Shifting fork abrasion prevention device of electrically-controlled electrodynamic type machine automatic transmission and gear shifting method

An automatic transmission, electronically controlled electric technology, applied in mechanical control devices, transmission control, mechanical equipment, etc., can solve the problems of affecting reliability, fork wear, and insignificant effect, so as to prevent wear and avoid shifting forks. Wear and disengagement prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

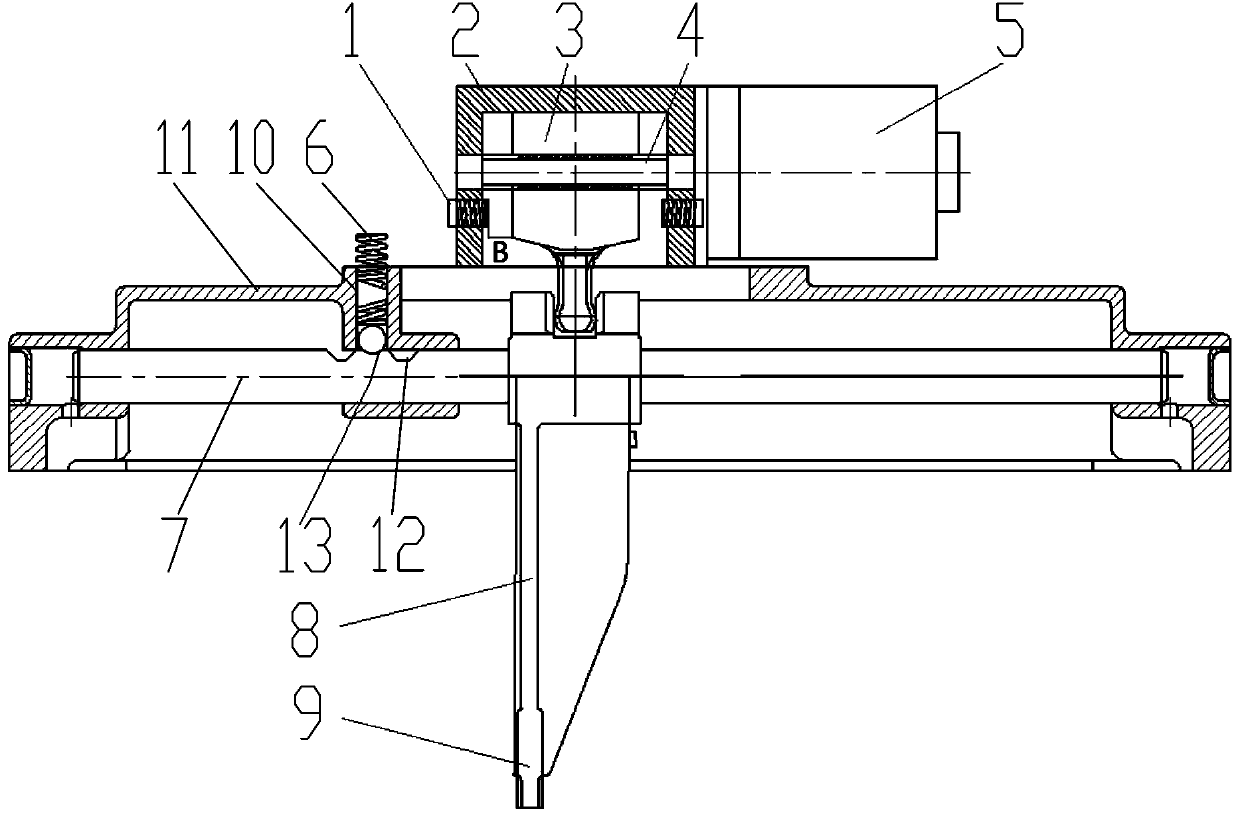

[0032] see Figure 1-2 , an electronically controlled electric mechanical automatic transmission to prevent shifting fork from wear and tear, it includes a support 2, the inside of the support 2 is supported by a bearing seat to install a ball screw reduction mechanism 4, and the ball screw reduction mechanism 4 and the pulling head 3 form a screw transmission cooperation, and the ball screw reduction mechanism 4 is connected with the output shaft of the shift motor 5, and the shift motor 5 is fixedly installed on the outer wall of the support 2; the pulling head The other end of 3 is in contact with the slot at the top of the fork 8, the fork 8 is fixedly mounted on the fork shaft 7, and the two ends of the fork shaft 7 are slidably mounted on the fork shaft frame 11, A gear calibration mechanism is arranged between the fork shaft frame 11 and the fork shaft 7 , and a sliding block 9 is installed at the end of the fork 8 . By adopting the device with the above structure, it ...

Embodiment 2

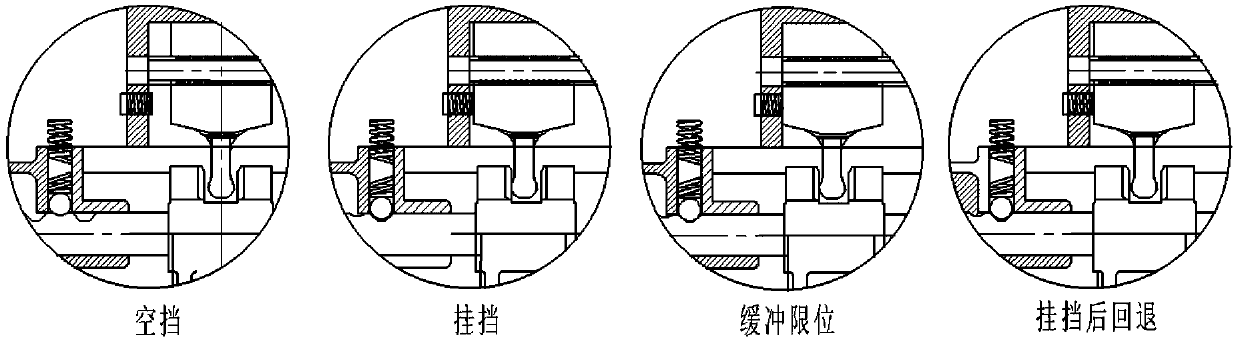

[0040] The gear shifting method of the anti-wear device of the electronically controlled electric mechanical automatic transmission:

[0041] Step1: Determine the press-in distance a of the elastic pin 1 according to the processing accuracy of the transmission shift mechanism, the reserved clearance of each part, and the deformation amount during shifting, and then adjust the pre-tightening force of the elastic pin 1;

[0042] Step2: Adjust the fork shaft 7, pull head 3 and elastic pin 1 to ensure that in the neutral position, the sum of the distance B from the two ends of the pull head 3 to the elastic pin and the press-in distance a of the elastic pin is equal to the effective shift stroke;

[0043] Step3: During calibration, the toggle head 3 moves to the position where it is in contact with the elastic pin 1 but not compressed, as the "ideal position to stop";

[0044] Step4: During the gear shifting process, the shifting force adaptive method is used to engage gears;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com