Rice dust removal device

A dedusting device and rice technology, applied in grain processing, agriculture, application, etc., can solve the problems of rice nutrient loss and rice being easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

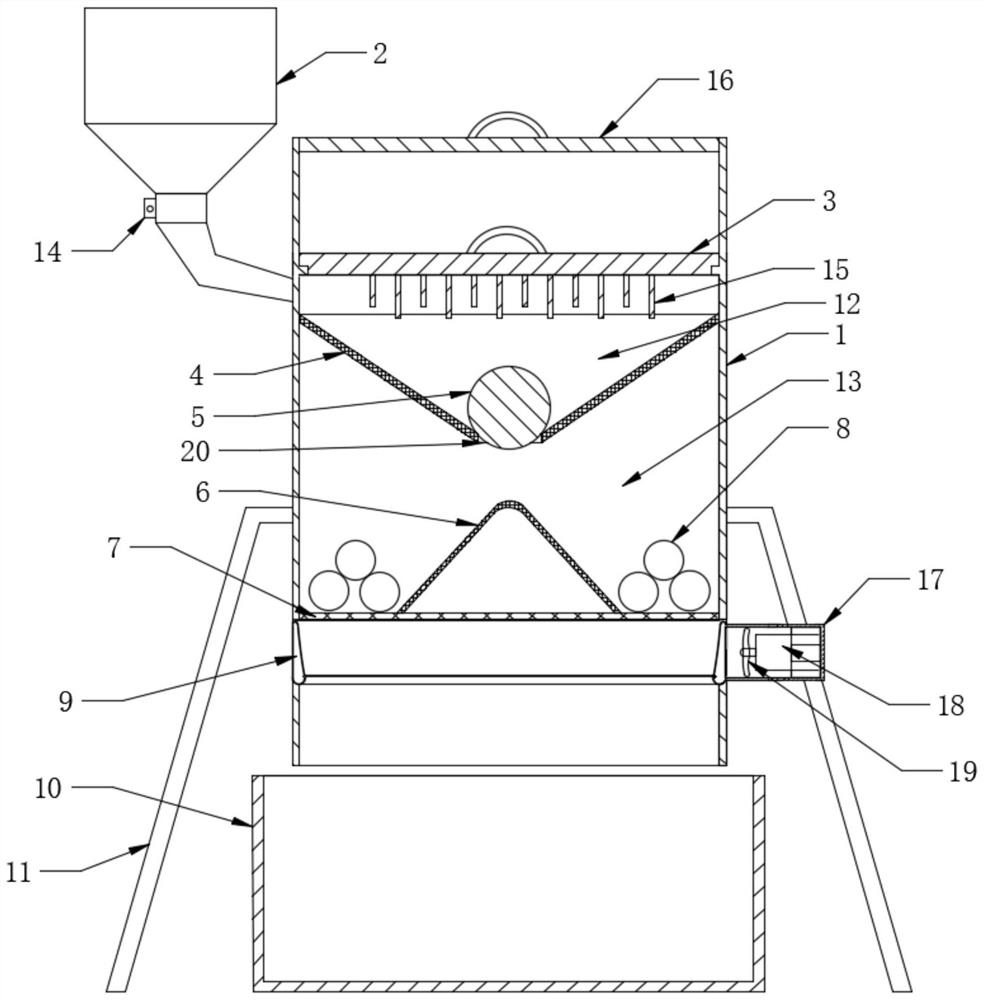

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

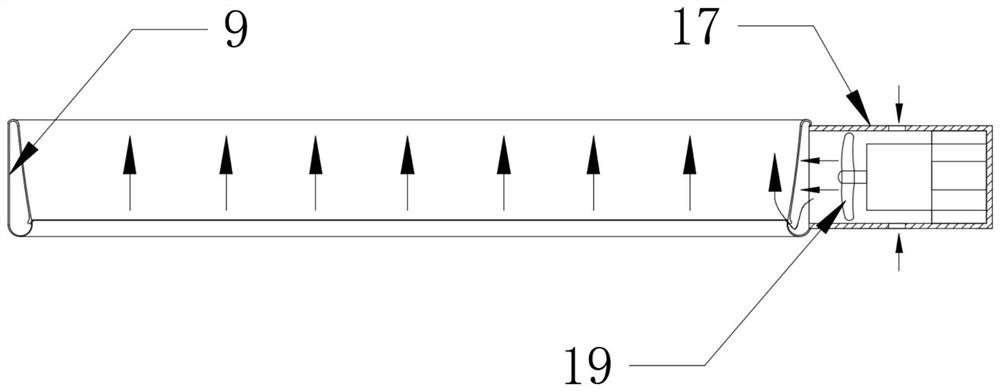

[0028] Such as Figure 1-7 The shown rice dedusting device includes an outer cylinder 1, a rice bin 2, a sponge cover 3, a net bag 4, a plug ball 5, a diversion net 6, a net plug 7, a sponge ball 8, an air ring 9, a rice box 10 and a frame 11 .

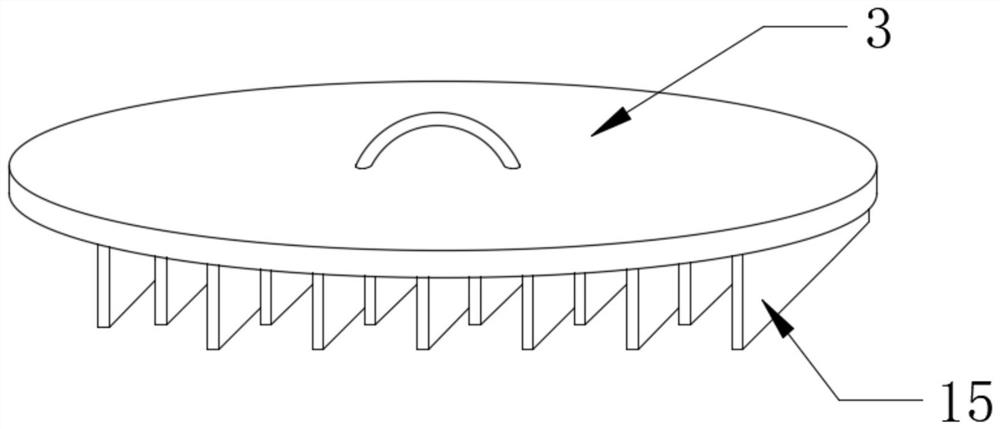

[0029] In this embodiment, the outer cylinder 1 is a cylindrical shape that penetrates up and down, and can also be other shapes that penetrate up and down; the sponge cover 3, the net pocket 4 and the net plug 7 are arranged in the outer cylinder 1 at intervals from top to bottom and the outer cylinder 1 The inner cavity is divided into a primary dust removal bin 12 and a secondary dust removal bin 13 from top to bottom.

[0030] The lower end surface of the sponge cover 3 is provided with a plurality of sponge strips 15; the lengths of the plurality of sponge strips 15 are staggered; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com