Lithium ion battery copper/aluminum foil coating water-based conductive paste and preparation method thereof

A technology of lithium-ion batteries and conductive pastes, applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of battery overall performance degradation, reduction of electron conduction paths, and slow peeling, etc., to improve the surface Effects of tension, enhancement of coating properties, and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

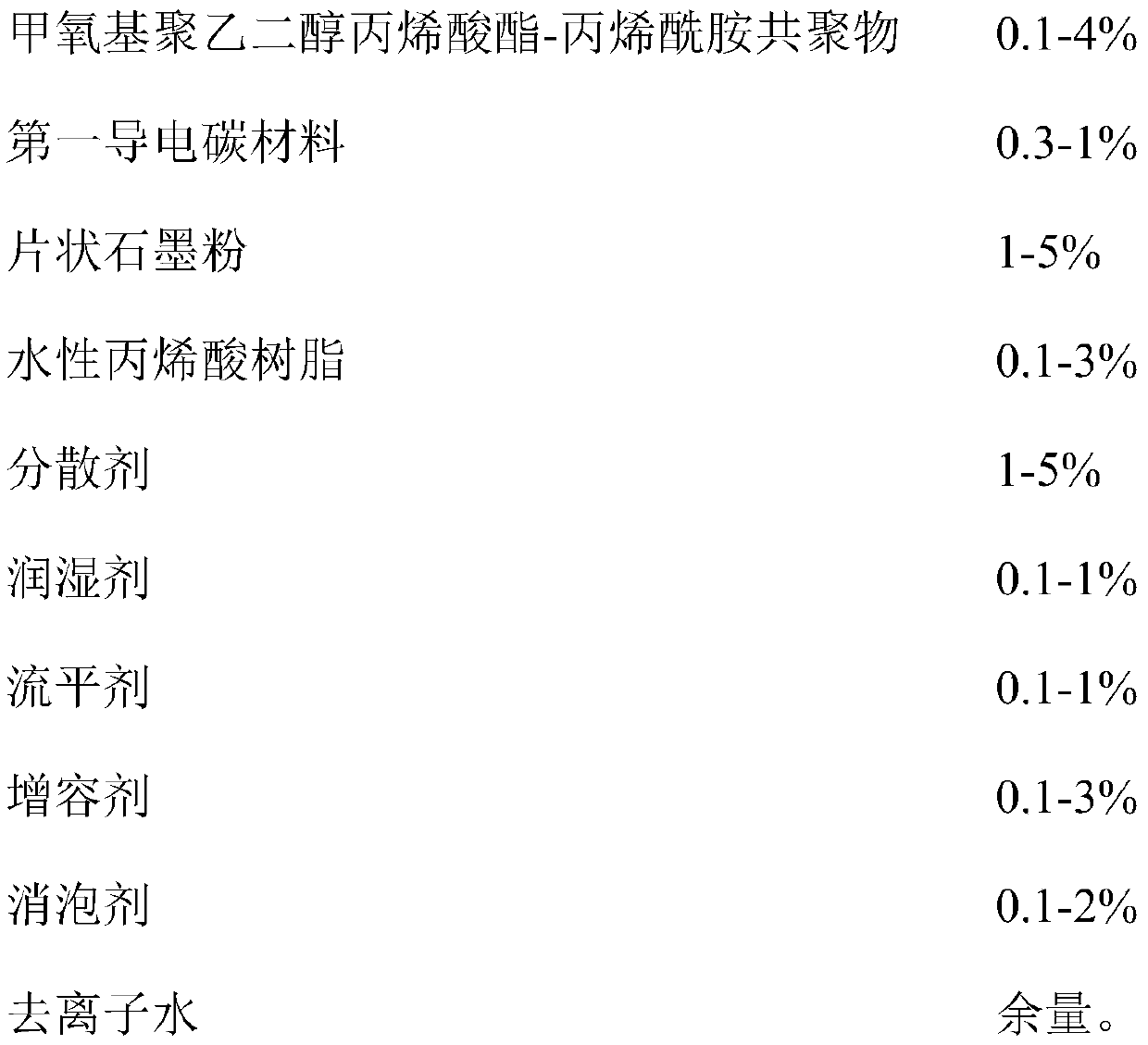

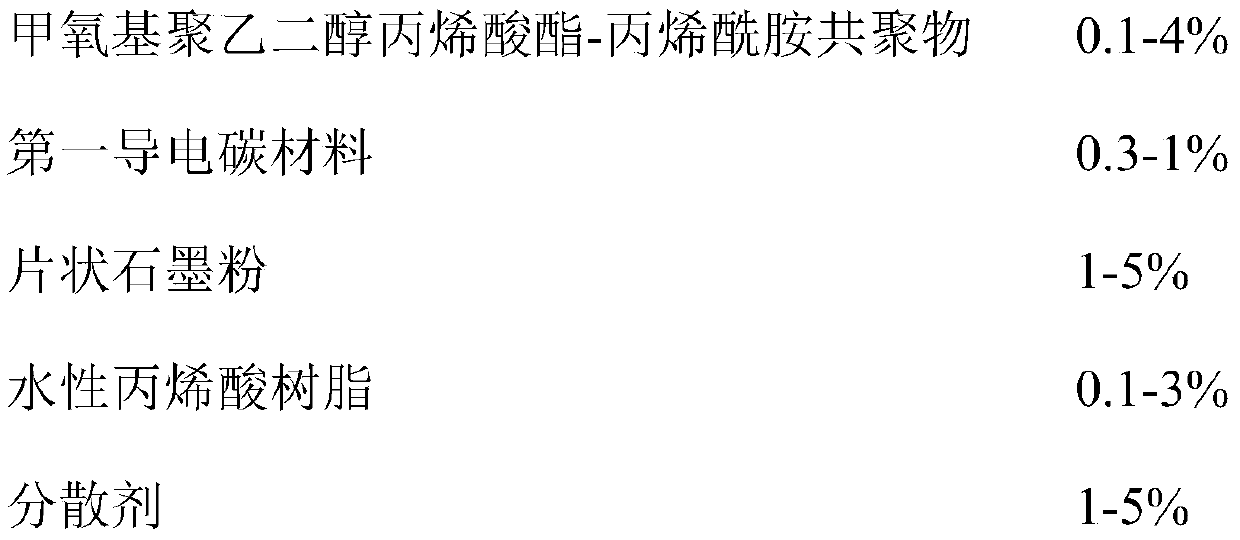

[0024] A kind of lithium ion battery copper / aluminum foil is coated with aqueous conductive paste, comprises following component by mass fraction,

[0025]

[0026]

[0027] The specific preparation method is: mix and dissolve methoxy polyethylene glycol acrylate-acrylamide copolymer, acetylacetone, wetting agent and water according to the proportion; add carbon nanotubes and flake graphite powder and stir evenly, and obtain Conductive paste pre-dispersion; the conductive paste pre-dispersion is ground and dispersed to obtain a conductive paste dispersion. When using a sand mill to process the conductive paste pre-dispersion, the fineness is controlled to be less than 2 microns, and the grinding is performed 10 times; The slurry dispersion is mixed with water-based acrylic resin, leveling agent, polyvinyl alcohol, and modified silicone defoamer at high speed to obtain the final conductive paste.

Embodiment 2

[0029] A kind of lithium ion battery copper / aluminum foil is coated with aqueous conductive paste, comprises following component by mass fraction,

[0030]

[0031]

[0032] The specific preparation method is: mix and dissolve methoxypolyethylene glycol acrylate-acrylamide copolymer, ethylenediaminetetraacetic acid, wetting agent and water according to the proportion; add graphene and flake graphite powder and stir evenly, Grinding to obtain a conductive paste pre-dispersion; the conductive paste pre-dispersion is ground and dispersed to obtain a conductive paste dispersion. When using a sand mill to process the conductive paste pre-dispersion, the fineness is controlled to be less than 2 microns, and the grinding is performed 15 times ; The conductive paste dispersion is mixed with water-based acrylic resin, leveling agent, polyvinyl alcohol, and polyether defoamer at high speed to obtain the final conductive paste.

Embodiment 3

[0034] A kind of lithium ion battery copper / aluminum foil is coated with aqueous conductive paste, comprises following component by mass fraction,

[0035]

[0036]

[0037] The specific preparation method is: mix and dissolve methoxy polyethylene glycol acrylate-acrylamide copolymer, ethylenediamine tetraacetic acid, wetting agent and water according to the proportion; add conductive carbon black and flake graphite powder and stir evenly, The colloid mill obtains the pre-dispersion of conductive paste; the pre-dispersion of conductive paste is ground and dispersed to obtain the dispersion of conductive paste. The conductive paste dispersion is mixed with water-based acrylic resin, leveling agent, cellulose nanospheres, and polysiloxane defoamer at high speed to obtain the final conductive paste.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap