Top temperature control method for vertical co-firing lime kiln

A control method and lime kiln technology are applied in the field of top temperature control of a vertical mixed-burning lime kiln, which can solve the problems of insufficient consideration of the influence of air intake, unstable control effect, fluctuation of production load, etc., so as to improve the accuracy and Timeliness, optimized control, stable effect of calcination zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

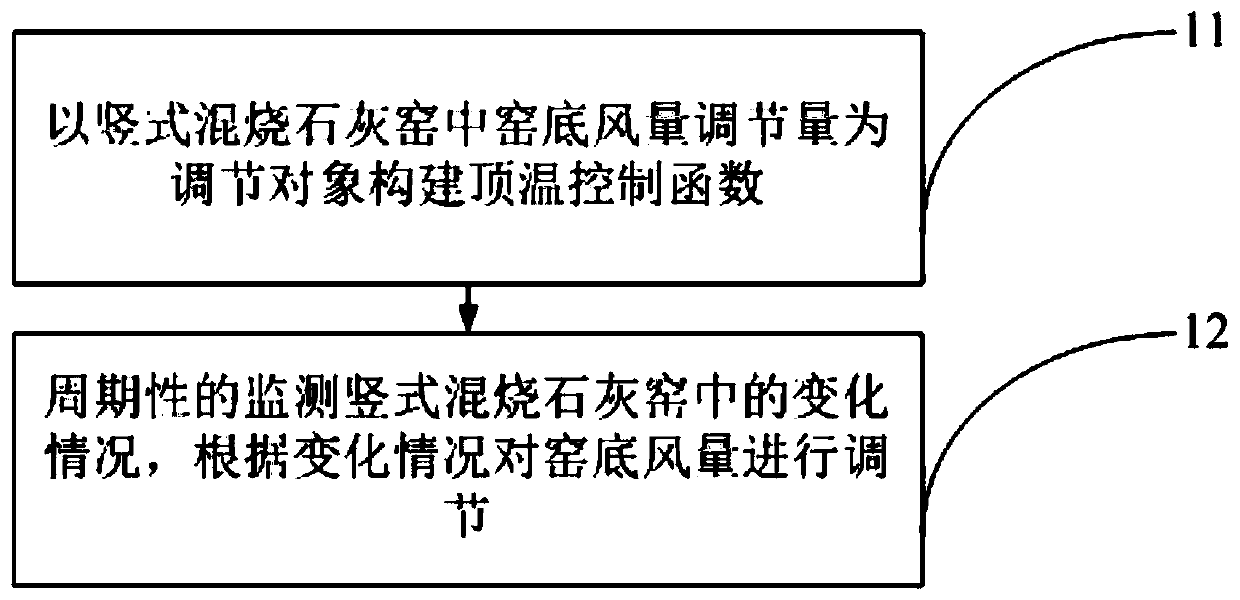

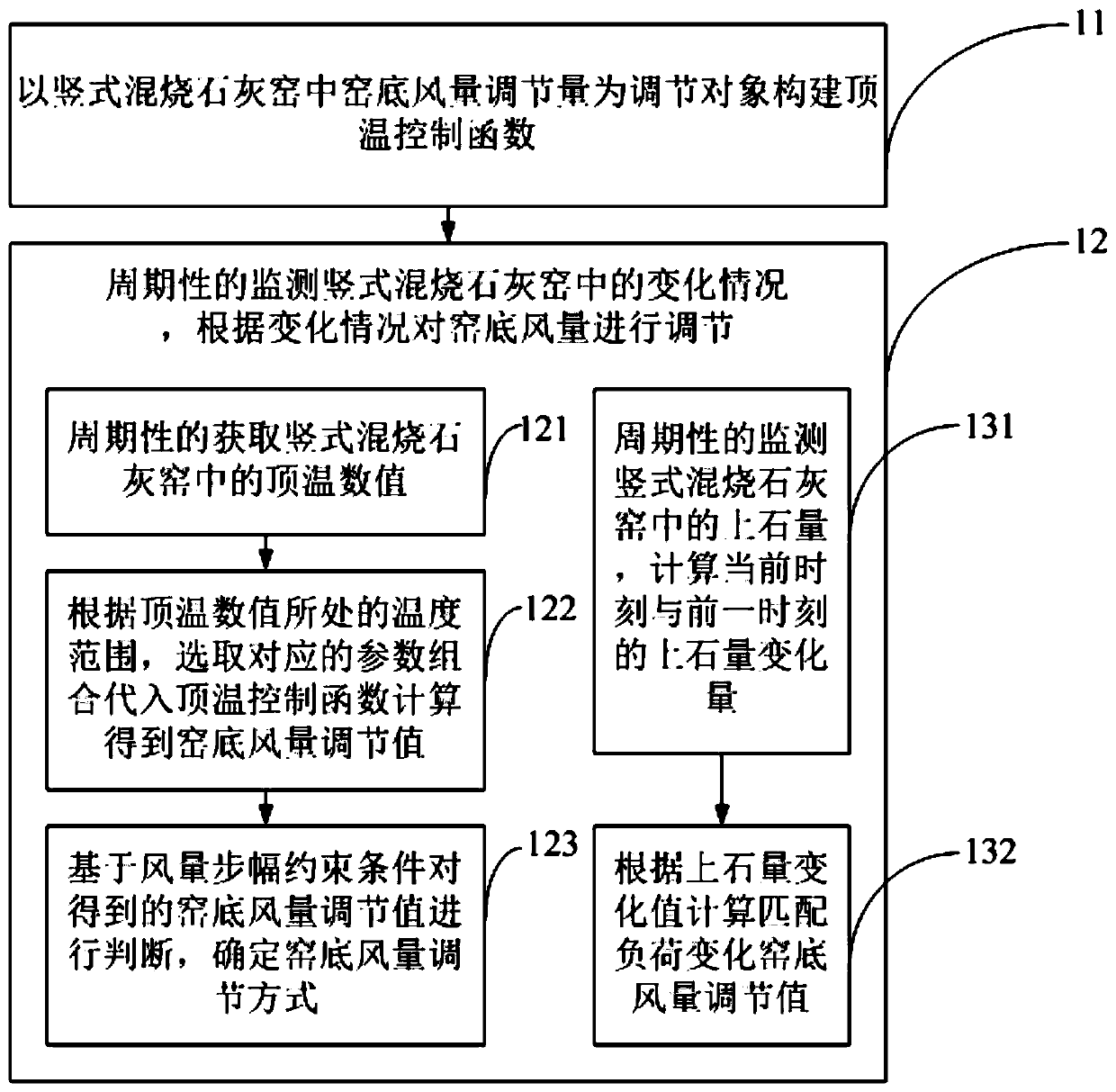

[0065] Specifically, the embodiment of this application proposes a top temperature control method for a vertical mixed-fired lime kiln, such as figure 1 shown, including:

[0066] 11. Construct the top temperature control function with the kiln bottom air volume adjustment in the vertical mixed-fired lime kiln as the adjustment object;

[0067] 12. Periodically monitor the change of top temperature in the vertical mixed-fired lime kiln, and adjust the air volume at the bottom of the kiln according to the historical value of the top temperature combined with the constraints of the air volume step.

[0068] In practice, the present invention is mainly used for the top temperature control of the vertical mixed-fired lime kiln in the industrial production process. According to the production process data such as the lime kiln top temperature, material loading (limestone), and kiln bottom air intake, combined with the kiln working conditions, the lime kiln top temperature is finel...

Embodiment 2

[0125] In the first embodiment, the control method for calculating the air intake at the bottom of the kiln based on the change of the top temperature is given to realize the control of the top temperature. The air intake is calculated in order to realize the control method of top temperature control.

[0126] Specifically include:

[0127] 131. Periodically monitor the amount of stone loaded in the vertical mixed-fired lime kiln, and calculate the change in the amount of stone loaded at the current moment and the previous moment;

[0128] 132. Calculate the adjustment value of the kiln bottom air volume matching the load change according to the change value of the stone loading amount.

[0129] Wherein, the adjustment value of air volume at the bottom of the kiln according to the change value of the stone loading amount proposed in step 132 is calculated to match the load change, including:

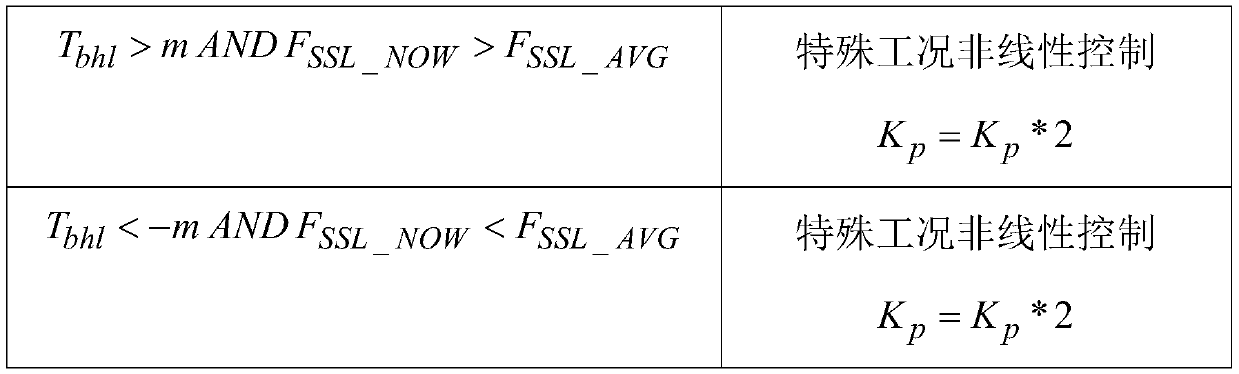

[0130] The control method proposed in this example is based on the adjustment meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com