Graphene clad micro-pore silkworm excrement and ulfur composite positive electrode material and preparation method

A composite cathode material, graphene coating technology, applied in the field of material chemistry and electrochemistry, can solve the problems of poor cycle performance, uneven sulfur loading, weak adsorption force of composite materials, achieve high rate performance, avoid pore blockage linearity , Improve the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

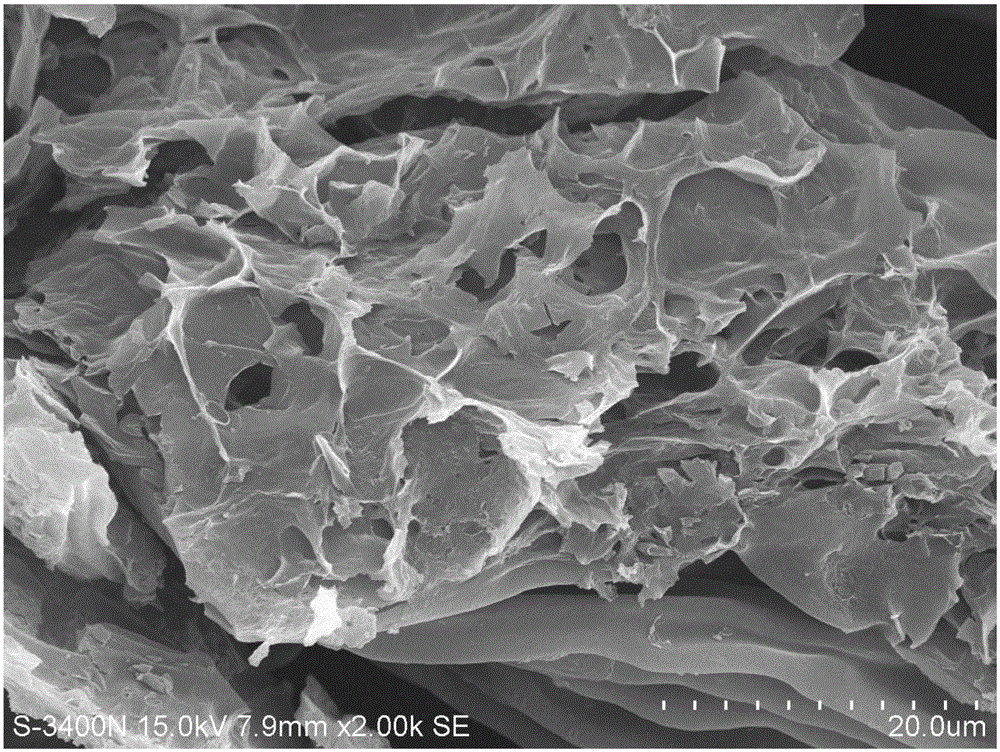

[0038] A preparation method of a graphene-coated microporous silkworm excrement sulfur composite positive electrode material, comprising the following steps,

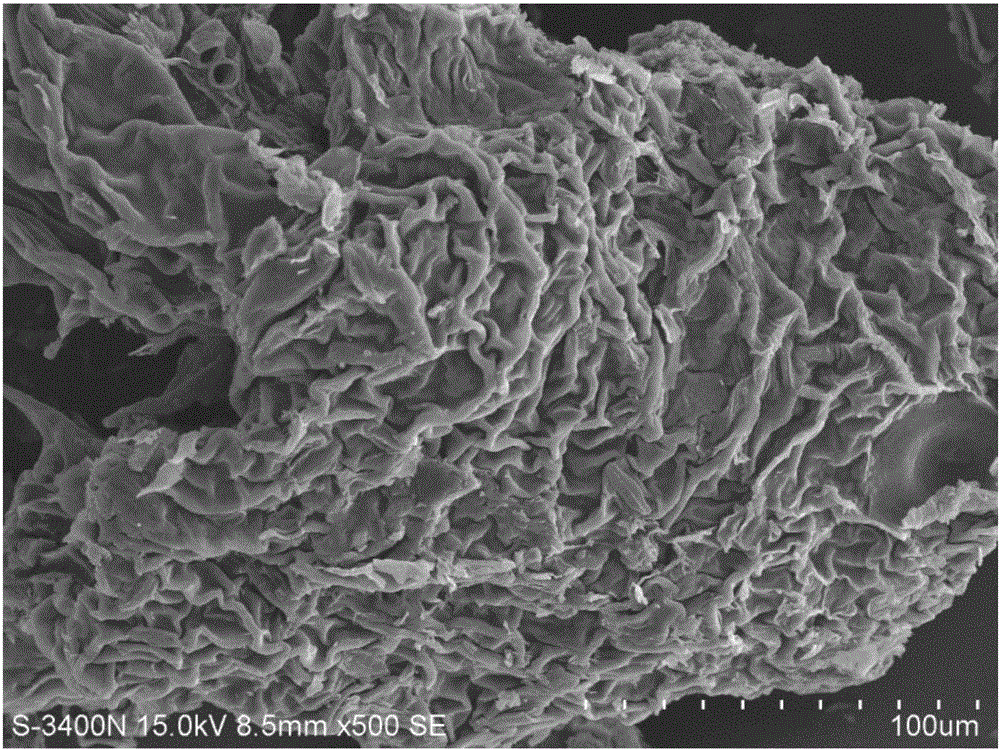

[0039] (1) Preparation of microporous silkworm excrement

[0040] in N 2In the atmosphere, 10.0g of raw silkworm excrement and 10.0g of KOH powder were raised to 800°C at a heating rate of 2°C / min, kept at 800°C for 0.5h, and then cooled to room temperature to obtain microporous silkworm excrement, which was designated as SPCM.

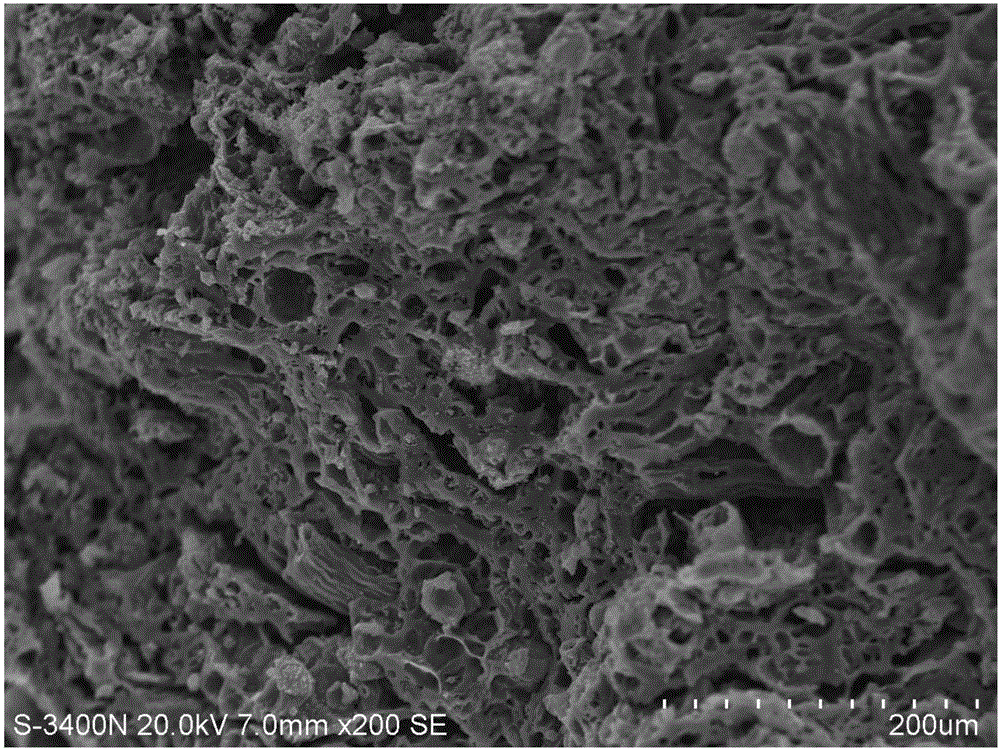

[0041] (2) Vacuum-steam method to load sulfur on microporous silkworm excrement

[0042] Spread 0.3g of SPCM powder in the ark first, and slowly push the ark into the middle of the quartz tube. Pour 1g of sulfur powder into the quartz tube without direct contact with the carbonized SPCM; vacuumize (vacuum degree ≤ 100Pa), seal it and put it into a programmable temperature-controlled drying oven, according to the temperature of 0.5 ℃ / min The heating rate was raised to 120°C, kept at a const...

Embodiment 2

[0047] A preparation method of a graphene-coated microporous silkworm excrement sulfur composite positive electrode material, comprising the following steps,

[0048] (1) Preparation of microporous silkworm excrement

[0049] in N 2 In the atmosphere, 10.0g of raw silkworm excrement and 30.0g of KOH powder were raised to 700°C at a heating rate of 5°C / min, kept at 700°C for 1.0h and then cooled to room temperature to obtain microporous silkworm excrement, which was designated as SPCM.

[0050] (2) Vacuum-steam method to load sulfur on microporous silkworm excrement

[0051] Spread 1.0g microporous silkworm excrement SPCM powder in the ark, and slowly push the ark into the middle of the quartz tube. Pour 2g of sulfur powder into the quartz tube without direct contact with microporous silkworm excrement SPCM; vacuumize (vacuum degree ≤ 100Pa), seal it and put it into a programmable temperature-controlled drying box, according to the temperature of 1.0 The heating rate of °C / m...

Embodiment 3

[0056] A preparation method of a graphene-coated microporous silkworm excrement sulfur composite positive electrode material, comprising the following steps,

[0057] (1) Preparation of microporous silkworm excrement

[0058] in N 2 In the atmosphere, 10.0g of raw silkworm excrement and 40.0g of KOH powder were raised to 600°C at a heating rate of 3°C / min, kept at 600°C for 2.0h, and then cooled to room temperature to obtain microporous silkworm excrement, which was designated as SPCM.

[0059] (2) Vacuum-steam method to load sulfur on microporous silkworm excrement

[0060] Spread 2.0g microporous silkworm excrement SPCM powder in the ark, and slowly push the ark into the middle of the quartz tube. Pour a certain amount of sulfur powder into the quartz tube, without direct contact with the microporous silkworm excrement SPCM; vacuumize (vacuum degree ≤ 100Pa), seal it and put it into a programmable temperature-controlled drying box, according to the following The temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com