Rubber ball cleaning device capable of automatically replacing rubber balls

A technology for automatic replacement and cleaning of devices. It is used in cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment. High efficiency and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

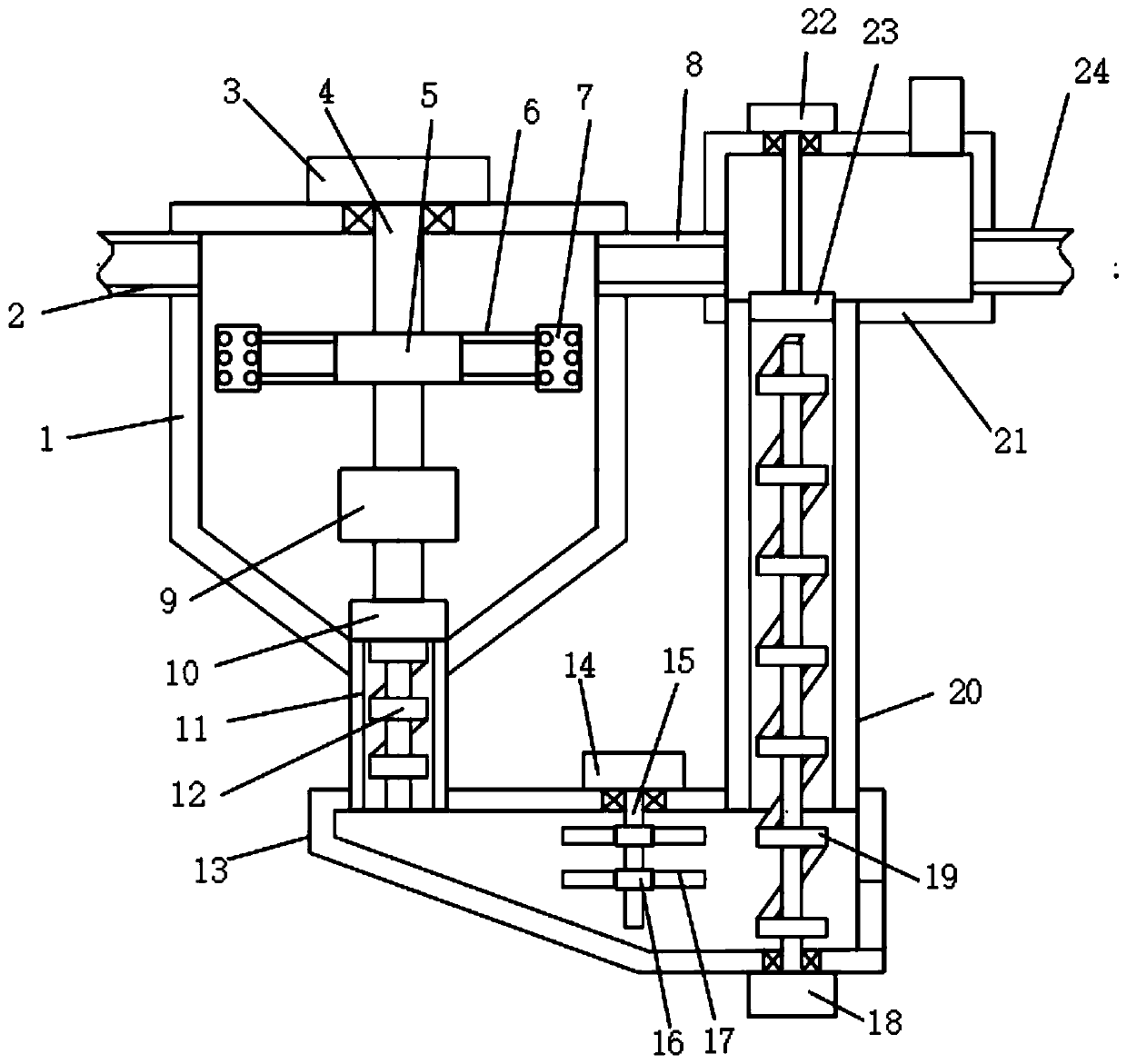

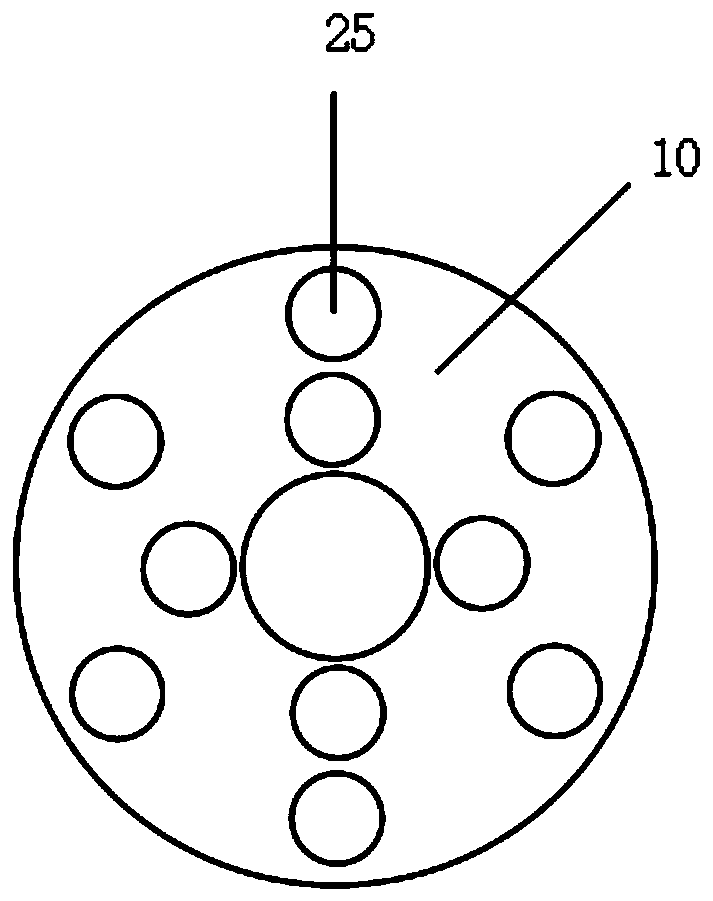

[0025] refer to Figure 1-2 , a rubber ball cleaning device that can automatically replace rubber balls, including a first housing 1, a first connecting pipe 8 runs through the side of the first housing 1, and a third housing 21 is fixed on the side of the first connecting pipe 8 , the bottom of the first housing 1 is provided with a second connecting pipe 11, the bottom of the second connecting pipe 11 is fixed with a second housing 13, and the top of the second housing 13 is fixed with a third Connecting pipe 20, the top of the third connecting pipe 20 is fixedly connected with the third housing 21, the top of the first housing 1 is equipped with the first motor 3, the output shaft of the first motor 3 is inserted into the inside of the first housing 1 and Connected with a reciprocating screw rod 4, the reciprocating screw rod 4 is connected with a threaded sleeve 5 through a thread sleeve, the side of the threaded sleeve 5 is welded with a bracket 6, and the end of the brac...

Embodiment 2

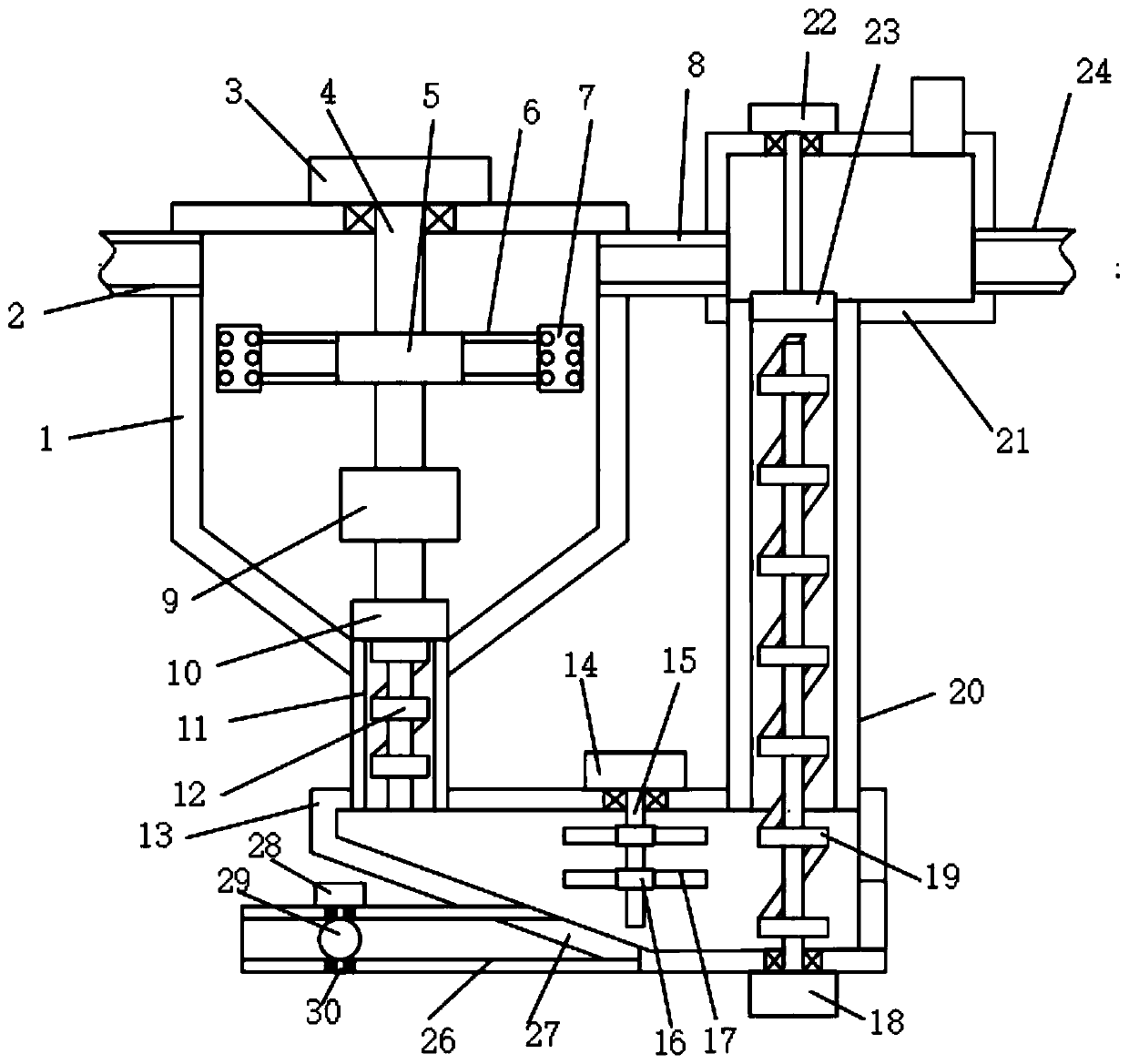

[0034] refer to Figure 2-4, a rubber ball cleaning device that can automatically replace rubber balls, including a first housing 1, a first connecting pipe 8 runs through the side of the first housing 1, and a third housing 21 is fixed on the side of the first connecting pipe 8 , the bottom of the first housing 1 is provided with a second connecting pipe 11, the bottom of the second connecting pipe 11 is fixed with a second housing 13, and the top of the second housing 13 is fixed with a third Connecting pipe 20, the top of the third connecting pipe 20 is fixedly connected with the third housing 21, the top of the first housing 1 is equipped with the first motor 3, the output shaft of the first motor 3 is inserted into the inside of the first housing 1 and Connected with a reciprocating screw rod 4, the reciprocating screw rod 4 is connected with a threaded sleeve 5 through a thread sleeve, the side of the threaded sleeve 5 is welded with a bracket 6, and the end of the brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com