Pre-burying device for gas inlet pipe sleeve in indoor shear wall and pre-burying method thereof

A pre-embedded device and shear wall technology, applied in the direction of pipes/pipe joints/fittings, walls, pipes, etc., can solve the problems of a large amount of manpower and easy bending of gas pipes, so as to reduce labor, reduce the risk of cracks, The effect of improving the efficiency of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

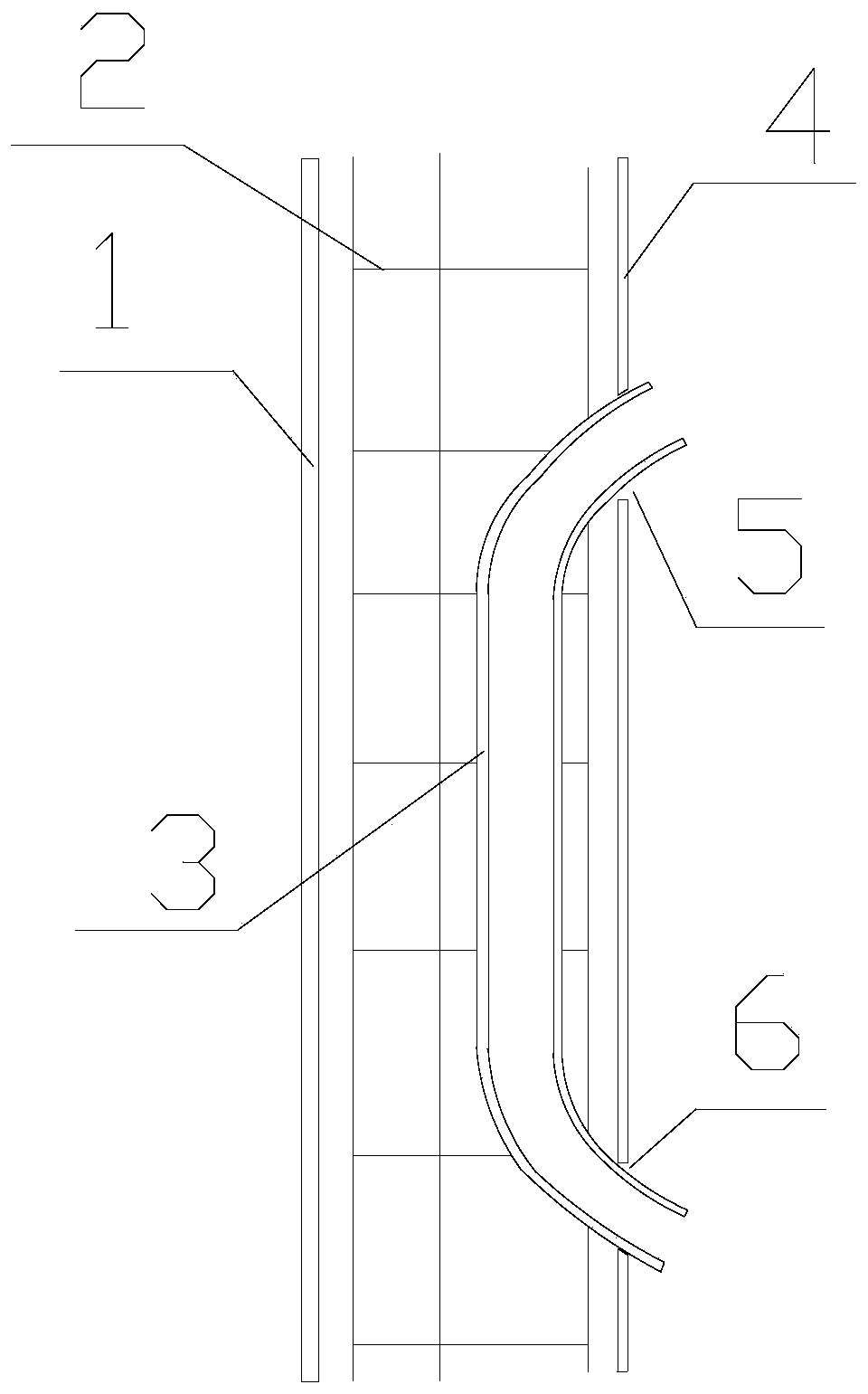

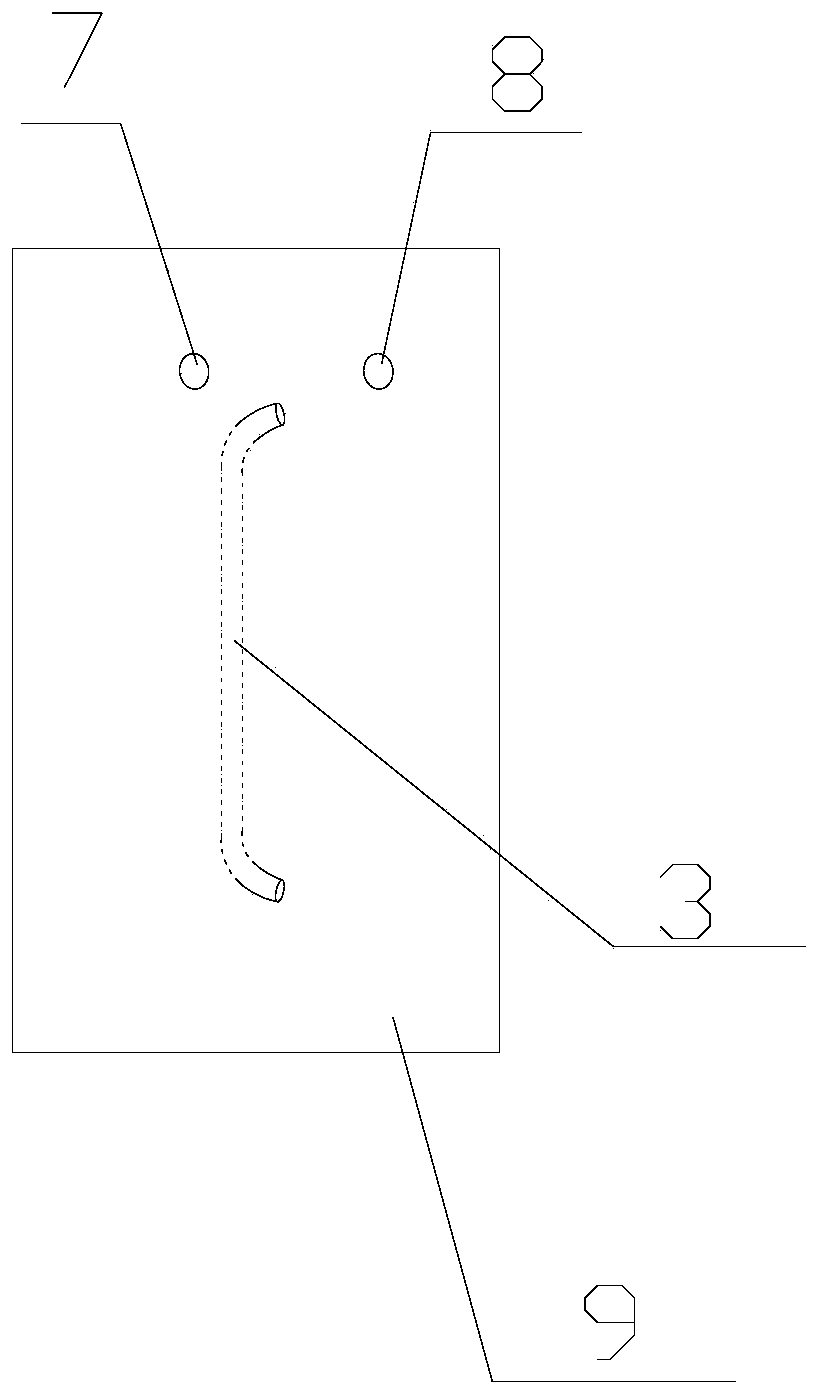

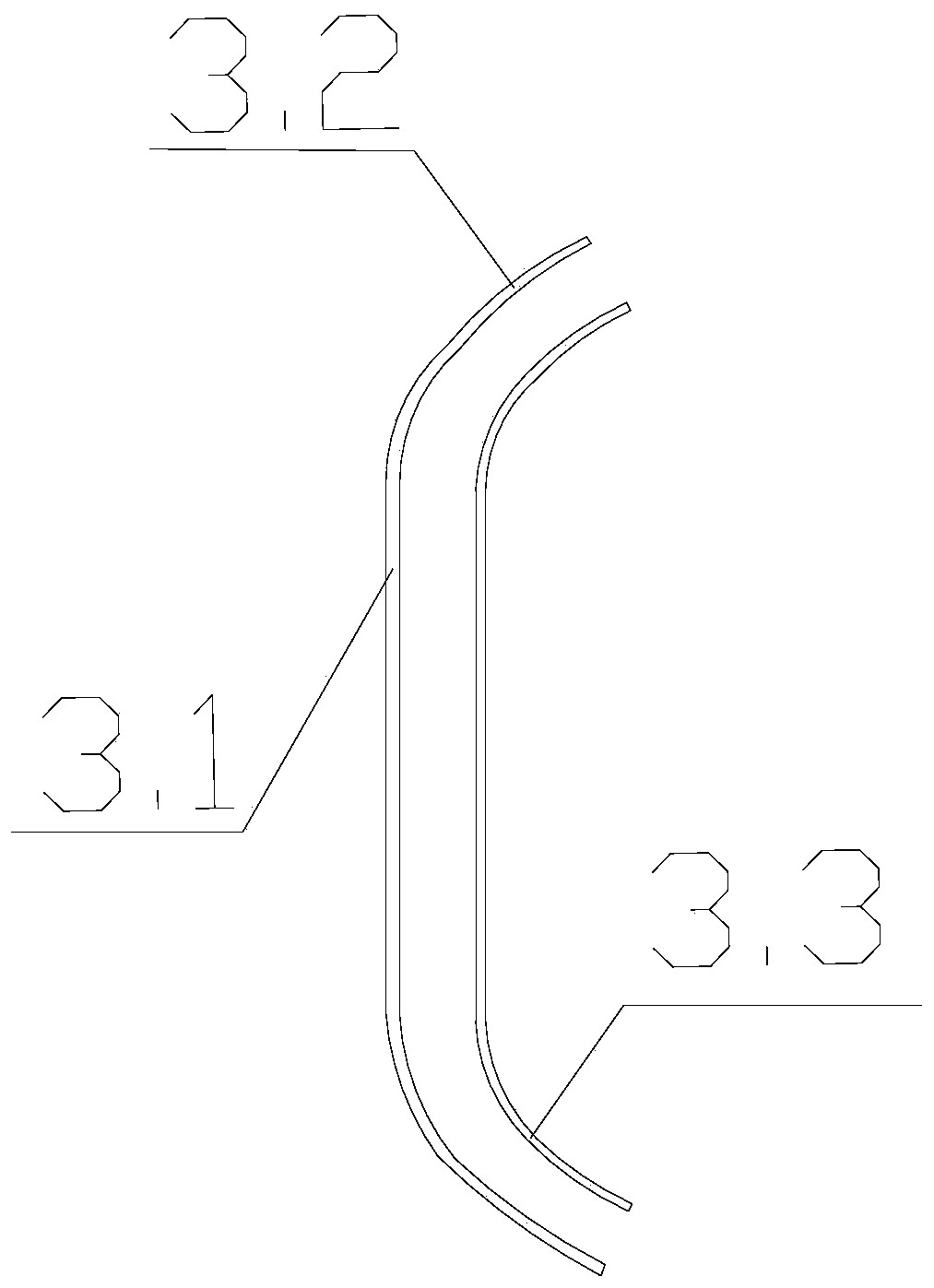

[0025] like figure 1 As shown, a pre-embedded device for gas inlet pipe casing in an indoor shear wall according to the present invention includes an outer formwork 1 , a steel frame 2 , a gas pipe casing 3 and an inner formwork 4 . The outer formwork 1 and the inner formwork 4 are arranged on both sides of the reinforcement skeleton 2 . The gas pipe casing 3 is embedded in the reinforcement frame 2, and the two ends pass through the inner formwork 4 and protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com