A sintering process for the preparation of positive electrode materials for lithium-ion batteries

A cathode material and lithium ion technology, which is applied in the field of preparation of cathode materials for lithium ion batteries, can solve the problems of low energy conversion utilization rate, material stuck in the furnace, slow sintering speed, etc., and achieves high energy utilization rate and material transport. The effect of less transportation process and uniform reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

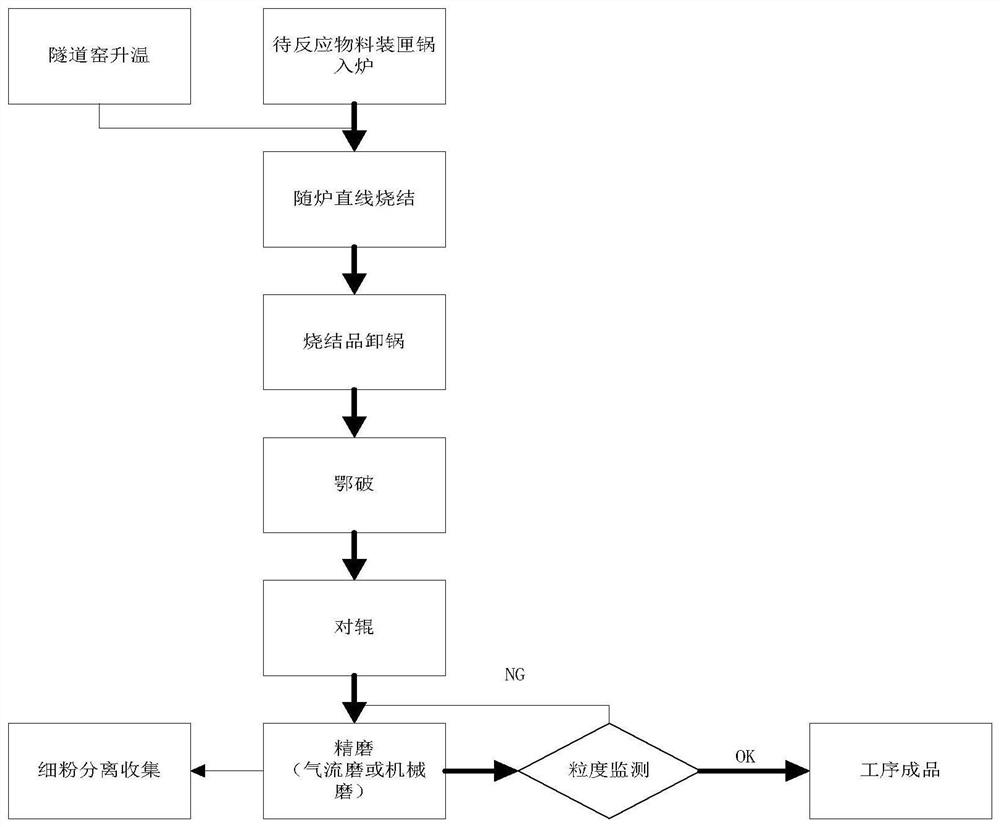

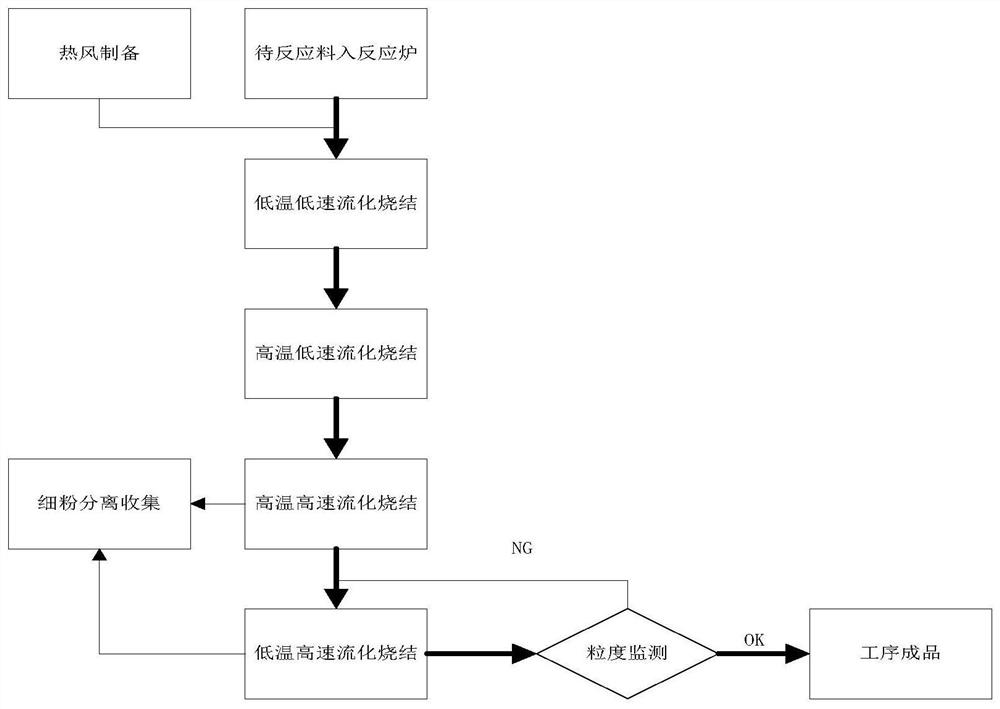

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Wherein, the high-temperature clean hot air source for the material reaction and fluidization is air.

[0030] Wherein, in the first step of low-temperature and low-speed fluidization sintering, the hot air temperature is 400° C., the wind speed is 75 m / s, and the sintering fluidization time is 2 hours. In the second step of high-temperature and low-speed fluidization sintering, the hot air temperature is 700° C., the wind speed is 225 m / s, and the sintering fluidization time is 2 hours. In the third step of high-temperature and high-speed fluidized sintering, the hot air temperature is 980° C., the wind speed is 350 m / s, and the sintering fluidization time is 4 hours. In the fourth step of low temperature and high speed fluidization sintering, the hot air temperature is 150°C, the wind speed is 350m / s, and the sintering fluidization time is 1h.

Embodiment 2

[0031] Embodiment 2: Wherein, the high-temperature clean hot air source for the material reaction and fluidization is air.

[0032] Wherein, in the first step of low-temperature and low-speed fluidization sintering, the hot air temperature is 500° C., the wind speed is 75 m / s, and the sintering fluidization time is 2 hours. In the second step of high-temperature and low-speed fluidized sintering, the hot air temperature is 800° C., the wind speed is 225 m / s, and the sintering fluidization time is 2 hours. In the third step of high-temperature and high-speed fluidized sintering, the hot air temperature is 1020° C., the wind speed is 350 m / s, and the sintering fluidization time is 4 hours. In the fourth step of low temperature and high speed fluidization sintering, the hot air temperature is 180°C, the wind speed is 350m / s, and the sintering fluidization time is 1h.

Embodiment 3

[0033] Embodiment 3: Wherein, the high-temperature clean hot air source for the material reaction and fluidization is air.

[0034] Wherein, in the first step of low-temperature and low-speed fluidization sintering, the hot air temperature is 600° C., the wind speed is 75 m / s, and the sintering fluidization time is 2 hours. In the second step of high-temperature and low-speed fluidization sintering, the hot air temperature is 900° C., the wind speed is 225 m / s, and the sintering fluidization time is 2 hours. In the third step of high-temperature and high-speed fluidized sintering, the hot air temperature is 1100° C., the wind speed is 350 m / s, and the sintering fluidization time is 4 hours. In the fourth step of low-temperature and high-speed fluidization sintering, the hot air temperature is 200° C., the wind speed is 350 m / s, and the sintering fluidization time is 1 h.

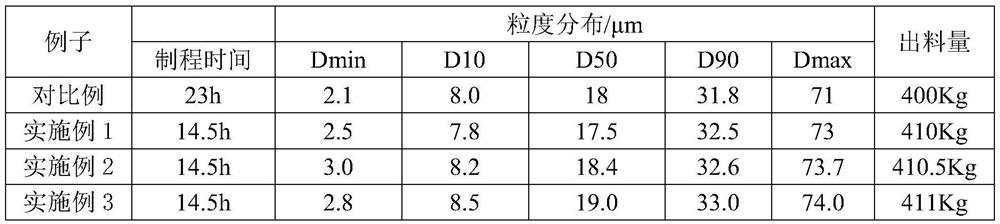

[0035] The above comparative examples are compared with the parameters of the finished products of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com