Efficient vacuum condenser

A condenser and vacuum technology, which is applied in the field of high-efficiency vacuum condensers, can solve the problems of heat exchange efficiency limitation and inability to achieve optimal results, and achieve the effects of energy saving, sufficient heat exchange and high heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0028] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with examples of implementation and accompanying drawings. The present invention can be implemented in the following ways:

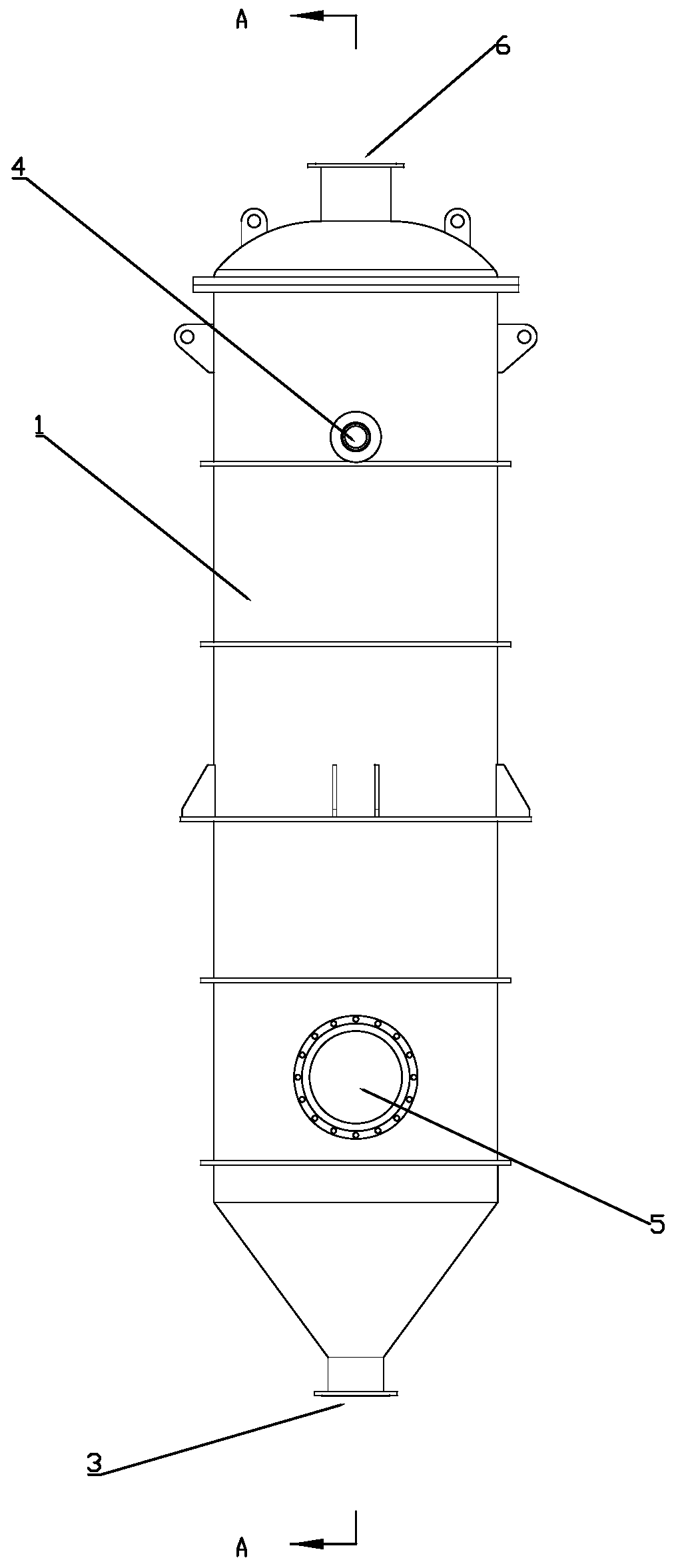

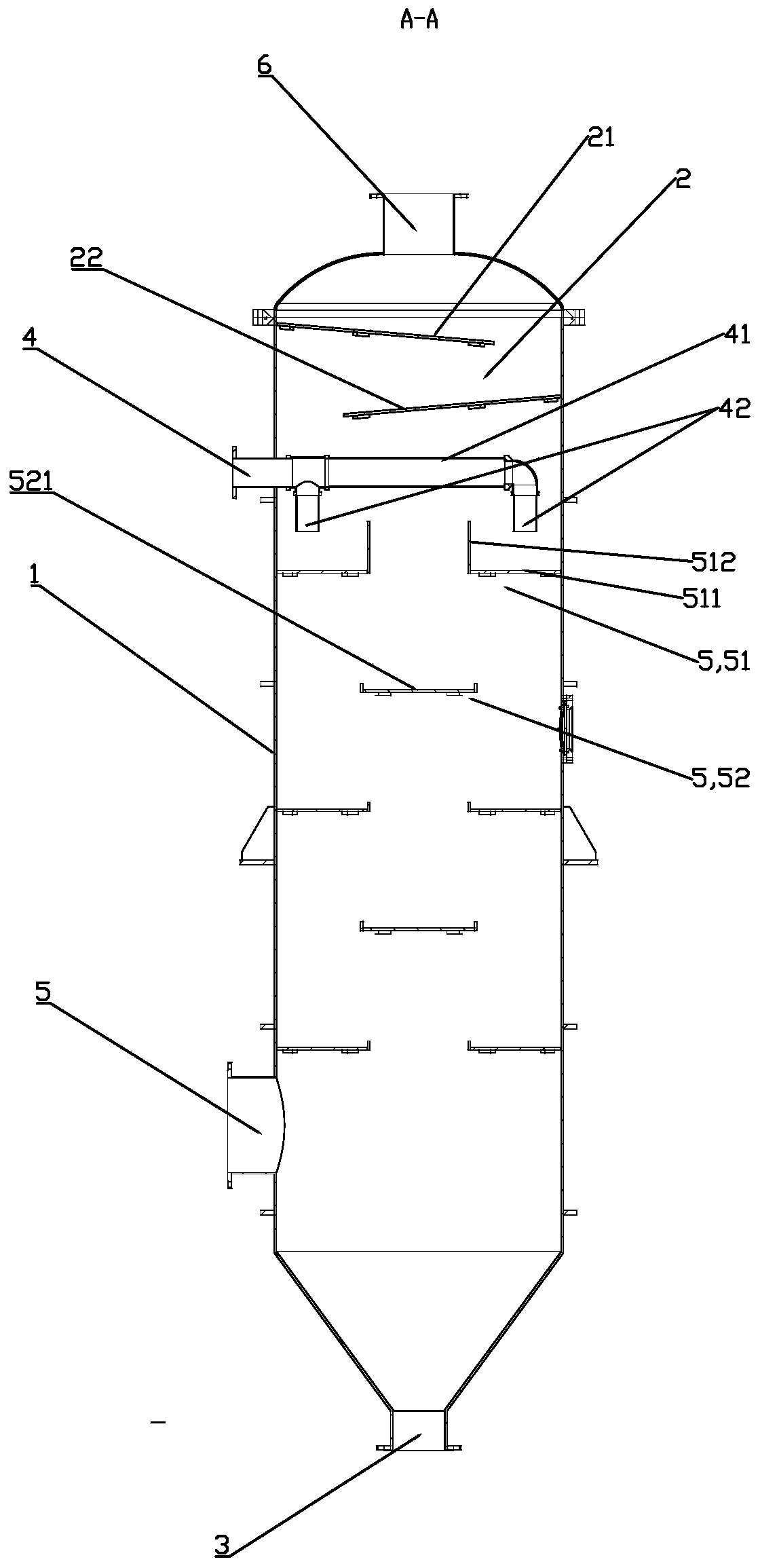

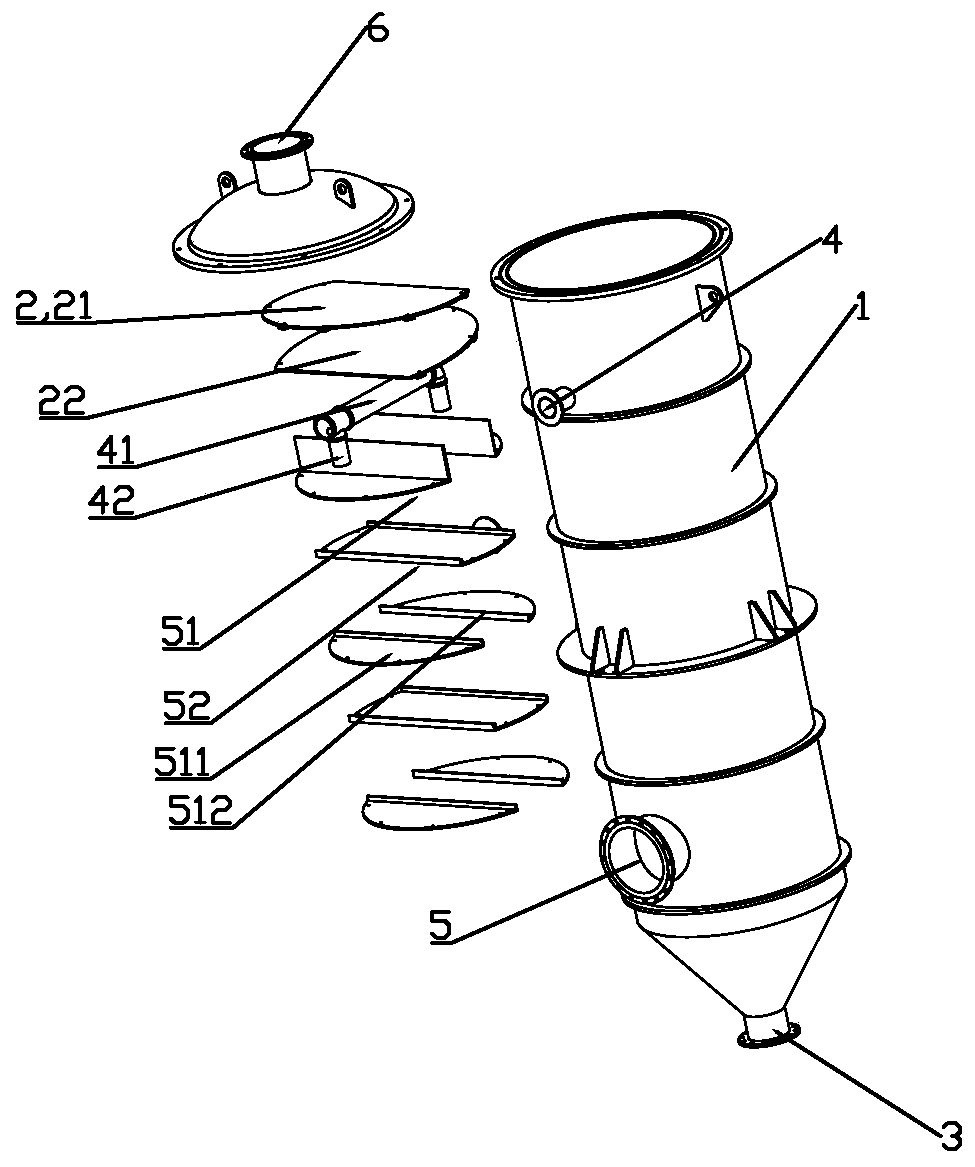

[0029] As shown in the figure, the high-efficiency vacuum condenser includes a tank body 1, and a vacuum port 6 connected with a vacuum tube is arranged on the upper part of the tank body 1, and the vacuum tube of the vacuum pump is connected to the vacuum port 6. In addition, the vertical height between the position where the vacuum pump is placed and the vacuum port 6 is generally more than 12 meters. The bottom of the tank body 1 is provided with a drainage recovery port 3 docked with the drainpipe, and the height of the drainage recovery port 3 and the ground is generally more than 10.5 m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap