One-way heart pump centrifuge internal flow channel

A centrifuge and centripetal pump technology, applied in the field of centrifuges, can solve the problems of equipment weight, large volume, complex flow channel structure, blocking of blanking holes, etc., to achieve effective separation and purification, reduce manufacturing costs, and lengthen flow. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

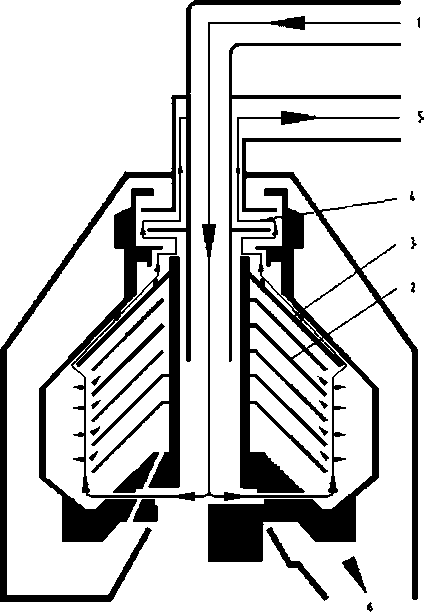

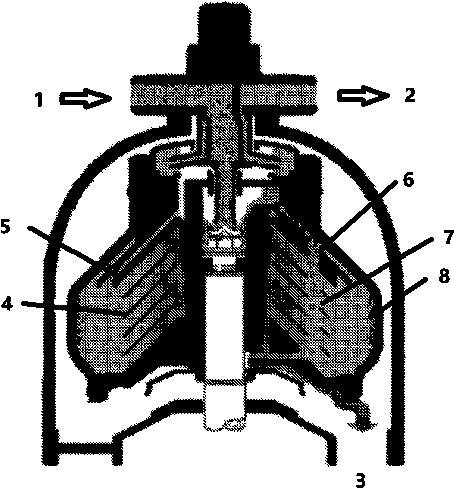

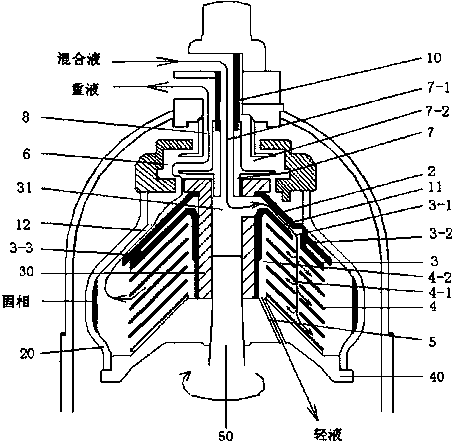

[0026] Figure 1-3 Shown is a settling disc centrifuge with a unidirectional heart pump structure. As shown in the figure, the three types of centrifuges all have a mixed liquid inlet, a heavy liquid outlet and a light liquid outlet. figure 1 The centrifuge with the structure shown has a mixed liquid inlet 1, a heavy liquid outlet 5, and a light liquid outlet 6. The centrifuge with this structure adopts the liquid inlet hole in the rotating center of the drum to enter the liquid, and then distributes to the surroundings of the drum after passing through the bottom guide plate, and separates the mixed liquid in the process of rising upwards, and the light liquid moves to the rotating center of the drum and enters the disc. After the area, it flows to the light liquid outlet by its own gravity and is discharged out of the drum system....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap