Batch production device for beveled spliced plastic-wood plates

A mass production, plastic board technology, used in wood processing appliances, circular saws, sawing components, etc., can solve problems such as low production efficiency, and achieve high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0024] first implementation

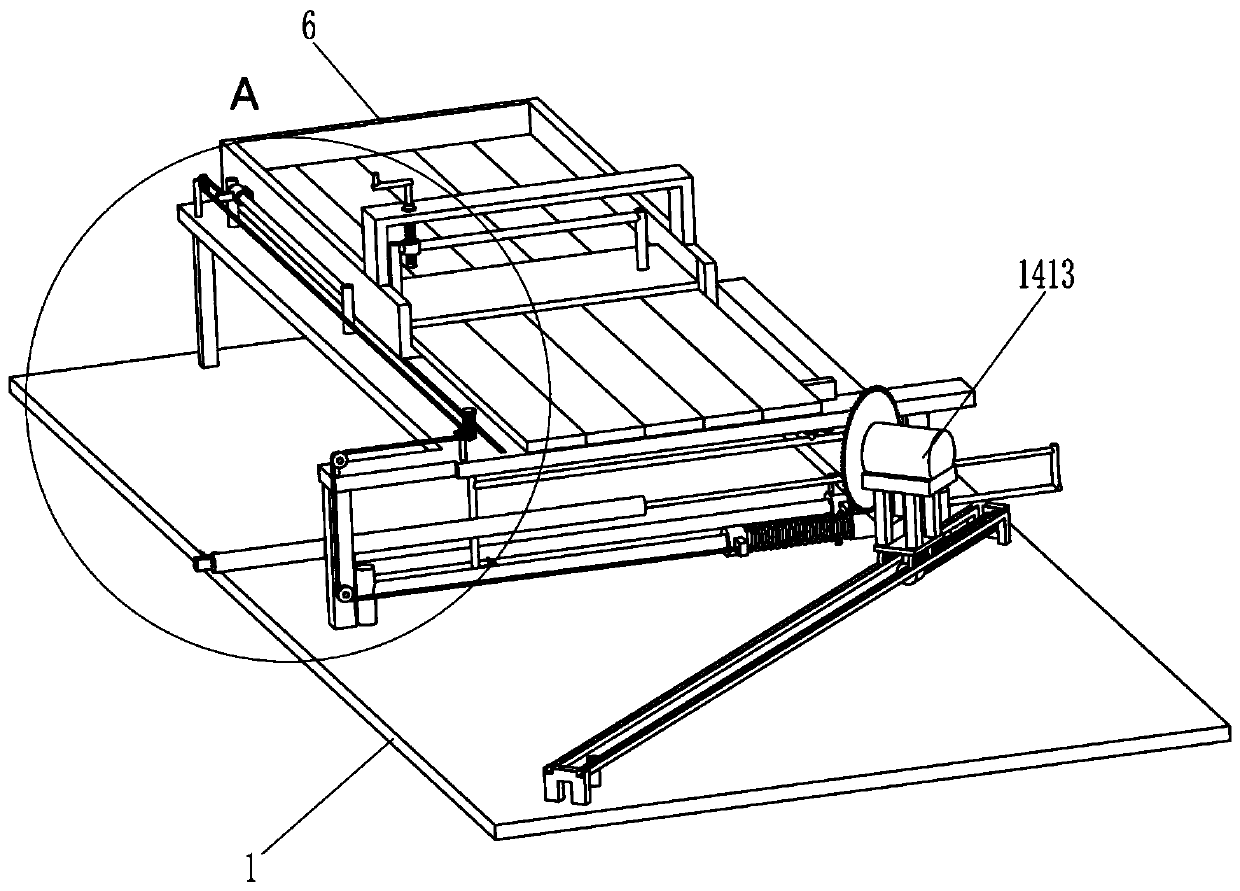

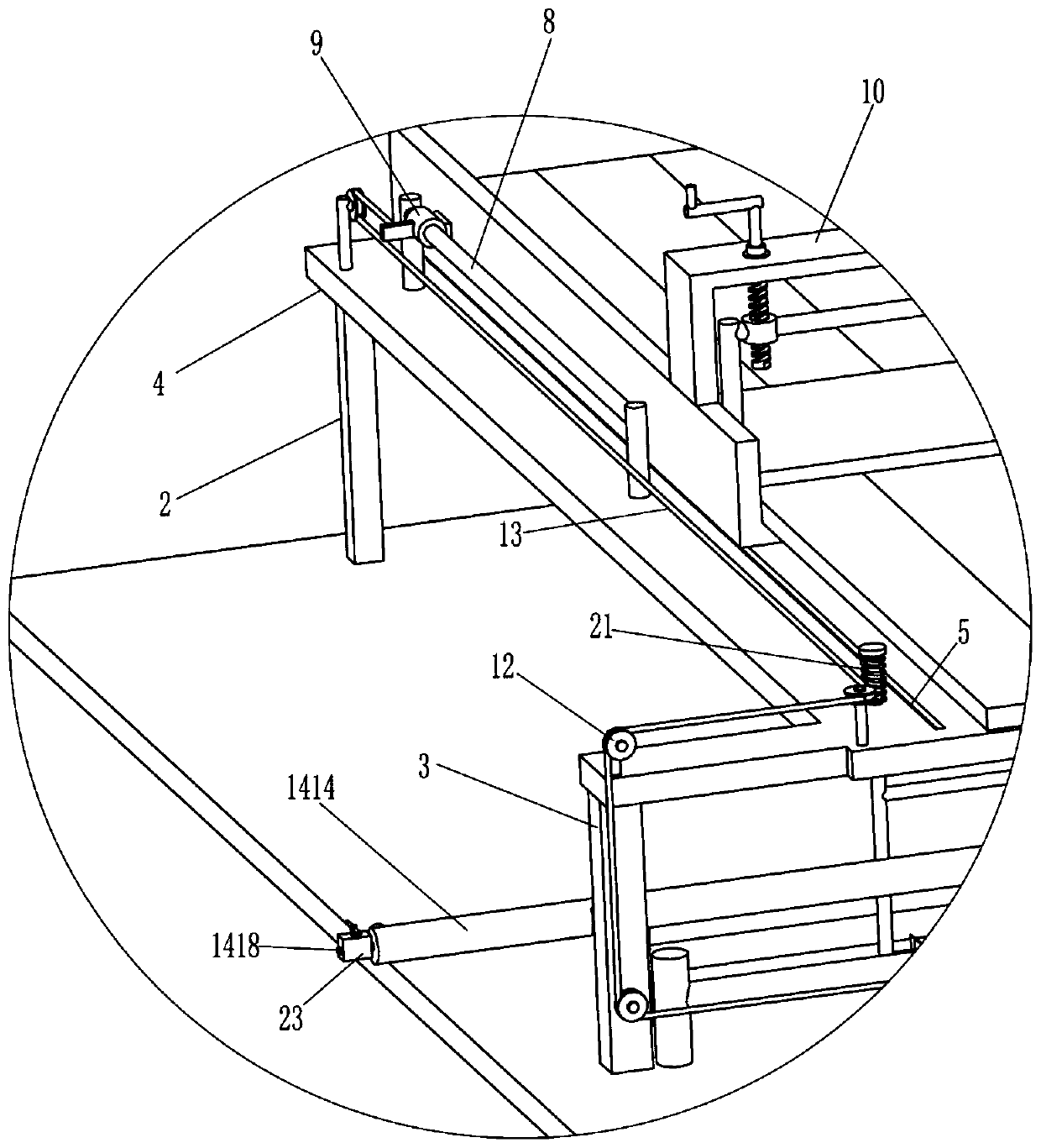

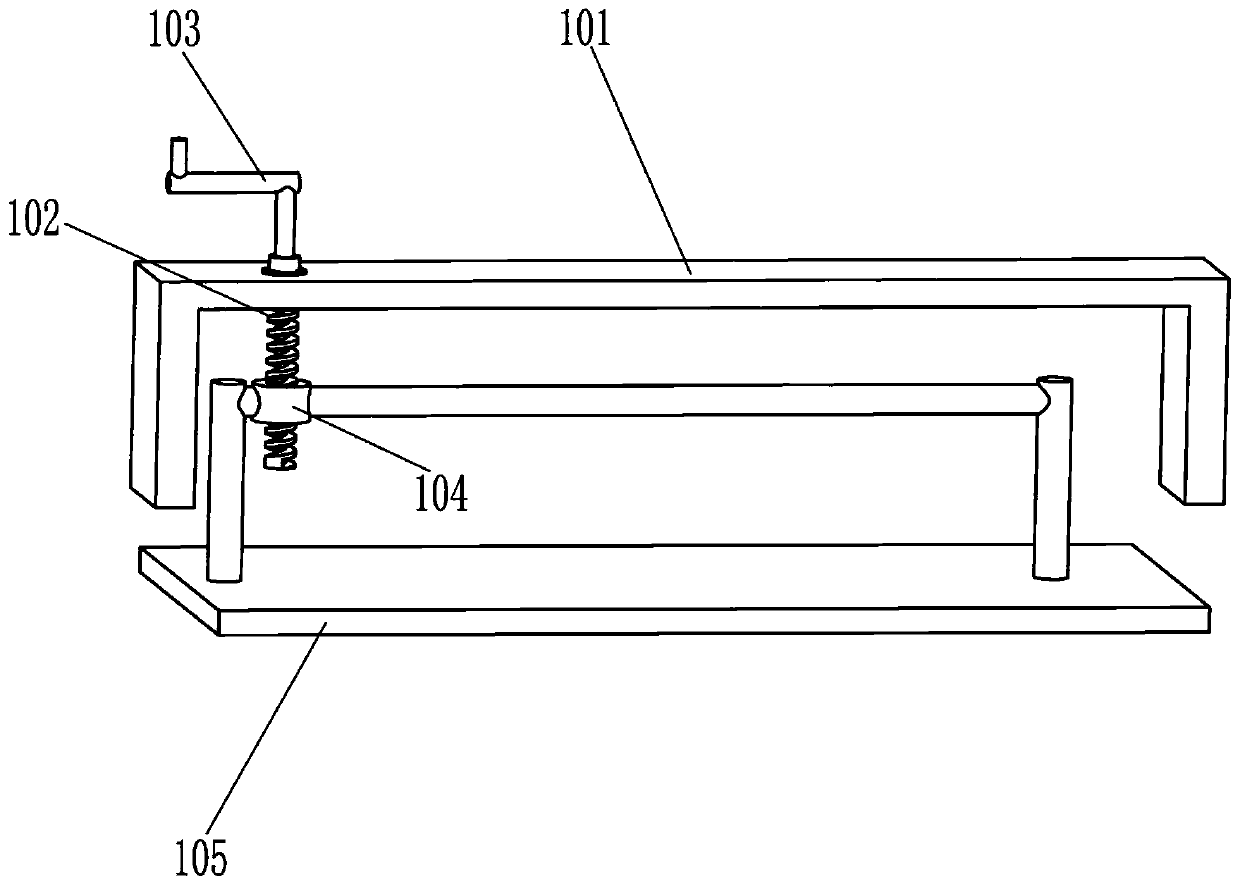

[0025] A mass production device for splicing plastic wood boards with inclined planes, such as Figure 1-8 As shown, it includes a bottom plate 1, a first bracket 2, a second bracket 3, a placement plate 4, a block 401, a placement frame 6, a first roller 7, a first guide rod 8, a first sliding sleeve 9, and a pressing assembly 10. Guide wheels 12, pull ropes 13 and cutting components 14, the left and right sides of the top rear side of the bottom plate 1 are equipped with the first bracket 2 through bolts, and the left and right sides of the front side of the top of the bottom plate 1 are equipped with the second bracket through bolts 3. A placement plate 4 is installed on the top of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap