Carrier recovery apparatus of liquid electrophotographic printer

A carrier recovery and printer technology, which is applied to the equipment of the electric recording process using the charge pattern, the electric recording process using the charge pattern, and the electric recording technique, etc., and can solve the problems of the decrease of the filtering ability and the outflow of the gas carrier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

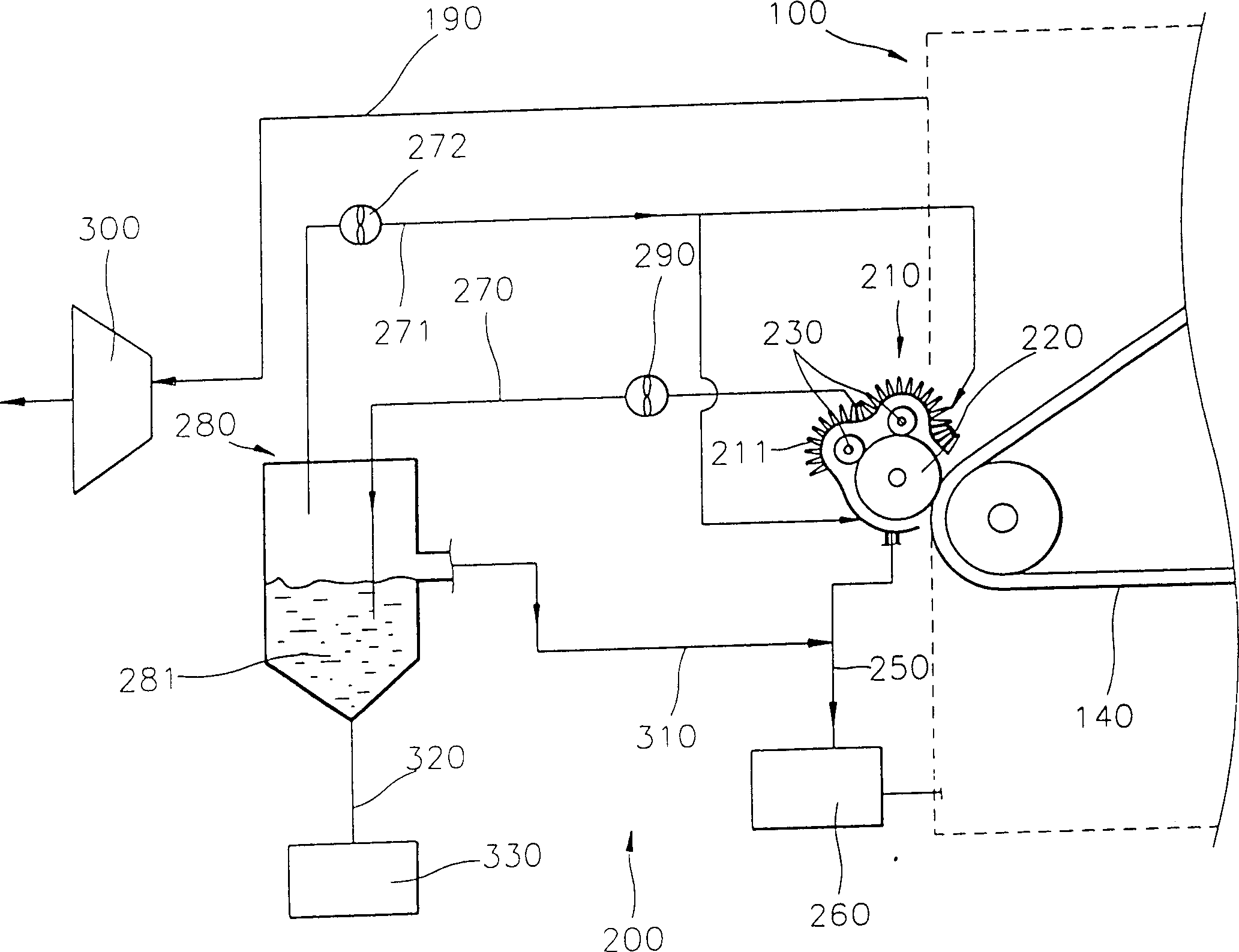

[0016] image 3 The carrier recovery apparatus of the wet electrophotographic printer of the present invention shown in includes a drying roller 220 for absorbing a liquid carrier from a photosensitive belt 140, a heating roller that contacts and heats the drying roller 220 and evaporates the absorbed liquid carrier. 230 , both the drying roller and the heating roller are rotatably installed in the recovery cavity 210 .

[0017] Since a plurality of heat exchange fins 211 are formed on the outer surface of the recovery chamber 210, some evaporated gas carriers can be deposited on the inner surface of the recovery chamber 210 by heat exchange with the surrounding air passing through the plurality of heat exchange fins 211. cool down. The cooling carrier collected from the inner surface of the recovery cavity 210 is then introduced into the cartridge 260 through the first recovery pipe 250 .

[0018] The recovery chamber 210 communicates with a cooler 280 through a supply line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com