Multi-piece glass base

A piece of glass and bottom plate technology, which is applied in the field of glass product preparation, can solve the problems of low glass printing efficiency, achieve the effects of reducing color and scratches, reducing time, and improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

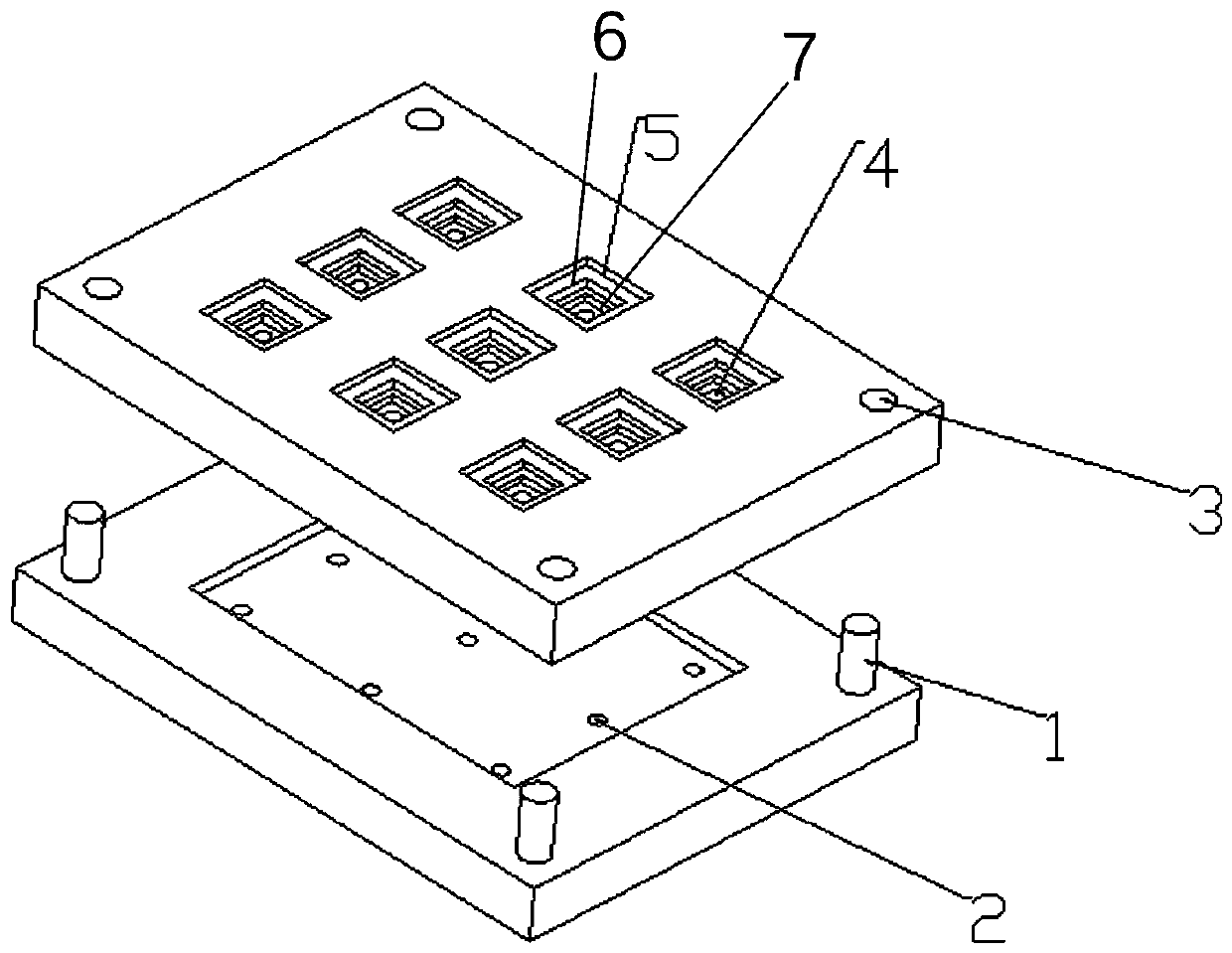

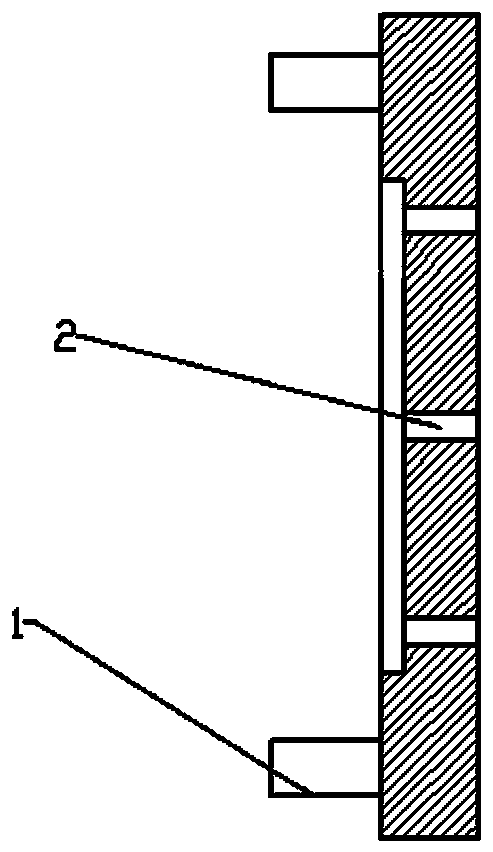

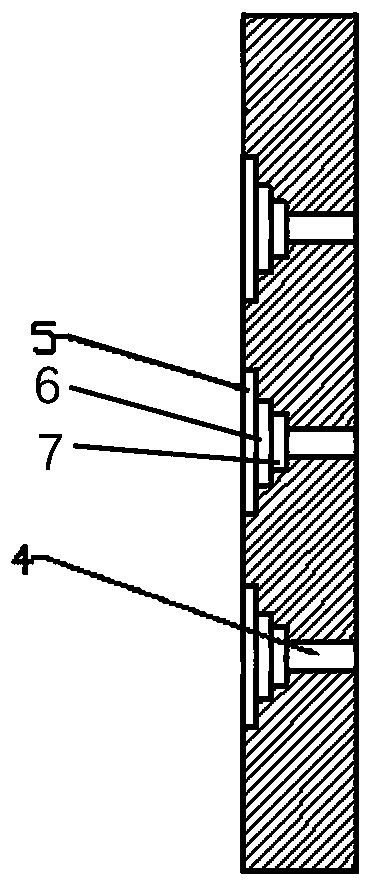

[0013] like figure 1 , figure 2 , image 3 As shown, a multi-piece glass base includes a bottom plate and a base. The base plate is a square bakelite board, and the surface of the base plate is provided with four positioning pins near the four corners. The positioning pin 1 is cylindrical, and the height of the positioning pin 1 is the same as that of the base. There is a square recessed area in the middle of the bottom plate, and nine first vacuum suction pipes 2 arranged in a 3×3 manner are arranged in the recessed area, and the first vacuum suction pipes 2 run through the bottom plate from top to bottom. The base is located above the base plate and is identical in size and shape with the base plate. The position of the base corresponding to the positioning bolt 1 is provided with a positioning hole 3, and the diameter of the positioning hole 3 is set to just pass through the positioning bolt 1 for positioning the base so that it does not shift. The position correspondin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap