A general approach for tool wear prediction and machining parameter optimization for flat-nosed micro-milling

A technology of machining parameters and tool wear, applied in general control systems, instruments, computer control, etc., can solve problems such as the lack of universal wear prediction models/methods, the difficulty of observing the wear state of micro-milling tools, and the lack of optimization models for machining parameters. , to avoid inaccurate prediction, improve processing efficiency, and prolong tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

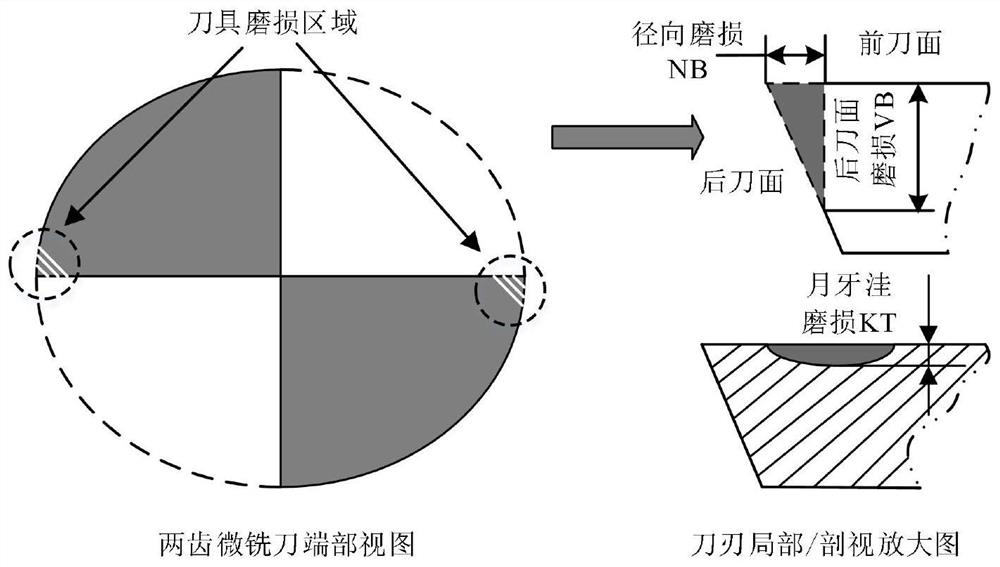

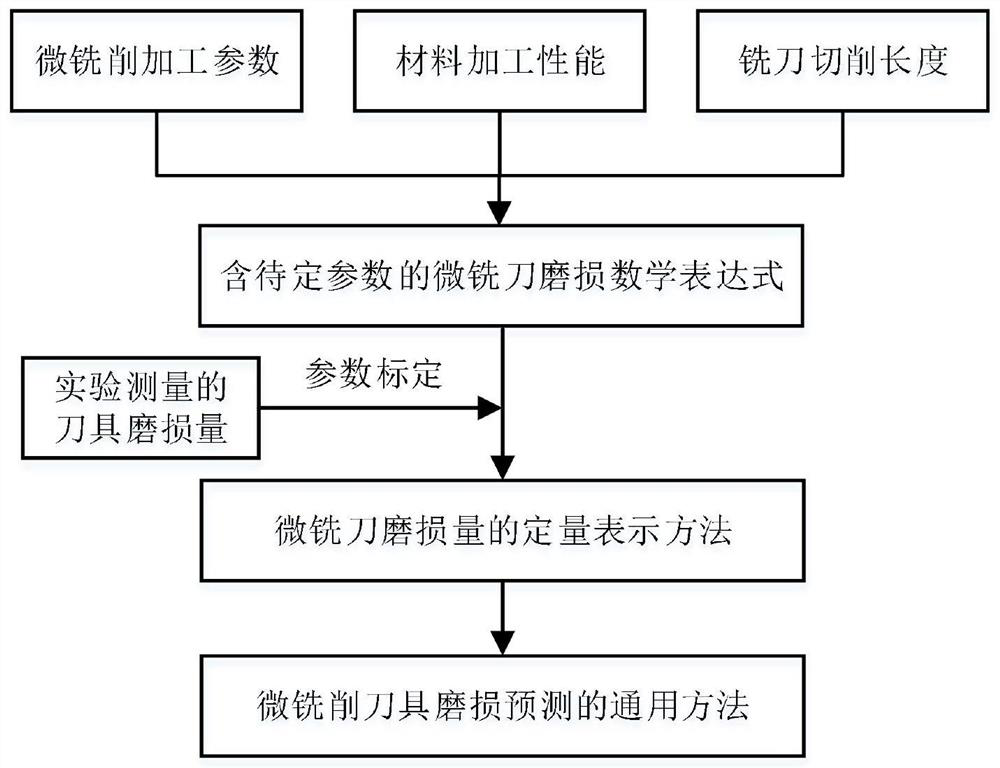

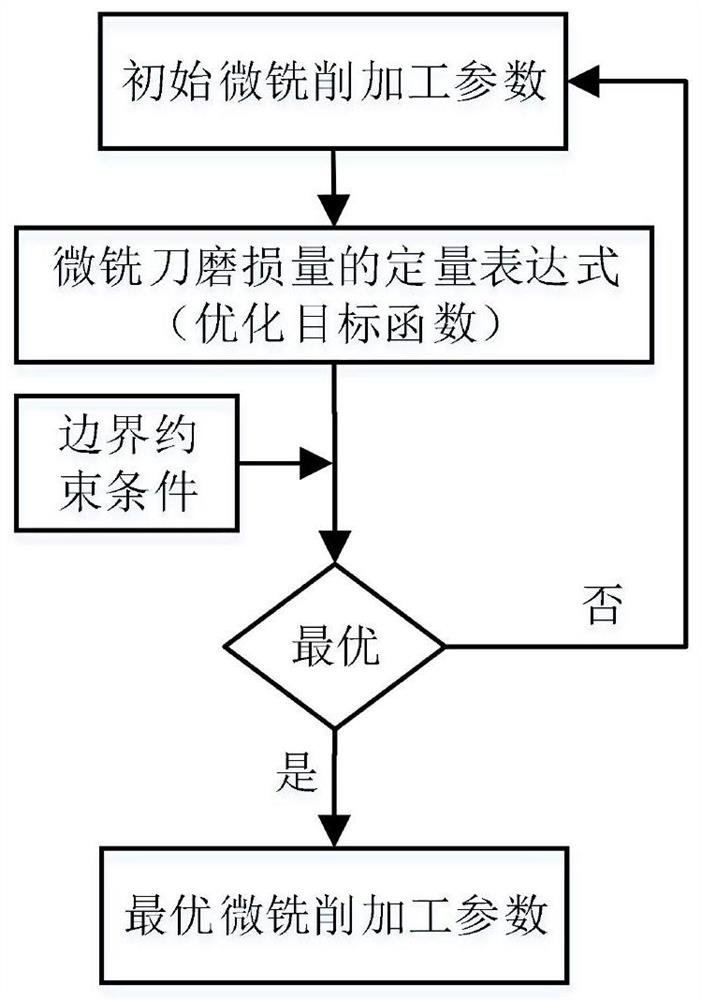

[0036]In this embodiment, a general method for wear prediction and processing parameter optimization of flat-end micro-milling tools is to use a combination of theory and experiments to determine the wear amount of micro-milling tools and processing parameters, milling cutter The quantitative relationship between cutting length and material processing performance realizes the prediction of micro-milling tool wear and the optimization of processing parameters. Firstly, according to the micro-milling processing parameters, material processing performance and milling cutter cutting length, a tool wear model including unknown parameters is established; secondly, according to the micro-milling cutter wear data obtained from the experiment, the parameters in the tool wear model are calibrated by numerical method; finally , using the micro-milling tool wear model, not only can predict the tool wear state, judge the remaining service life, but also optimize the milling parameters, thus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com