Rebound type injector with shielding needle eccentric blocking piece

A syringe and eccentric technology, applied in the field of syringes, can solve problems such as hidden safety hazards and re-extrusion of the casing, and achieve the effects of compact overall structure, simple self-destruction operation, and improved convenience and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

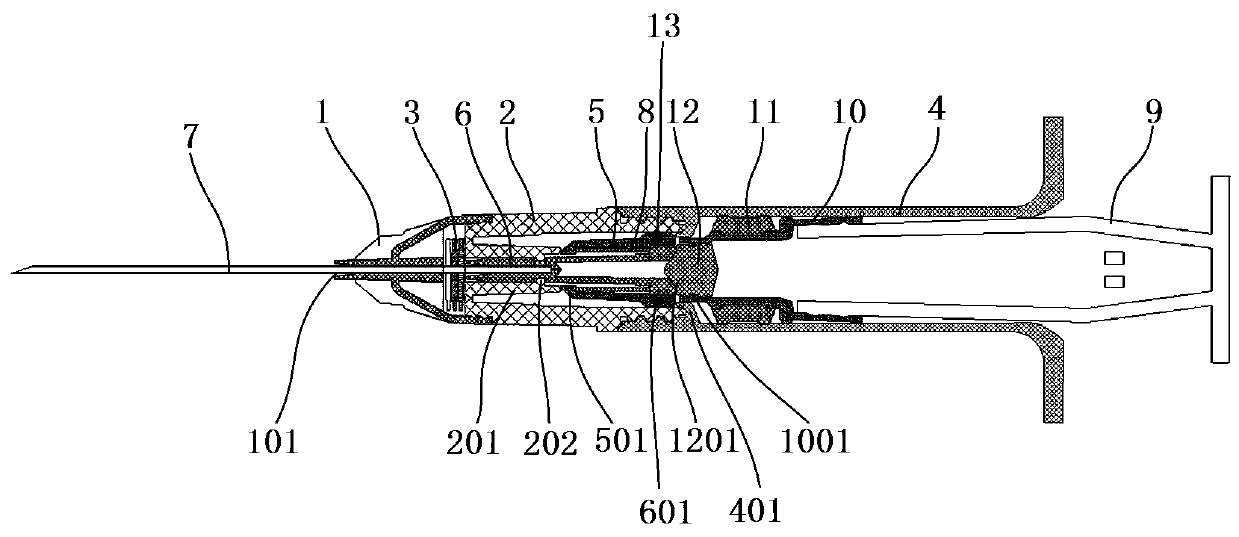

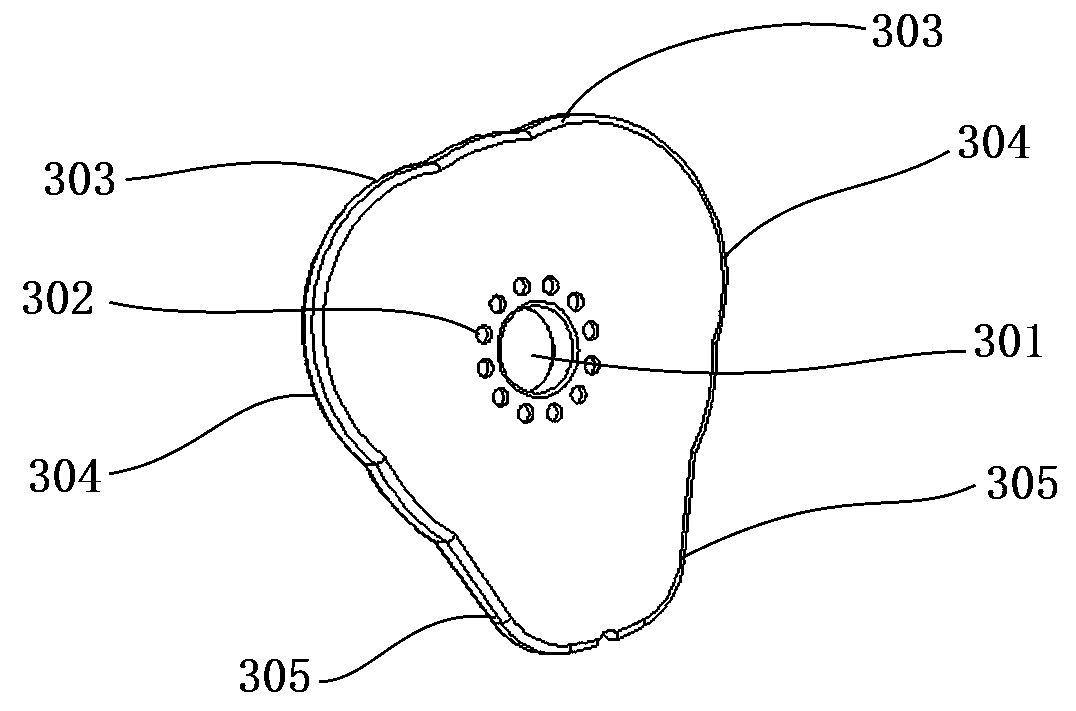

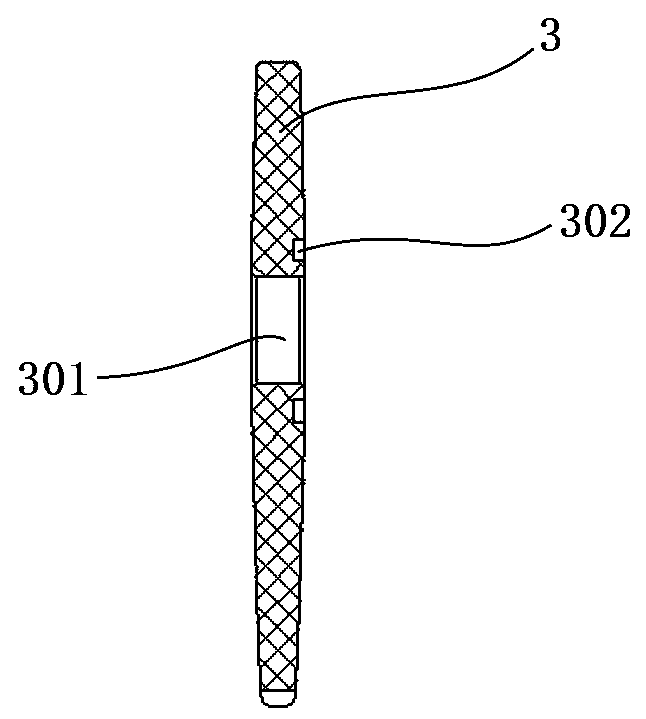

[0063] see figure 1 , a rebound type syringe with shielded needle eccentric block, including a protective cover 1, a large needle seat 2, an eccentric block 3, a syringe 4, a buffer bracket 5, a small needle seat 6, a needle tube 7, a spring 8, Core rod 9, core rod head 10, piston 11, buffer rubber plug 12, sealing ring 13.

[0064] A needle through hole 101 penetrating along the axis is opened in the protective cover 1 .

[0065] The front end of the large needle holder 2 is connected to the rear end of the protective cover 1, and the front part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com