Protective assembly and washing machine

A technology of components and positioning parts, which is applied in the field of washing machines, can solve the problems of unstable assembly, time-consuming and labor-intensive assembly, and cumbersome assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

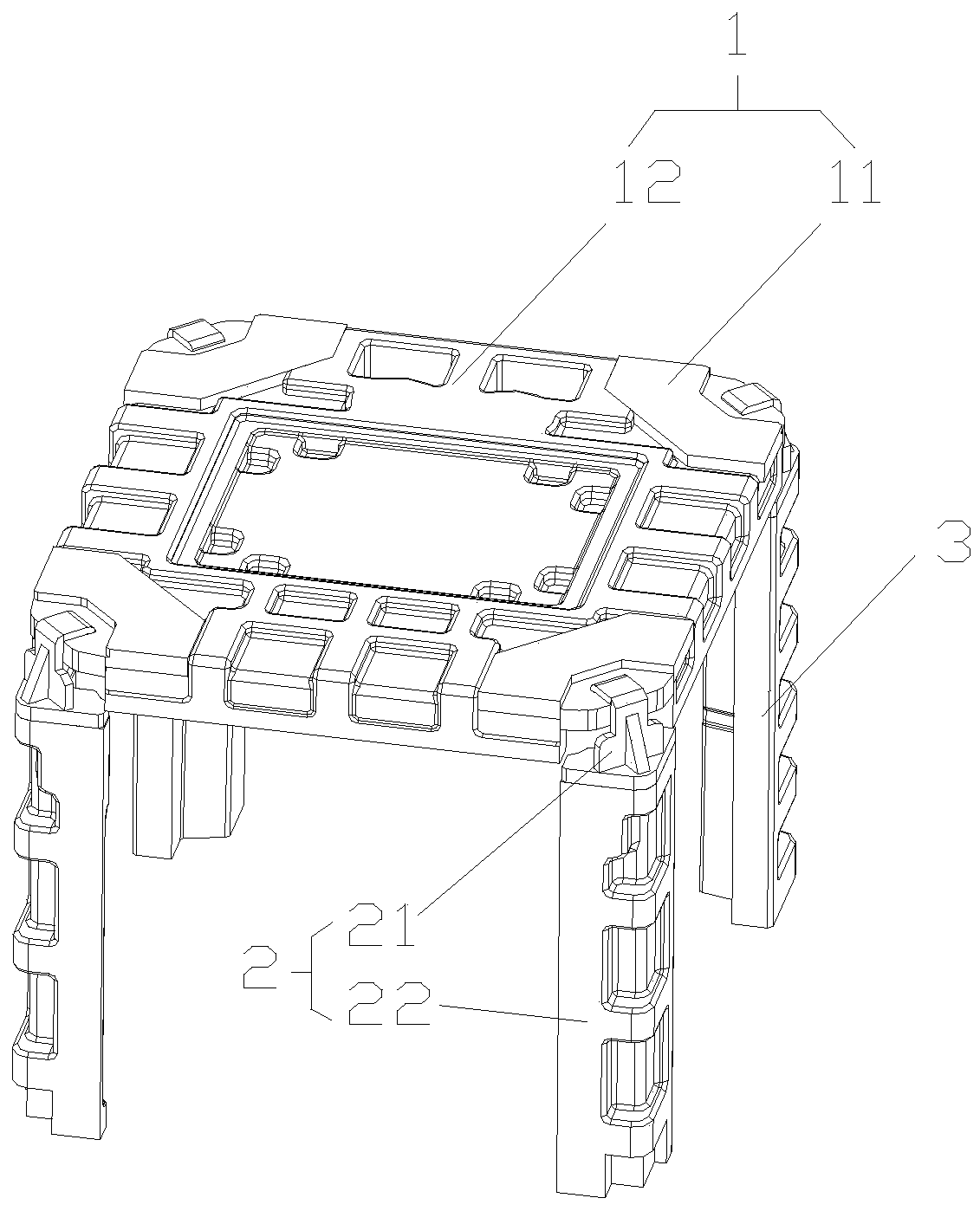

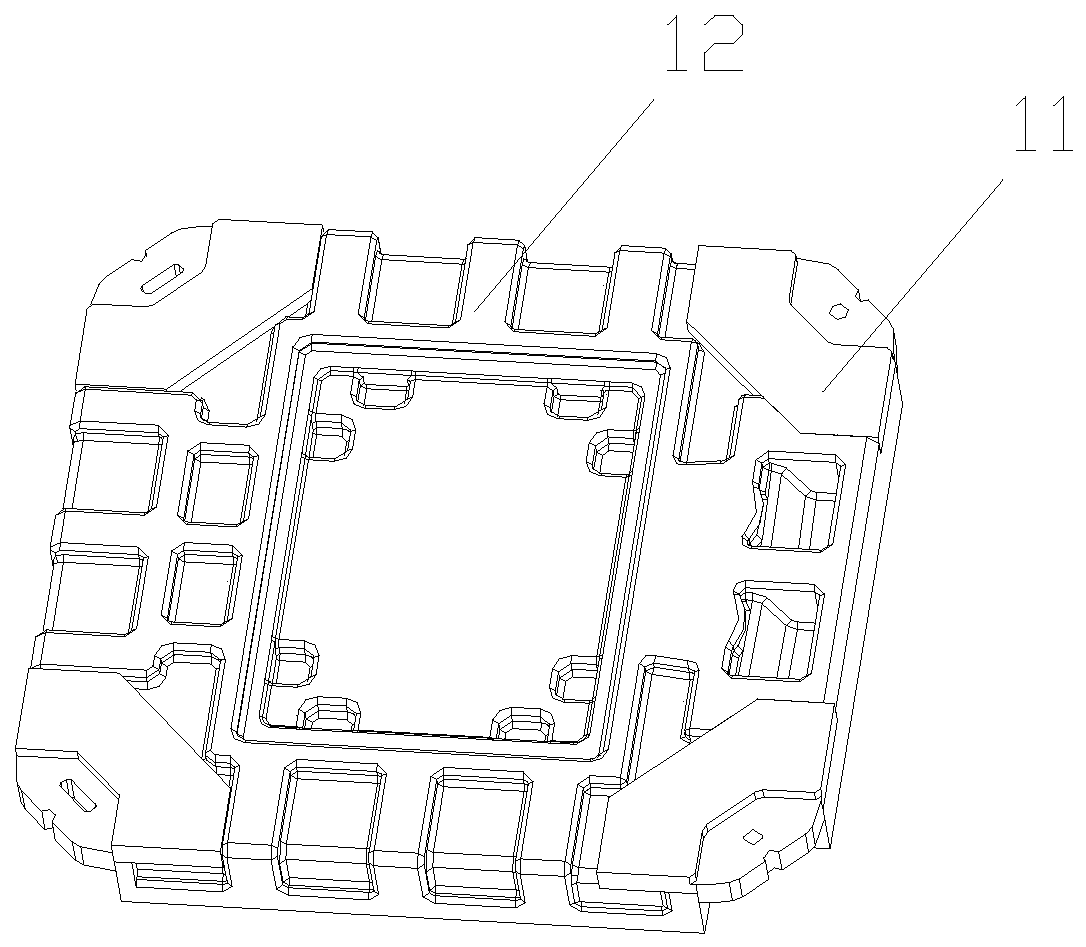

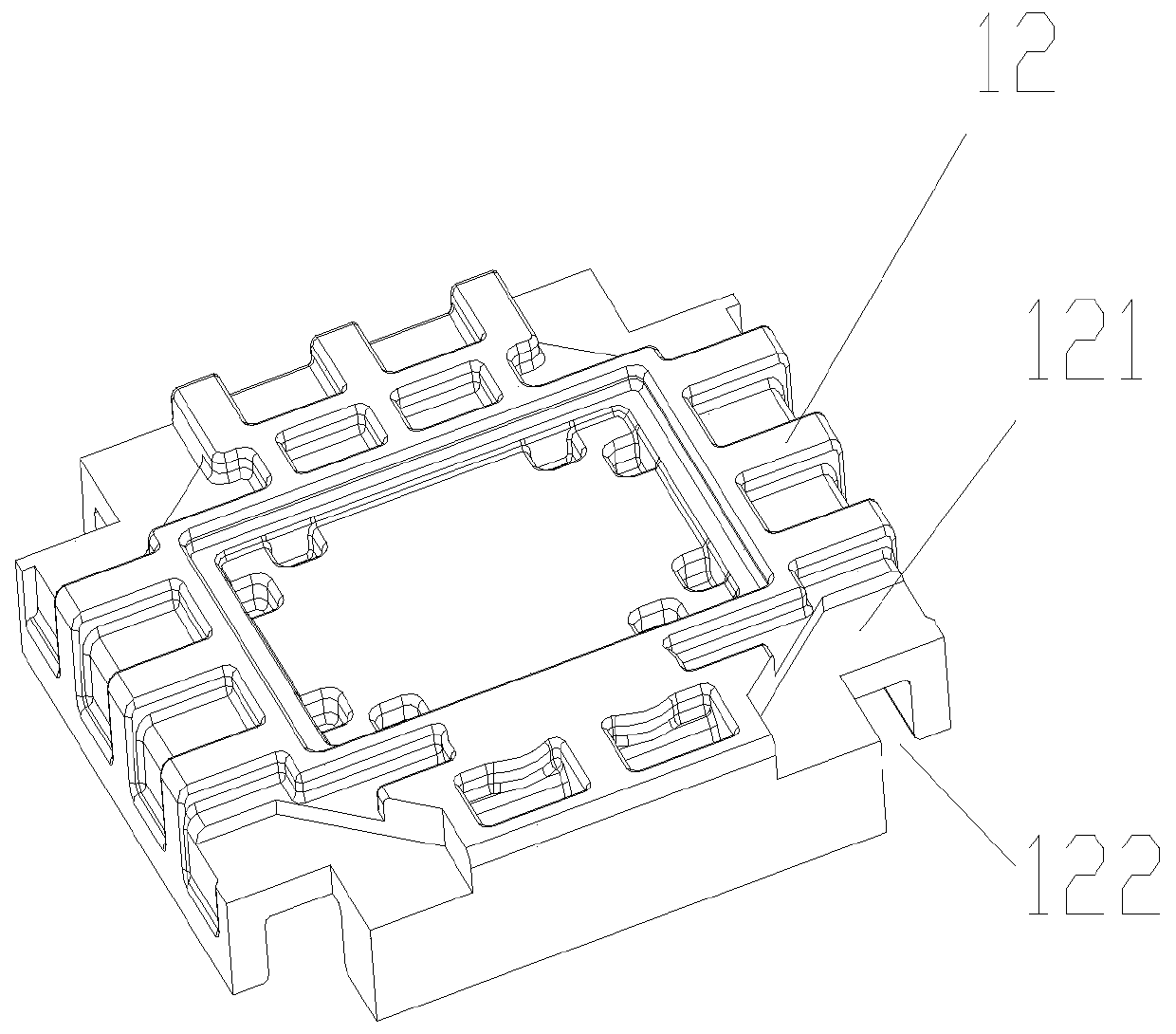

[0029] see in conjunction Figure 1 to Figure 8 As shown, according to an embodiment of the present application, a protective assembly includes:

[0030] A top 1, the top 1 is provided with a base structure 11;

[0031] A column assembly, one end of the column assembly is connected to the base structure 11 in a suspended manner.

[0032] The traditional column assembly is connected to the top 1 by means of suspension, and the two are not easy to be separated. It is convenient to assemble the top 1 and the column assembly in advance, which can ensure the stability of the column and is not easy to topple, making the assembly of the column and the top 1 convenient and improving production. efficiency.

[0033] In some embodiments, the base structure 11 includes a positioning structure, which is used to limit the suspension position of the column assembly on the base structure 11, and the suspension position of the column assembly on the base structure 11 can be guided and limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com