Test board for frequency converter production and using method of test board

A frequency converter and test bench technology, which is applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems such as prone to missing inspections, high labor intensity, and complex functions of frequency converters, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

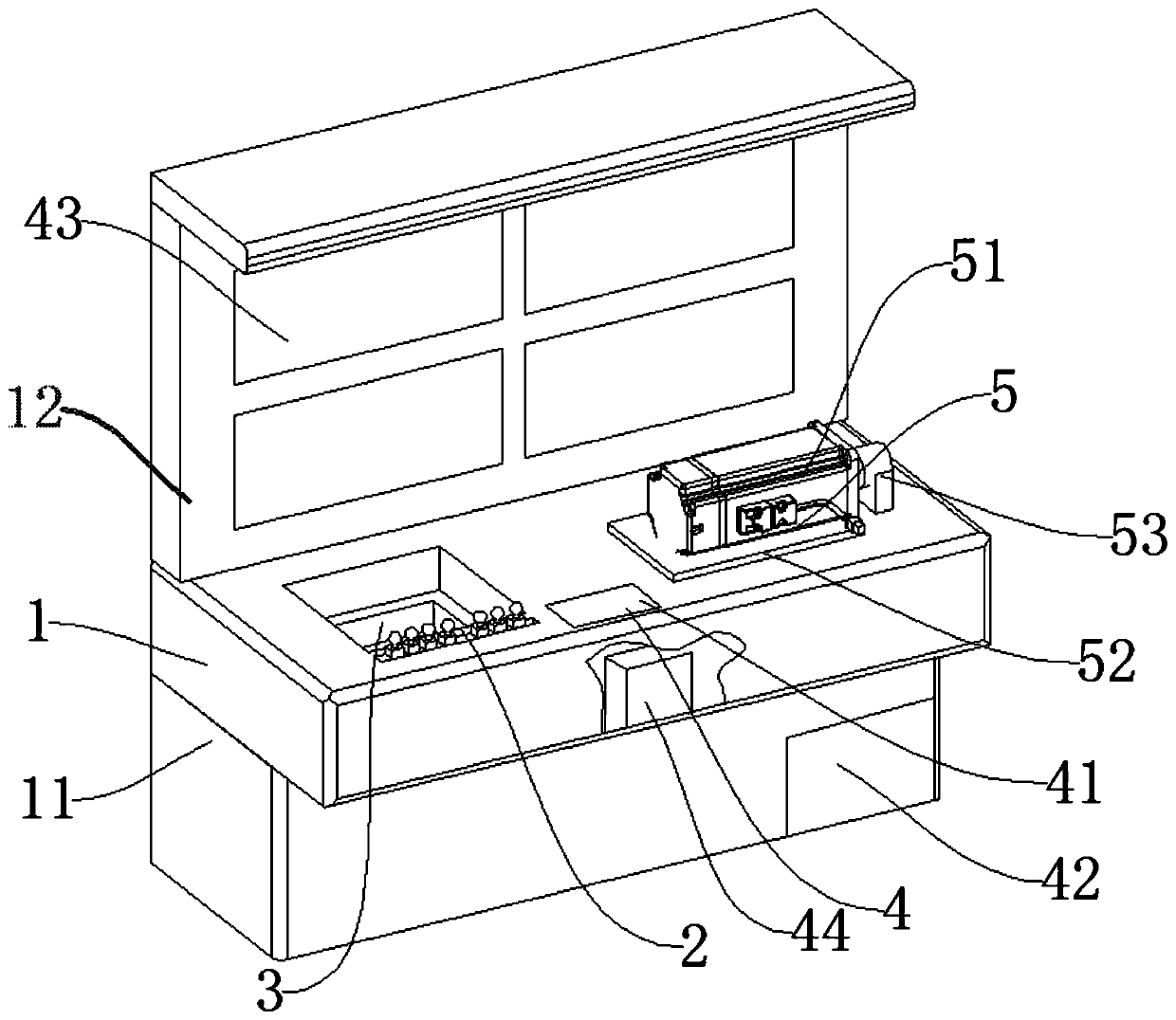

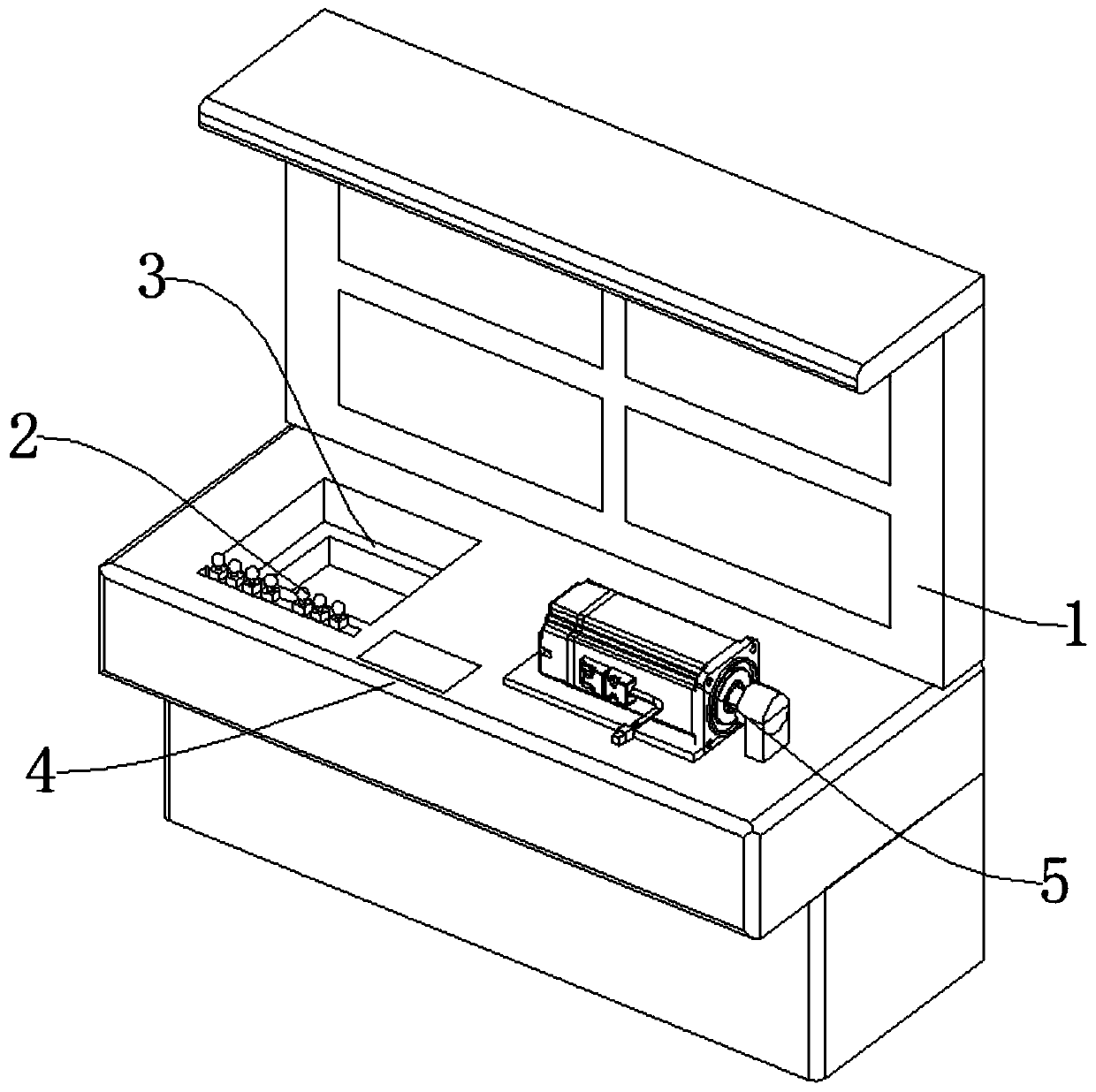

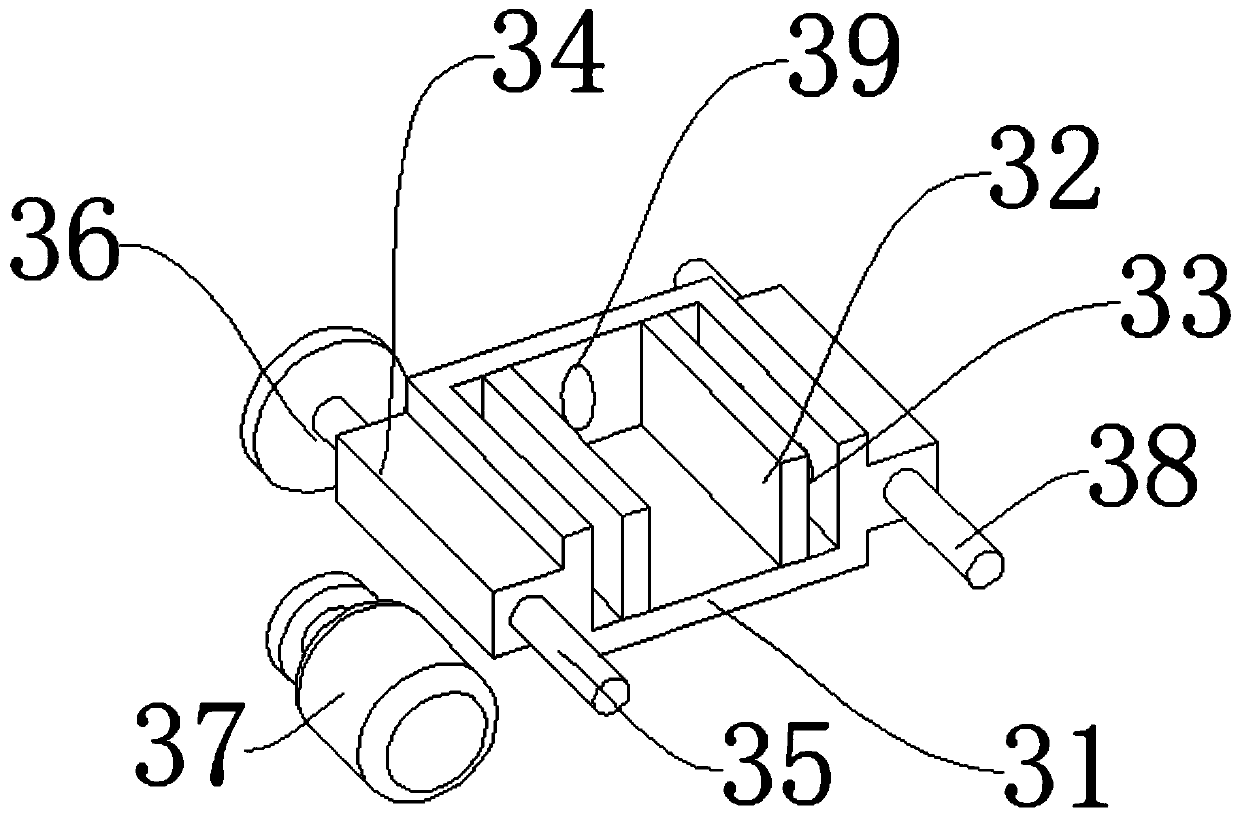

[0042] Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 6As shown, the fixing mechanism 3 includes a first fixing seat 31, a side splint 32, a clamping cylinder 33, and a slider 34. The first fixing seat 31 is slidably connected to the base 11 of the support mechanism 1, and the side splint 32 is arranged on the first fixing Inside the seat 31, a clamping cylinder 33 is arranged between the first fixed seat 31 and the side splint 32, the two ends of the first fixed seat 31 are connected to the slider 34 by welding, and the slider 34 at one end is threaded to connect the screw rod 35, the screw rod 35 The rear end is connected to the gear set 36, the gear set 36 is connected to the motor 37, the slider 34 at the other end is connected to the slide rod 38, the slide rod 38 is connected to the support mechanism 1, the pressure sensor 39 is connected to the inner rear end of the first fixed seat 31, and the screw rod 35 is linked Function, the stability during mov...

Embodiment 2

[0044] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the fixing mechanism 3 includes a second fixing seat 311, a side splint 32, a clamping cylinder 33, and a slider 34, and the inside of the second fixing seat 311 is provided with a side splint 32 , a clamping cylinder 33 is arranged between the second fixed seat 311 and the side splint 32 , sliders 34 are arranged at both ends of the second fixed seat 311 , a slide bar 38 is arranged on the slider 34 , and the rear side of the second fixed seat 311 A push head 313 is provided, the front end of the push head 313 is provided with a pressure sensor 39, the rear end of the push head 313 is provided with a telescopic cylinder 312, the telescopic cylinder 312 acts as an energy supply, and the push head 313 acts as a drive for a frequency converter.

[0045] A method for using a test bench for frequency converter production, comprising ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com