Method for Predicting the Vibration Characteristics of Composite Soft Sandwich Structures Containing Cavities in Fluid

A technology for composite materials and structural vibration, applied in computer materials science, instrumentation, design optimization/simulation, etc., can solve problems such as a large number of meshes, unfavorable characteristics research, large errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

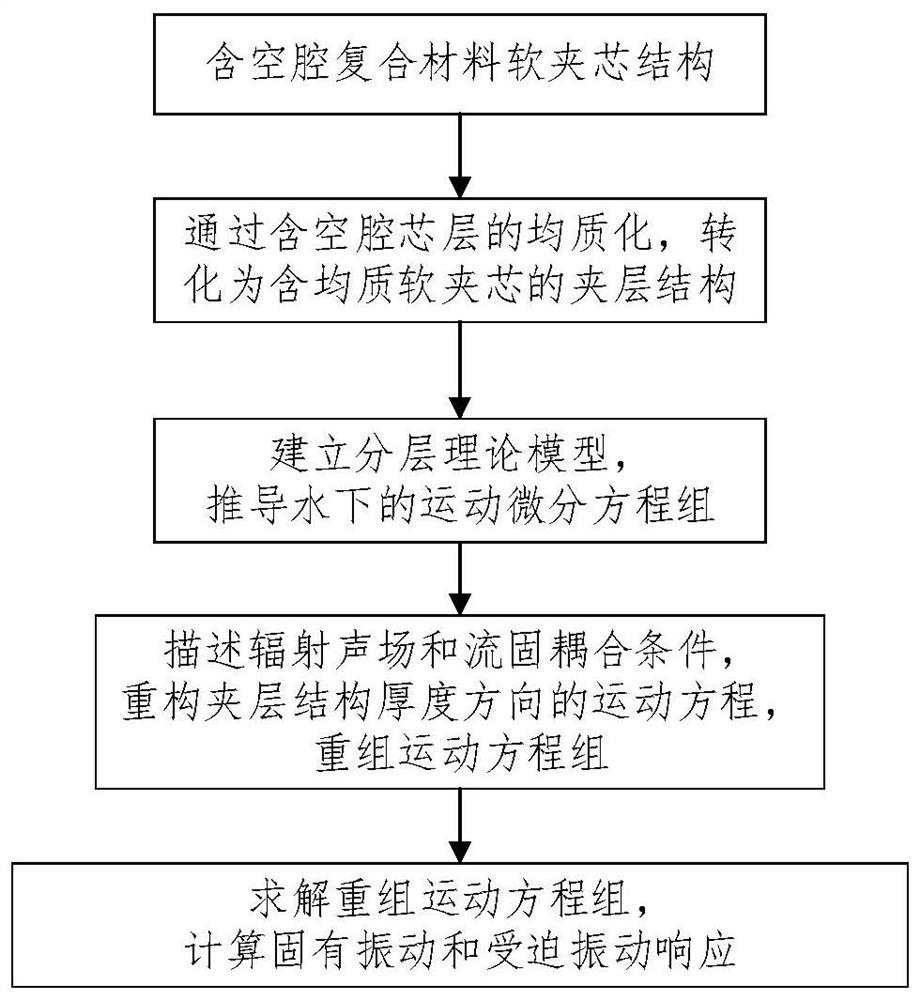

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

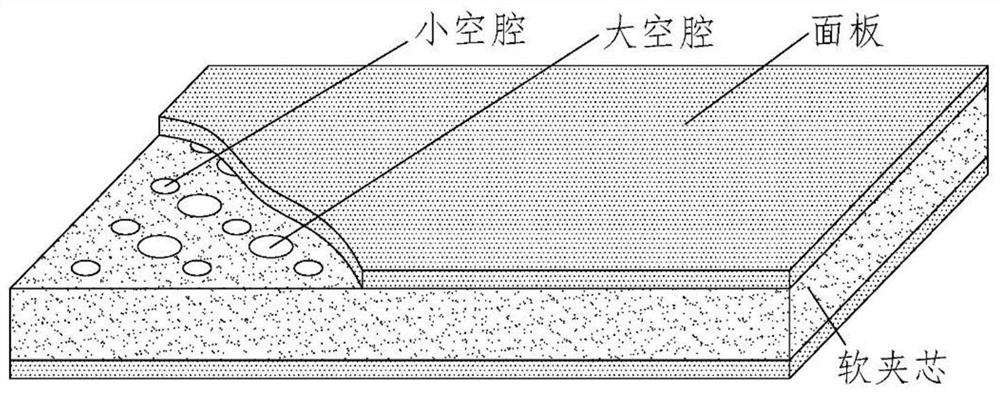

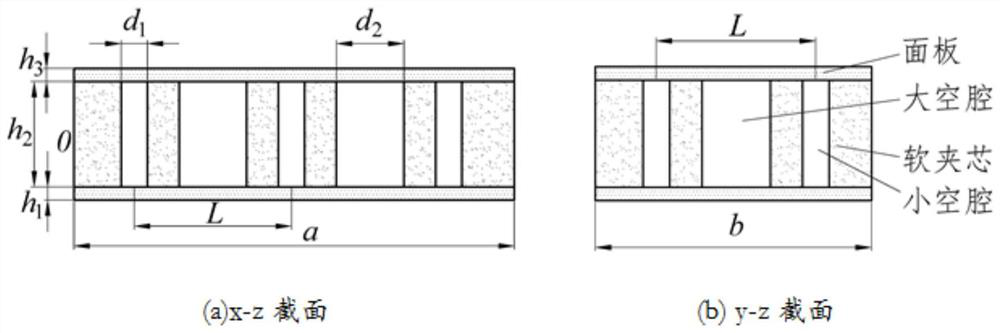

[0075] Such as figure 2 and image 3 As shown, the cavity-containing composite material soft sandwich structure in this embodiment contains two kinds of periodic cavities, wherein the thickness of the upper panel and the lower panel are the same, so they are both called panels, and the cavity-containing composite material soft sandwich structure The length along the x direction is d, the length along the y direction is b, and the sandwich structure in the middle is made of soft material.

[0076] Step 1: Homogenization of the core layer containing two periodic cavities.

[0077] The core layer containing two kinds of periodic cavities was decomposed into a core layer containing small cavities and a large cavity.

[0078] (1) First, homogenize the core layer containing small cavities, take the core material as the matrix phase, and the small cavities as the inclusion phase, and obtain orthotropic material A equivalently, using the Mori–Tanaka method, its equivalent elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com