Detachable winding shaft structure

A reeling and detachable technology, applied in the field of detachable reeling structure, can solve the problem of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

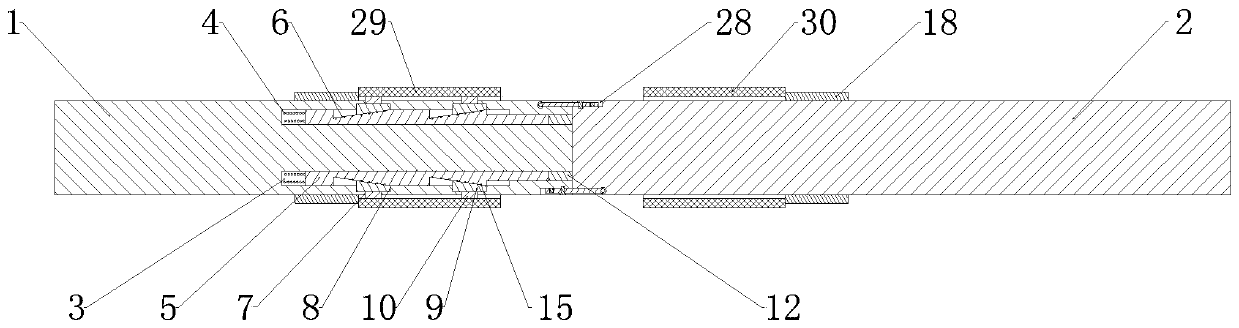

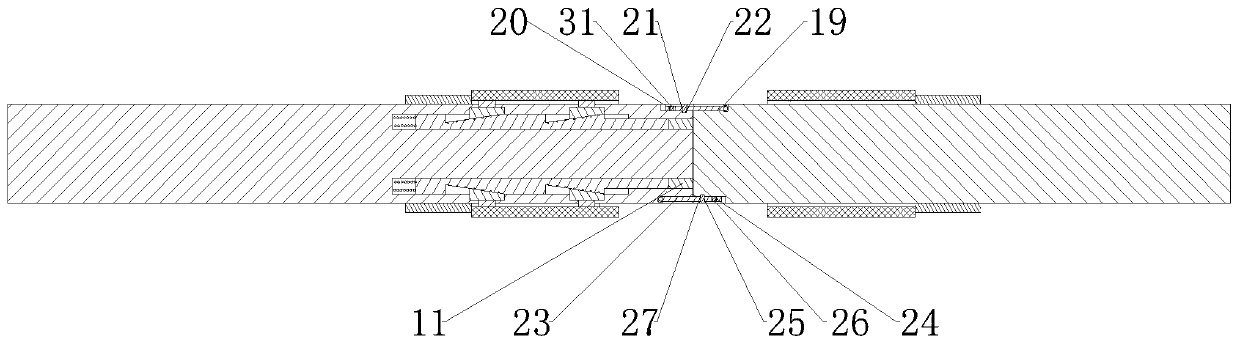

[0047] Such as Figure 1 to Figure 4 As shown, the detachable winding shaft structure includes half shaft A1 and half shaft B2, and half shaft B2 is detachably connected to half shaft A1 through a connecting component;

[0048] The inner ends of the half-shaft A1 and the half-shaft B2 are provided with a number of locking grooves 3 arranged in a ring. The locking groove 3 is connected with a locking rod 5 that can slide relative to the locking groove 3 through an elastic member 4. The locking rod 5 The top of 5 is provided with several jacking notch grooves 6, and the bottom surface of the jacking notch grooves 6 is arranged on an inclined plane, and the depth of the jacking notch grooves 6 is gradually deepened toward the direction close to the elastic member 4;

[0049] The outer ring surfaces of the semi-axis A1 and the semi-axis B2 are provided with telescopic notches corresponding to the number of jacking notch grooves 6. The telescopic notches have telescopic openings 7 ...

Embodiment 2

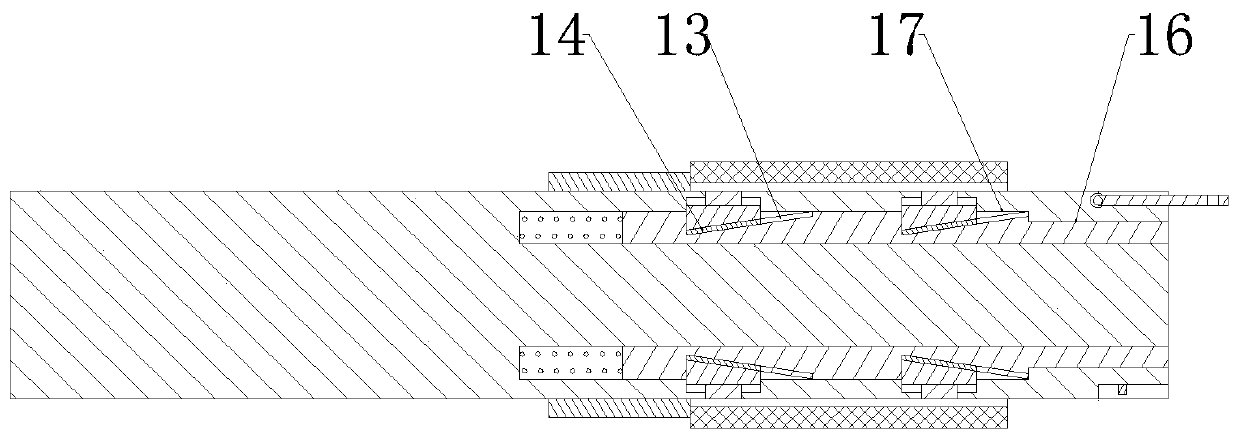

[0055] This embodiment makes the following further limitations on the basis of embodiment 1: the groove bottom of the jacking notch groove 6 is provided with a chute 13 with a small opening and a large inner cavity;

[0056] The bottom end of the jacking slider 9 is provided with a connecting protrusion 14 capable of slidingly fitting with the sliding groove 13 .

Embodiment 3

[0058] This embodiment is further defined as follows on the basis of Embodiment 1: the bottom surface of the jacking notch groove 6 is provided with a ball 15 capable of acting on the bottom end surface of the jacking slider 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com