Active carbon fiber device and method for adsorbing, recovering and treating organic waste gas

A technology of activated carbon fiber and organic waste gas, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of increased waste gas treatment costs, inability to waste steam, and occupying adsorption capacity, so as to improve the effective utilization rate and avoid Poor adsorption effect, avoid repeated adsorption effect

Inactive Publication Date: 2007-01-31

CHINA PETROLEUM & CHEM CORP +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Usually, in order to improve the recovery rate of organic solvents, it is necessary to lower the temperature of the condensate, but the condensed water does not need low temperature, but because the organic solvent and water vapor are all cooled at the same temperature, not only the energy consumption of the coolant is high, but also The recovery effect of organic solvent is not easy to guarantee

[0012] ② After desorption, the adsorption core begins to enter the adsorption state without sufficient cooling. Since the temperature inside the activated carbon fiber is very high in the initial stage of adsorption (close to the temperature of desorption steam), the adsorption rate is very low, and the organic pollutants in the exhaust gas high concentration

During this time period, the pollutant concentration in the gas discharged from the adsorber is high and the compliance rate is low

[0013] ③After the exhaust gas enters the adsorber, there is no diffusion facility, and part of the air flow is directly blown to the activated carbon fiber adsorption core near the air inlet, which makes the gas velocity on the local activated carbon fiber too high, resulting in a large amount of adsorption on most activated carbon fibers. When there is a surplus, certain parts have penetrated ahead of time, so the adsorption has to be stopped and desorption started, resulting in problems such as low adsorption rate, short adsorption cycle, high desorption frequency, and increased waste gas treatment cost.

Since the specific gravity of the desorbed organic vapor is relatively light, it is easy to accumulate in the upper part of the adsorber, and the organic vapor cannot be discharged naturally at the bottom of the discharge port, so more steam is needed to entrain it, which not only causes waste of steam but also cannot desorb it. The organic solvent gas is completely discharged, and is re-adsorbed on the activated carbon fiber in the next adsorption process, occupying the effective adsorption capacity.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0049] Embodiment 1 Acetone waste gas adsorption test

[0050] Adsorber outlet

Embodiment 2

[0051] Example 2 N-hexane waste gas adsorption test

[0052] Adsorber outlet

Embodiment 3

[0053] Embodiment 3 Desorption gas outlet position and acetone residual concentration test

[0054] steam consumption

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

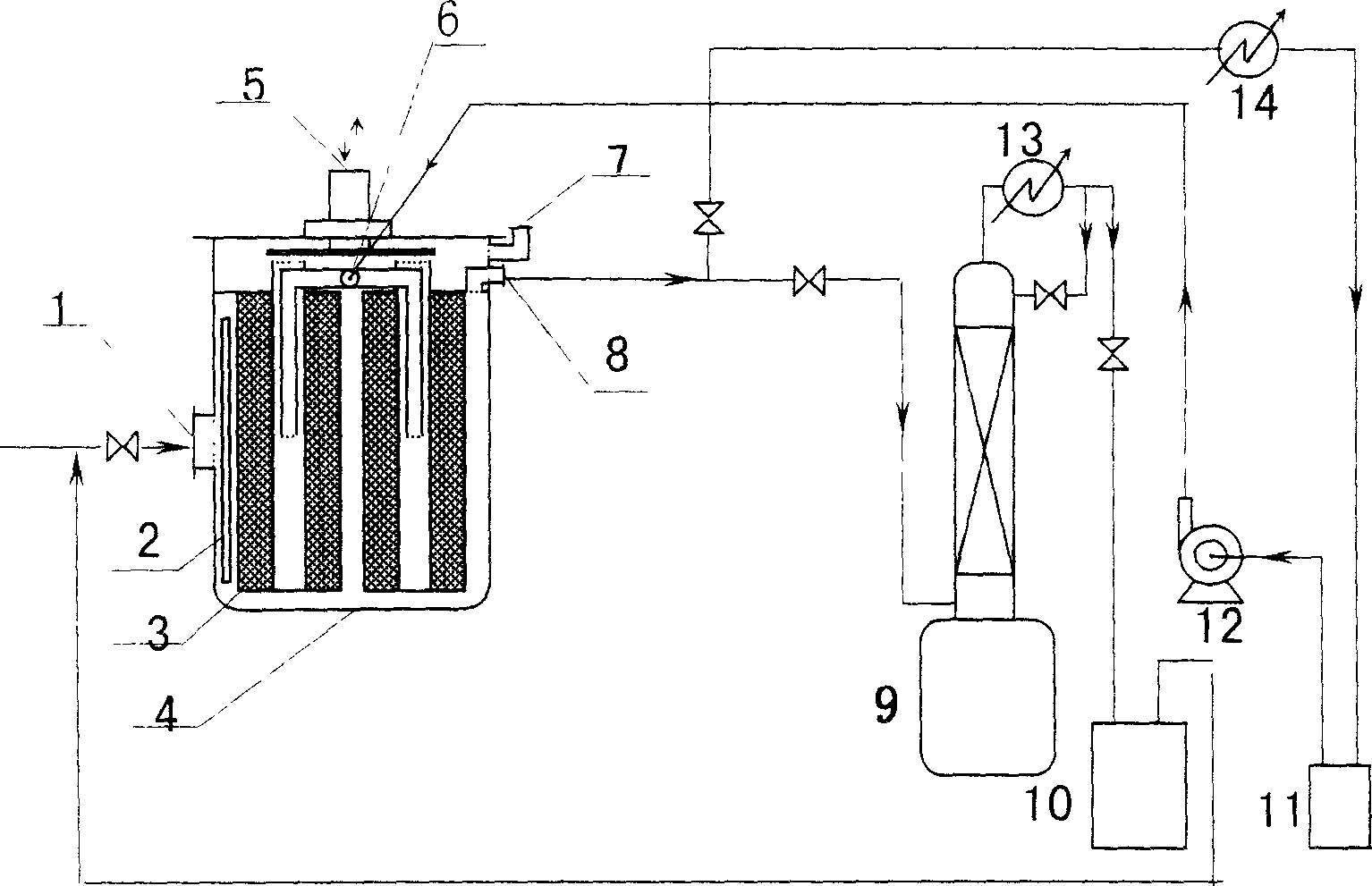

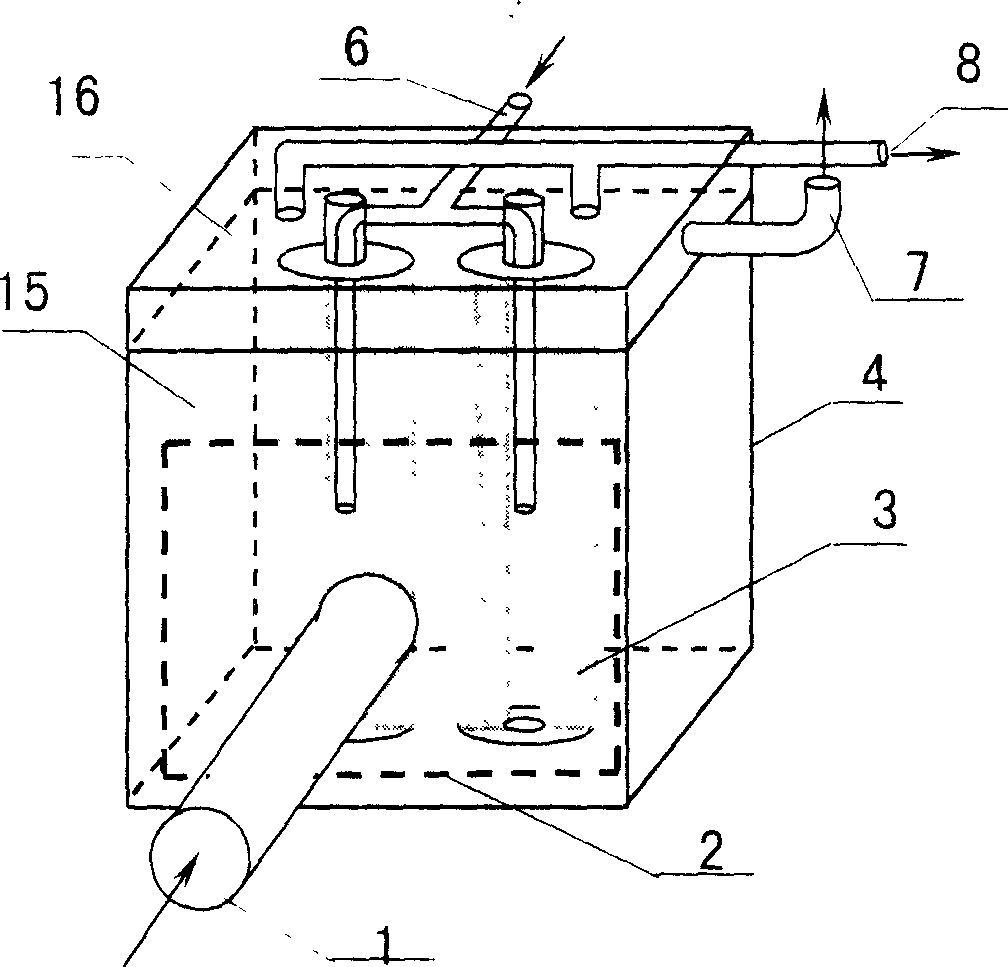

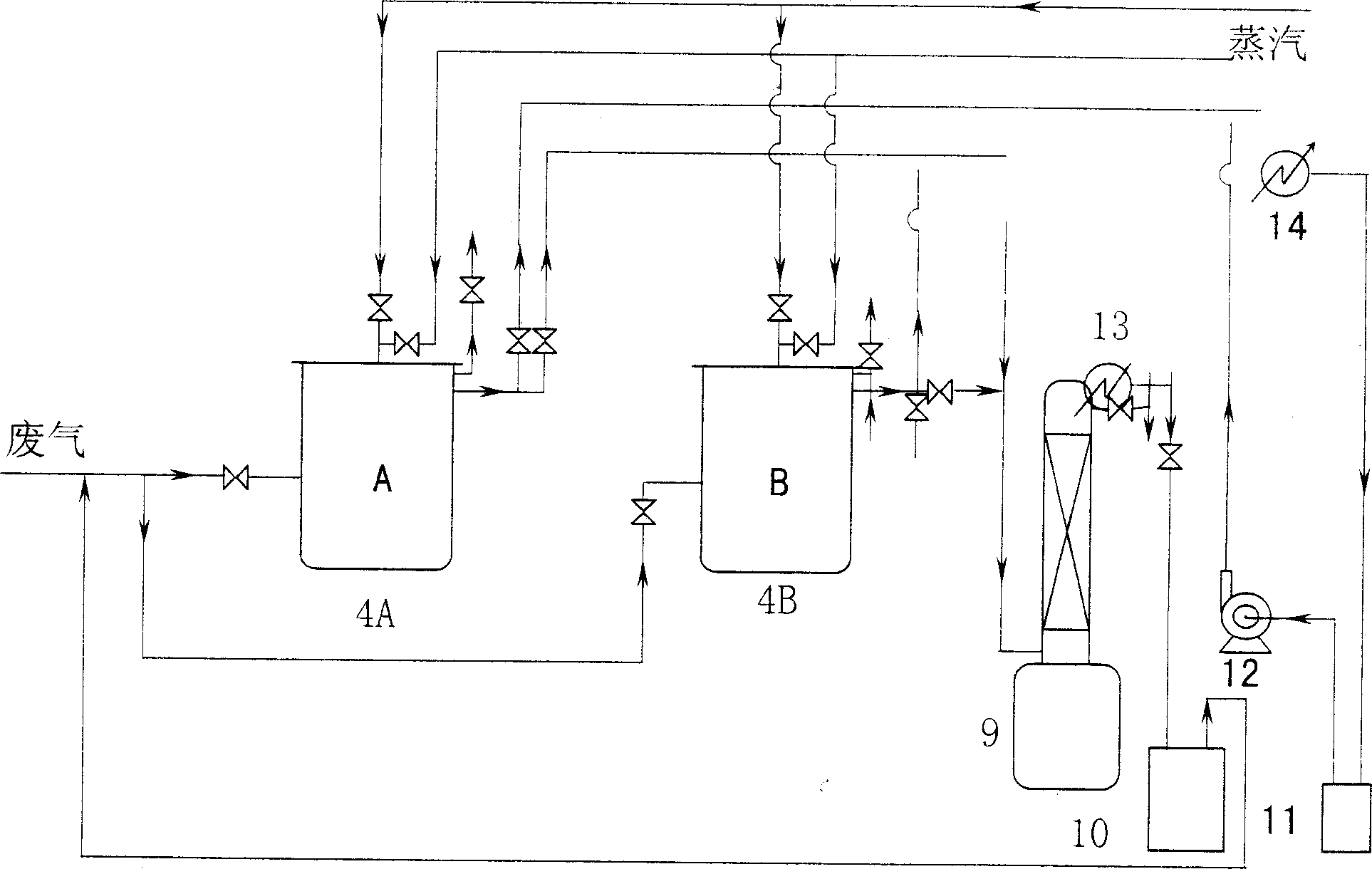

The present invention features that the waste organic gas recovering and treating apparatus includes also one rectifying and recovering system, which comprises rectifying tower between the outlet of analyzed gas and the condensator and solvent accepting trough between the rectifying tower and the condensator and is for recovering the organic solvent; and may includes also one analyzed gas by-pass cooling system and one gas distributing baffle. The method of recovering and treating waste organic gas may be alternate single stage adsorption-analysis-cooling and dehumidifying in two or three serially connected adsorbors, and through connection and arrangement of pipeline and valves, uninterrupted recovering and treating of waste organic gas is realized.

Description

technical field [0001] The invention relates to a device and a method for recovering and treating organic pollutants in waste gas with activated carbon fibers. More specifically, it relates to a device and method for recovering and treating organic waste gas that uses activated carbon fibers to absorb volatile organic pollutants in waste gas, then desorbs them with high-temperature water vapor, and condenses them into liquid organic solvents with a cooler. Background technique [0002] Organic waste gas refers to the gas of organic solvents volatilized into the atmosphere in petrochemical, electronics, textile, and painting production, such as benzene, toluene, styrene, acetone, chlorinated alkanes, cycloalkanes, n-hexane, ether, etc. [0003] At present, the main method to deal with this kind of waste gas is adsorption. There are two kinds of adsorbents, granular activated carbon and activated carbon fiber. Compared with granular activated carbon, activated carbon fiber h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): B01D53/04

Inventor 高明华叶晶菁薛金成柴本忠赵璞梁云刘继敏侯秀华

Owner CHINA PETROLEUM & CHEM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap