Foot type robot for overhauling heat transfer pipes of steam generators of multiple specifications

A technology of steam generator and heat transfer tube, applied in the field of maintenance robots and footed robots, can solve problems such as poor structural adaptability and inflexible movement modes, and achieve a large working space, flexible and diverse movement modes, and strong structural adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

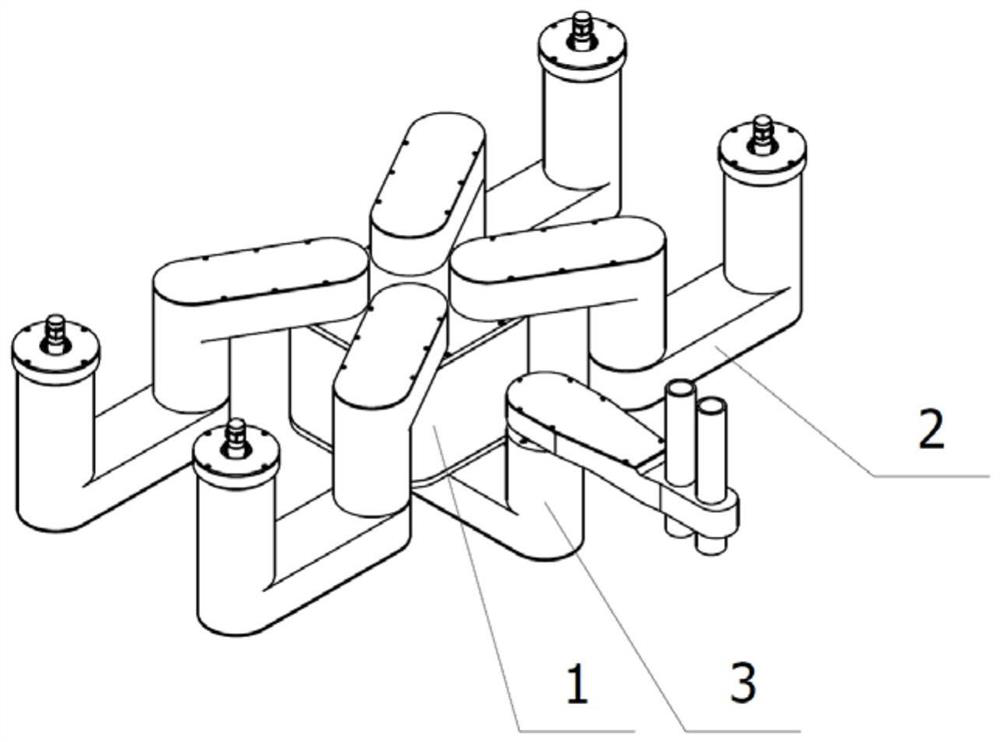

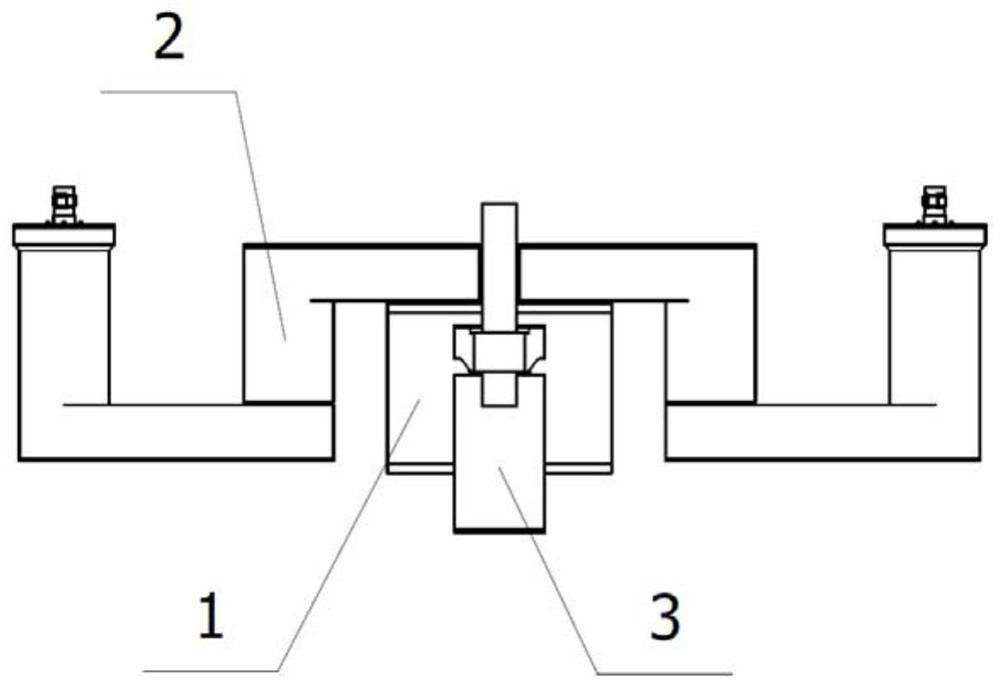

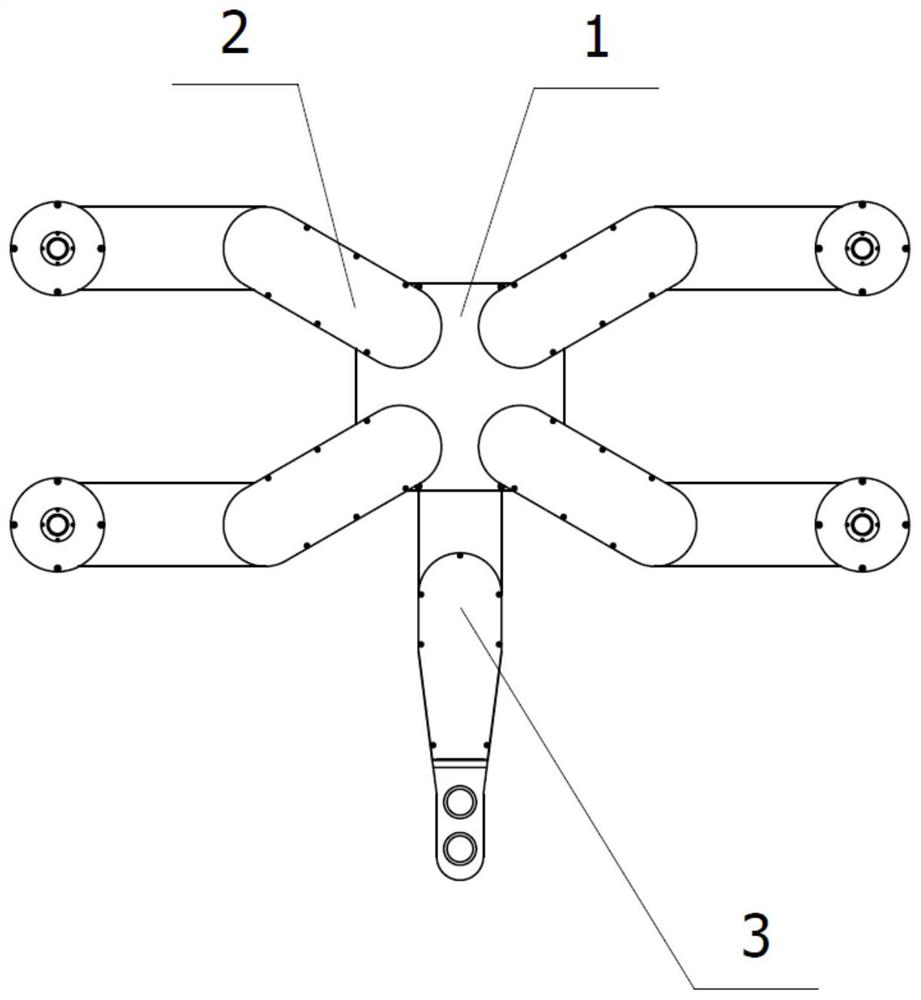

[0041] Specific implementation mode one: combine Figure 1-Figure 24 To illustrate this embodiment, this embodiment provides a legged robot for overhauling heat transfer tubes of multi-standard steam generators, which includes a base module 1, an operating arm module 3 and four leg modules 2; The seat module 1 includes a base box 4, a shoulder joint motor module 8 and four hip joint motor modules 7; four hip joint motor modules 7 are arranged on the upper end of the base box 4, and A shoulder joint motor module 8 is provided, the top output end of each hip joint motor module 7 is respectively connected to a leg module 2 , and the bottom output end of the shoulder joint motor module 8 is fixedly connected to the working arm module 3 . It is used to realize the swing of the shoulder joint of the working arm module 3. The leg module 2 is used to realize the walking of the robot, and the working arm module 3 is installed under the base module 1 to realize the positioning and main...

specific Embodiment approach 2

[0042] Specific implementation mode two: combination Figure 1-Figure 15 This embodiment is described. This embodiment provides a legged robot for overhauling multi-standard steam generator heat transfer tubes. The leg module 2 includes a leg-joint module 9 and a leg-two-joint module 10; One end of the first joint module 9 is fixedly connected to the top output end of the hip joint motor module 7, and the other end of the first joint module 9 of the leg is connected to the fixed end of the second joint module 10 of the leg. The leg-joint module 9 is fixedly connected to the output end of the hip joint motor module 7 to realize the swing of the hip joint of the leg module 2, and other structural connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0043]Specific implementation mode three: combination Figure 1-Figure 15 This embodiment is described. In this embodiment, a legged robot for overhauling multi-standard steam generator heat transfer tubes is provided. The leg-joint module 9 includes a knee joint motor module 11, a leg-joint housing 12 and The leg-joint cover plate 13; the leg-joint cover plate 13 is mounted on the leg-joint shell 12, and the leg-joint cover plate 13 and the leg-joint shell 12 are provided with an 'L' shaped cavity The knee joint motor module 11 is fixedly installed at one end of the 'L'-shaped cavity, and the side wall of the other end of the 'L'-shaped cavity is fixedly installed on the top output end of the hip joint motor module 7 . The knee joint motor module 11 is an integrated motor module, which is integrally connected by a reducer, a motor and a driver. Other structural connections are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com