Dual frequency fss with closely spaced frequency response characteristics and its unit structure

A technology of interval frequency and response characteristics, applied in the field of dual-frequency FSS and its unit structure, can solve the problems of large size, large resonance response interval, unable to meet the requirements of FSS, etc., and achieve good angular stability and good polarization stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

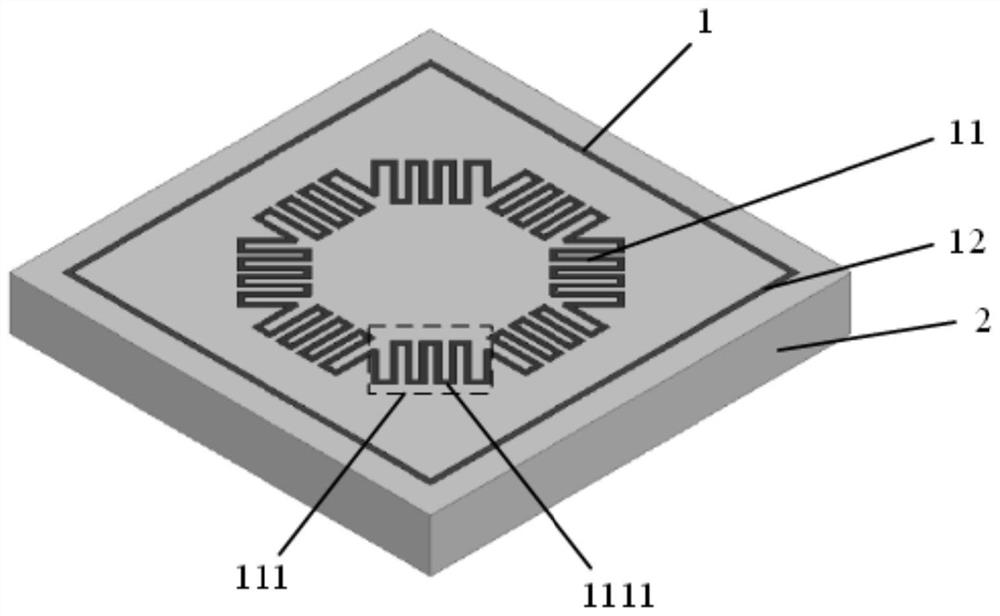

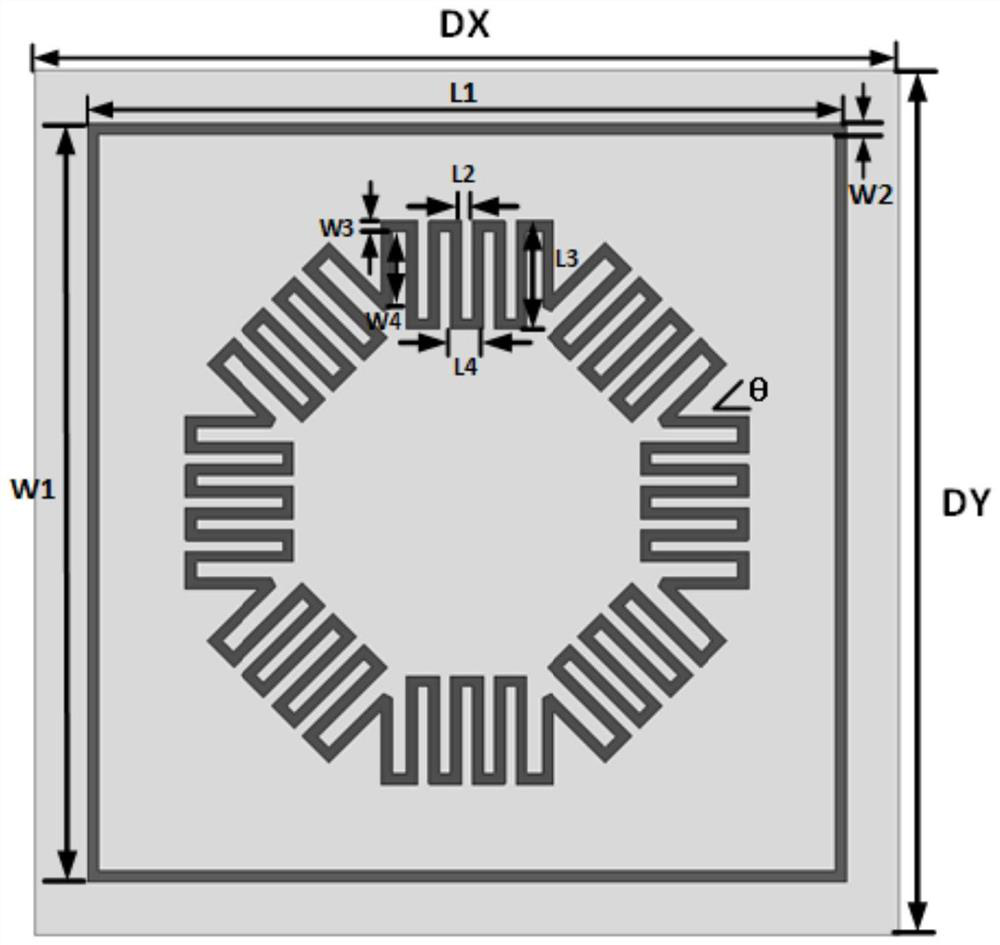

[0038] See figure 1 and figure 2 , figure 1 It is a perspective view of a dual-frequency FFS unit structure with closely spaced frequency response characteristics provided by an embodiment of the present invention; figure 2 It is a side view of a dual-frequency FFS unit structure with closely spaced frequency response characteristics provided by an embodiment of the present invention. The dual-frequency FFS unit structure includes a metal layer 1 and a dielectric substrate 2 , and the metal layer 1 is disposed on the dielectric substrate 2 . In this embodiment, the upper surface of the dielectric substrate 2 has a square structure with a size of 8mm*8mm. In addition, the thickness of the metal layer 1 is in the range of 0.017mm-0.035mm, and the thickness of the dielectric substrate 2 is 1mm. Compared with the existing FFS unit, the size of the dual-frequency FFS unit structure in this embodiment is very small, meeting the current trend of pursuing miniaturization of devi...

Embodiment 2

[0047] On the basis of the above embodiments, this embodiment provides a dual-frequency FFS with closely spaced frequency response characteristics. See Figure 4 , Figure 4 It is a perspective view of a dual-frequency FFS with closely spaced frequency response characteristics provided by an embodiment of the present invention. The dual-frequency FFS includes M×N periodically arranged dual-frequency FFS unit structures as described in Embodiment 1, wherein M and N are integers greater than or equal to 1. In this embodiment, the dual-frequency FFS includes 6×6 unit structures. In other embodiments, the dual-frequency FFS may also include other numbers of unit structures, such as 10×10, 20×20, 40×40 ,even more.

[0048] As mentioned above, the dual-frequency FFS is formed by the periodic arrangement of the dual-frequency FFS unit structure described in the first embodiment, that is, the adjacent dielectric substrates 2 are closely attached. Since the distance between the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com