Aircraft assembly line operation scheduling method based on genetic variable neighborhood algorithm

A job scheduling and assembly line technology, applied in genetic rules, constraint-based CAD, computing, etc., can solve problems such as inability to proceed simultaneously, increase problem space and computational complexity, achieve narrow solution space, improve local search capabilities, The effect of improving the quality of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

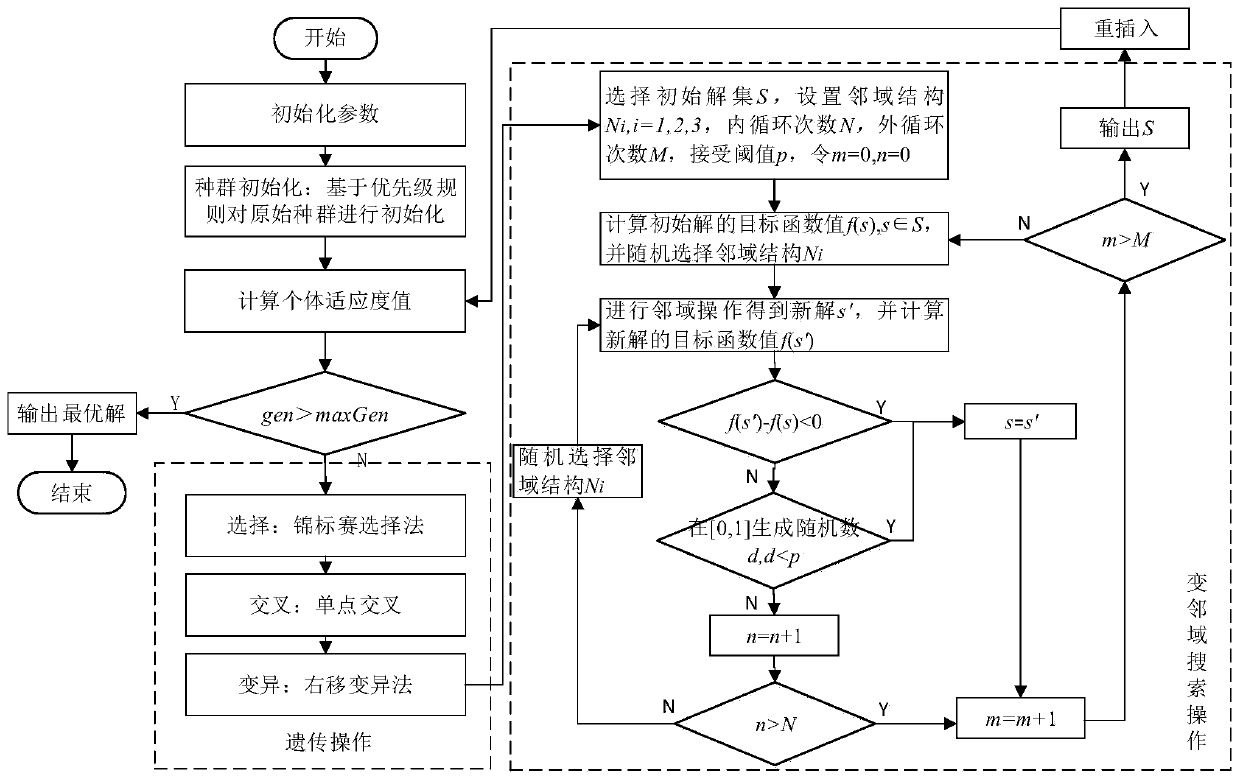

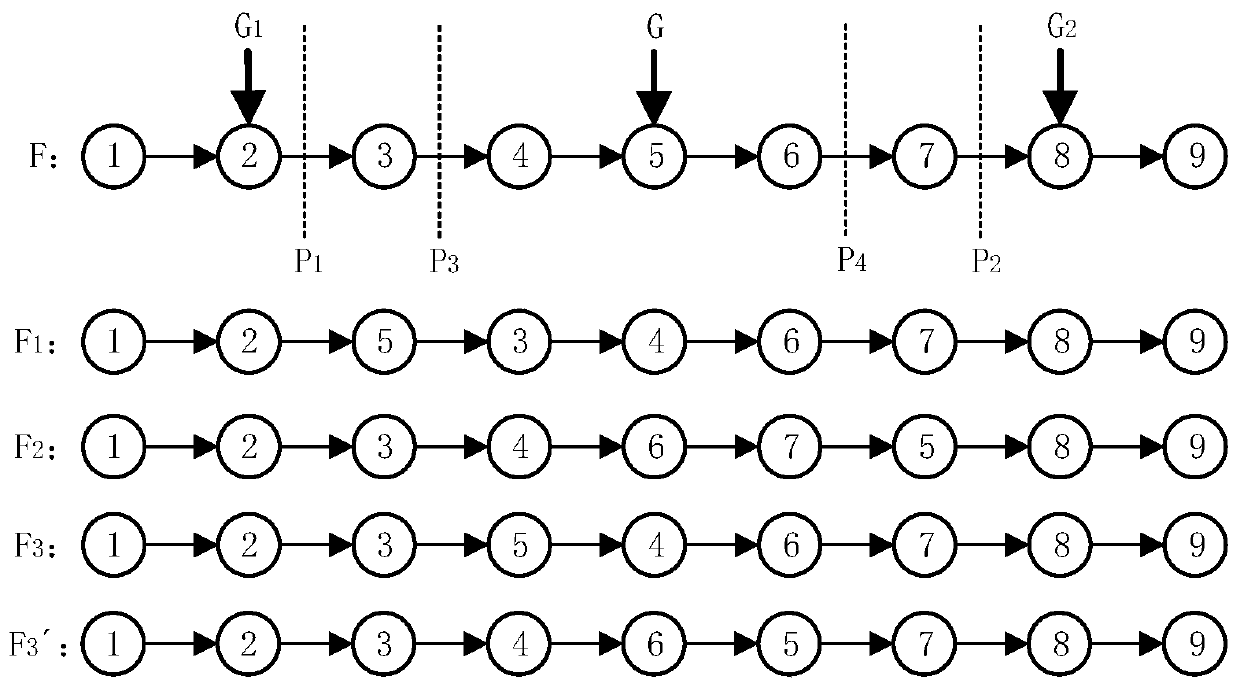

Method used

Image

Examples

Embodiment Construction

[0040] Using the calculation examples in the standard calculation example library PSPLIB, 5 sets of initial input data are randomly selected under the three working conditions with the number of activities being 30, 60 and 90. Operation items of each scale share 4 kinds of resources, each resource has a maximum supply per unit time, and each activity requires one or more resources. Randomly select a resource as the space requirement, randomly generate the number of sections [1, z] for each working condition, and randomly assign activities to each section, the maximum space capacity of a section N m It is a random integer between the maximum value of space demand in the activities executed in this section and the maximum supply per unit time of resources as space demand. Numerical experiments were carried out on the Matlab2014b platform, and IGA-VNS was compared with traditional genetic algorithm (GA), variable neighborhood algorithm (VNS) and genetic simulated annealing algori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com