Activated carbon waste gas spraying treatment equipment with quick release structure

A technology for waste gas treatment and activated carbon, which is applied in the filtration loop, the use of liquid separation agents, filtration and separation, etc., can solve the problems of single spray treatment effect, difficult cleaning and maintenance, inconvenient loading and unloading, etc., to achieve waste gas treatment methods. Diversified, improved purity, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

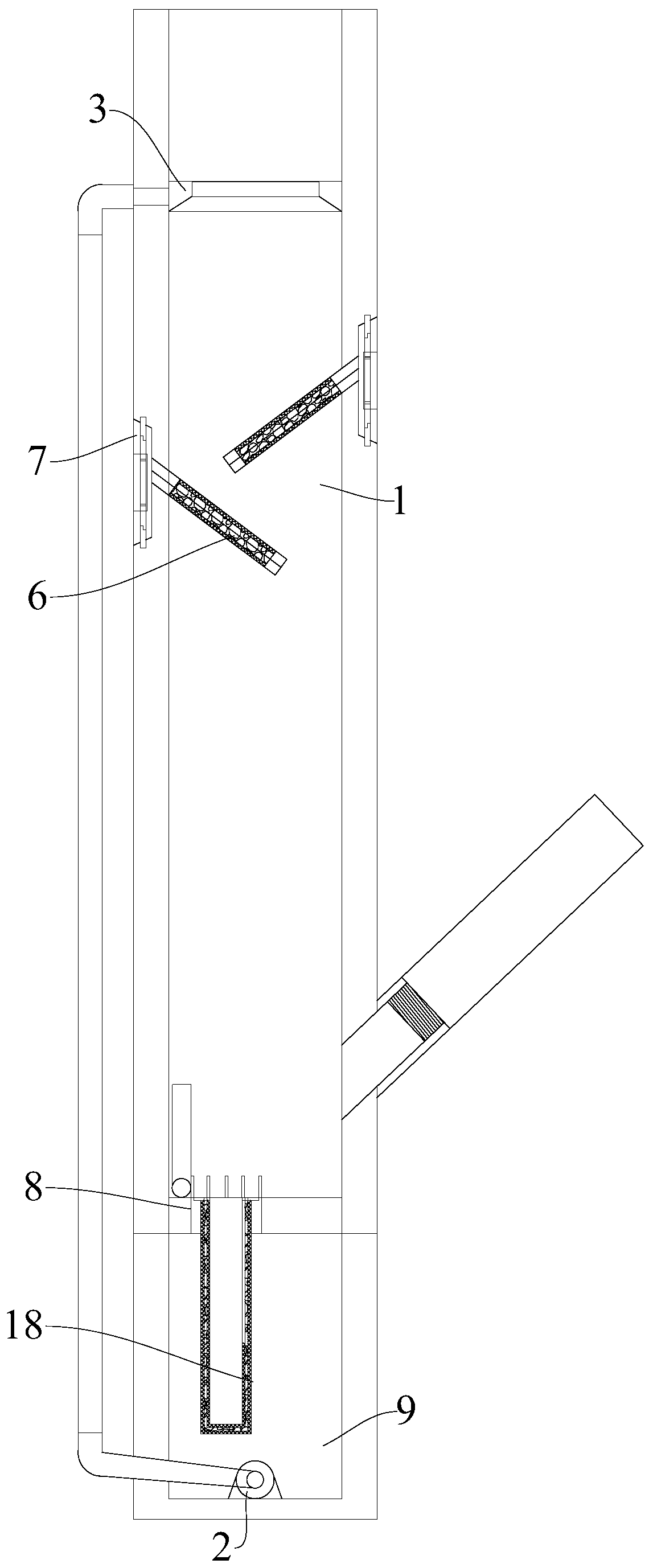

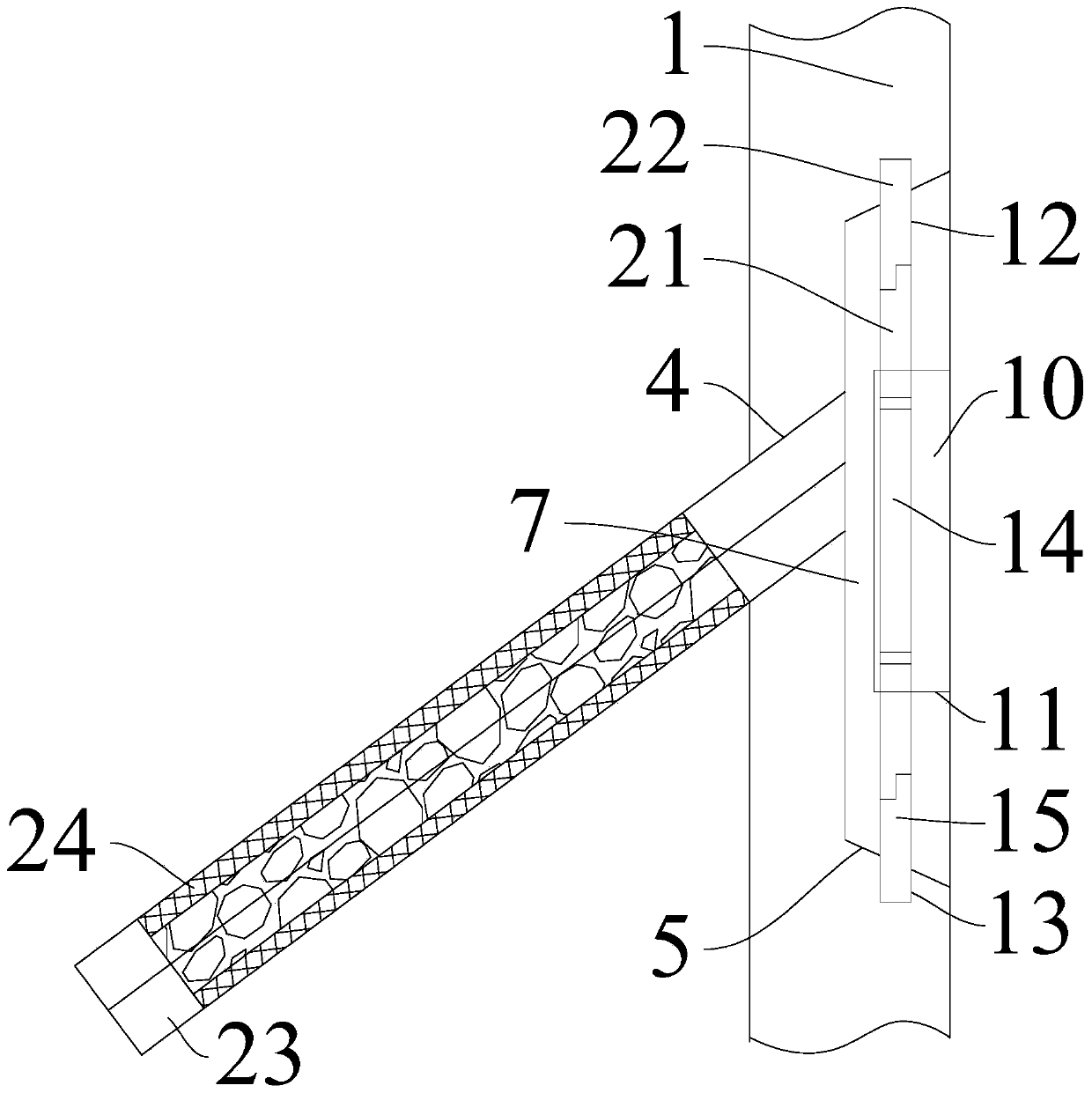

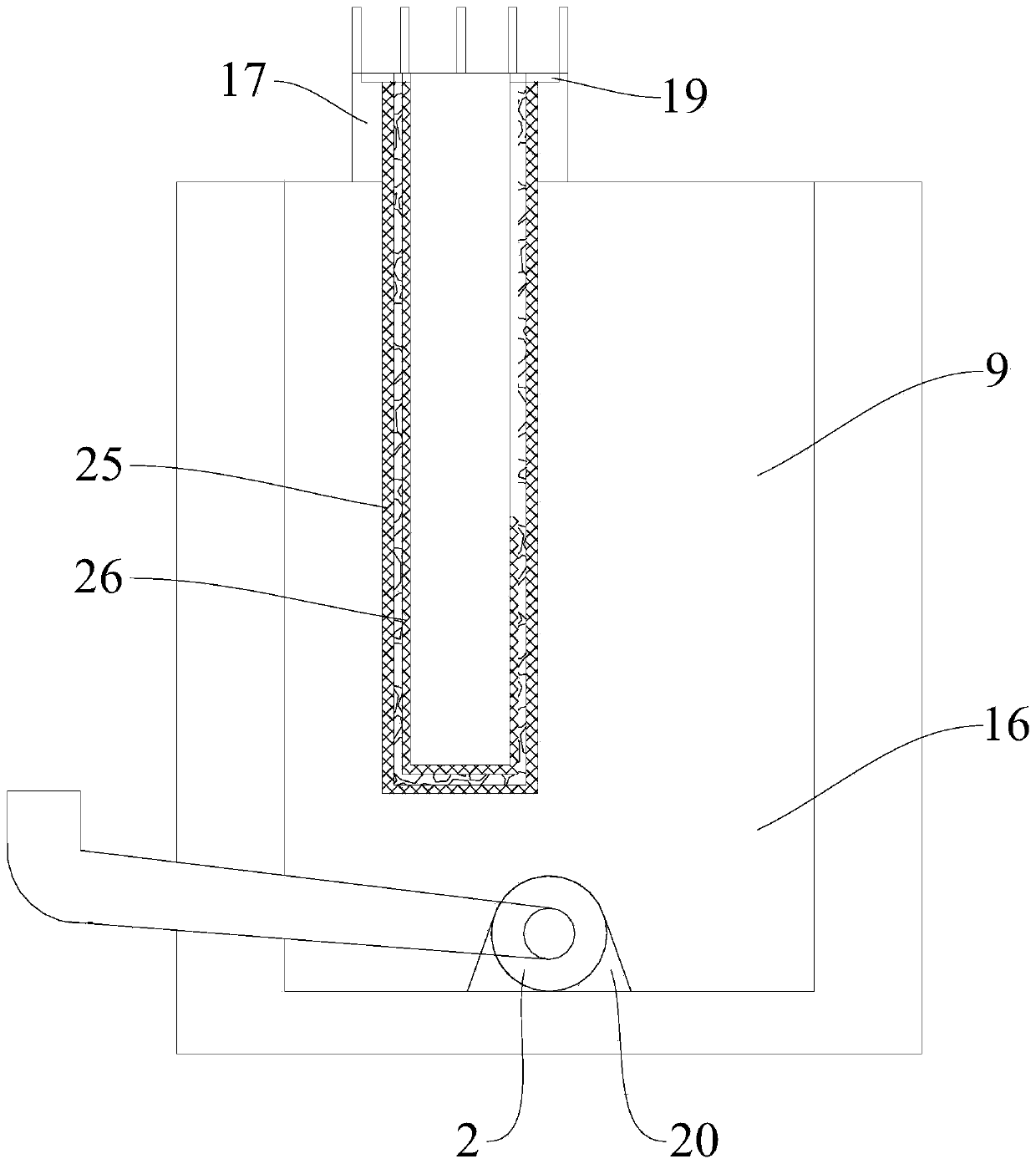

[0016] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0017] figure 1 , figure 2 with image 3 The shown type of activated carbon waste gas spray treatment equipment with quick release structure includes a waste gas treatment tower body 1 and a small booster water pump 2 powered by an external power supply and controlled opening and closing. The upper end of the waste gas treatment tower body 1 is fixedly connected with a ring Spray pipe 3, two oblique sockets 4 are staggered on the inner walls of both sides of the waste gas treatment tower body 1, and the outer surface of the waste gas treatment tower body 1 is provided with an outer slot 5 communicating with the inclined socket 4, A metal storage filter frame 6 with bu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap