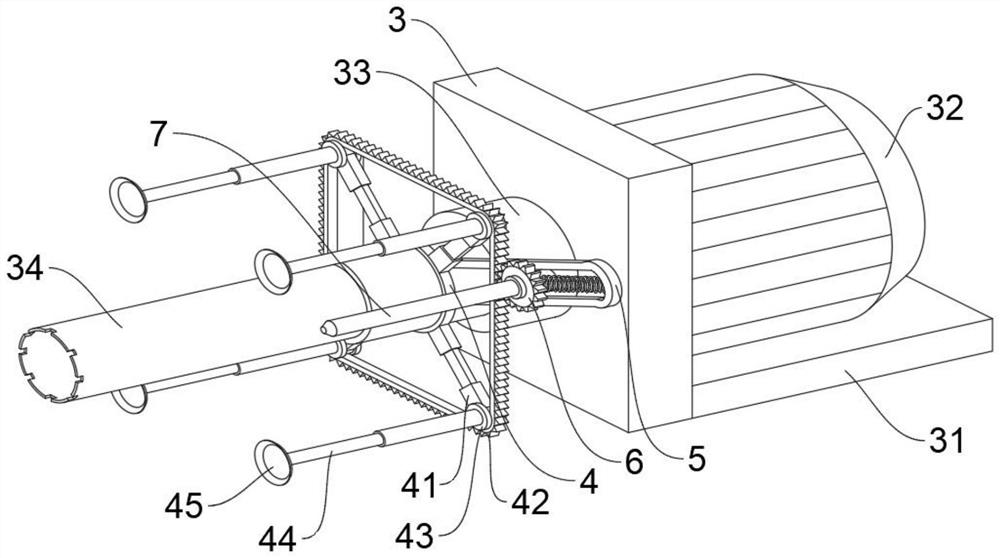

[0035] This embodiment is intended to facilitate solving the problem of how to ensure that the device can drill a rectangular hole at one time, please refer to Figure 1-2, a construction wall punching device, comprising a support frame 3, one end of the support frame 3 is fixedly installed with a support plate 31, a servo motor 32 is fixedly installed on the support plate 31, and the output end of the servo motor 32 is connected to the support frame 3 through interpenetration , and is connected with a connecting shaft 33, one end of the connecting shaft 33 is installed with a first drill bit 8, both ends of the outer wall of the support frame 3 are fixedly installed with a first slider 34, and both ends of the support frame 3 are also installed with vertical rods 2, vertical The inner side wall of the rod 2 is provided with a first chute 22, the first chute 22 is connected with a screw rod 23, the screw rod 23 is threadedly connected with the first slider 34, and the lower end...

Embodiment 2

[0044] This embodiment is intended to facilitate solving the problem of how to stabilize the gear 6 and the second drill bit 7. This embodiment is an improvement made on the basis of Embodiment 1. For details, please refer to figure 1 , figure 2 and Figure 5 The sliding block 53 is sleeved with a collar piece 52 , a spring 51 is fixedly installed on the outer wall of the collar piece 52 , and one end of the spring 51 away from the collar piece 52 is fixedly connected to the inner wall of the sliding rod 5 .

[0045] The diameters of each edge of the chain rack 42 from the connecting shaft 33 are different. The gear 6 rotates along the chain rack 42 and slides on the sliding rod 5. During the sliding process, the spring 51 can expand and contract. Under the action of the spring 51 , which can ensure that the gear 6 can always adhere to the side wall of the chain-shaped rack 42 for rotation and autorotation, so as to improve the stability of the second drill bit 7 .

[0046]...

Embodiment 3

[0050] This embodiment is intended to facilitate solving the problem of how to drill rectangular holes of different sizes. This embodiment is an improvement made on the basis of Embodiment 2. For details, please refer to Figure 1-4 The support rod 41 is also provided with a cavity 411, an electric lifting rod 412 is installed in the cavity 411, an inner rod 413 is fixedly installed at one end of the electric lifting rod 412, and one end of the inner rod 413 is slidably connected with the chain rack 42.

[0051] Open the electric lift rod 412 to make it extend, the distance between the inner rods 413 can be increased, and it is convenient to install the chain rack 42 with a larger diameter, so the rectangle drilled by the second drill bit 7 can be enlarged.

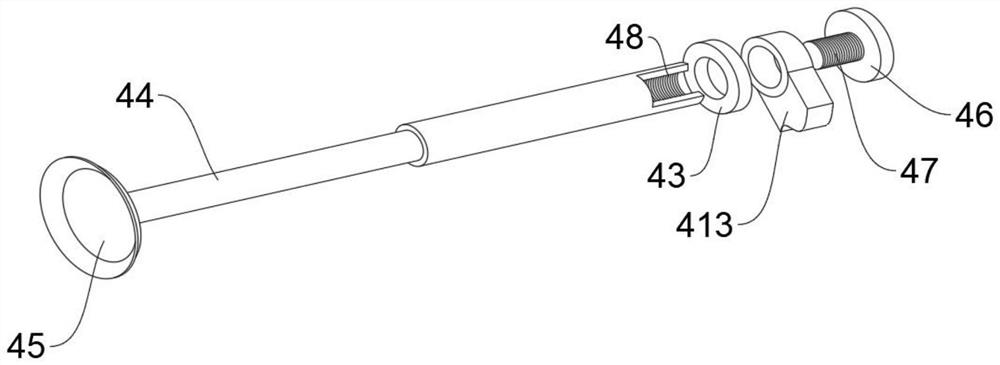

[0052] An end of the inner rod 413 away from the electric lift rod 412 is inserted with a squeeze rod 44 , one end of the squeeze rod 44 is fixedly installed with a suction cup 45 , and the upper middle of the squeeze rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com