Material multi-stage sieve mixing, batch feeding integrated machine and mixing and feeding method

A material mixing and material technology, which is applied in mixers, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve the problems of poor cohesion, poor mixing uniformity, and long mixing time, and shorten the time. Mixing time, accelerated mixing rate, effect of accelerated mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

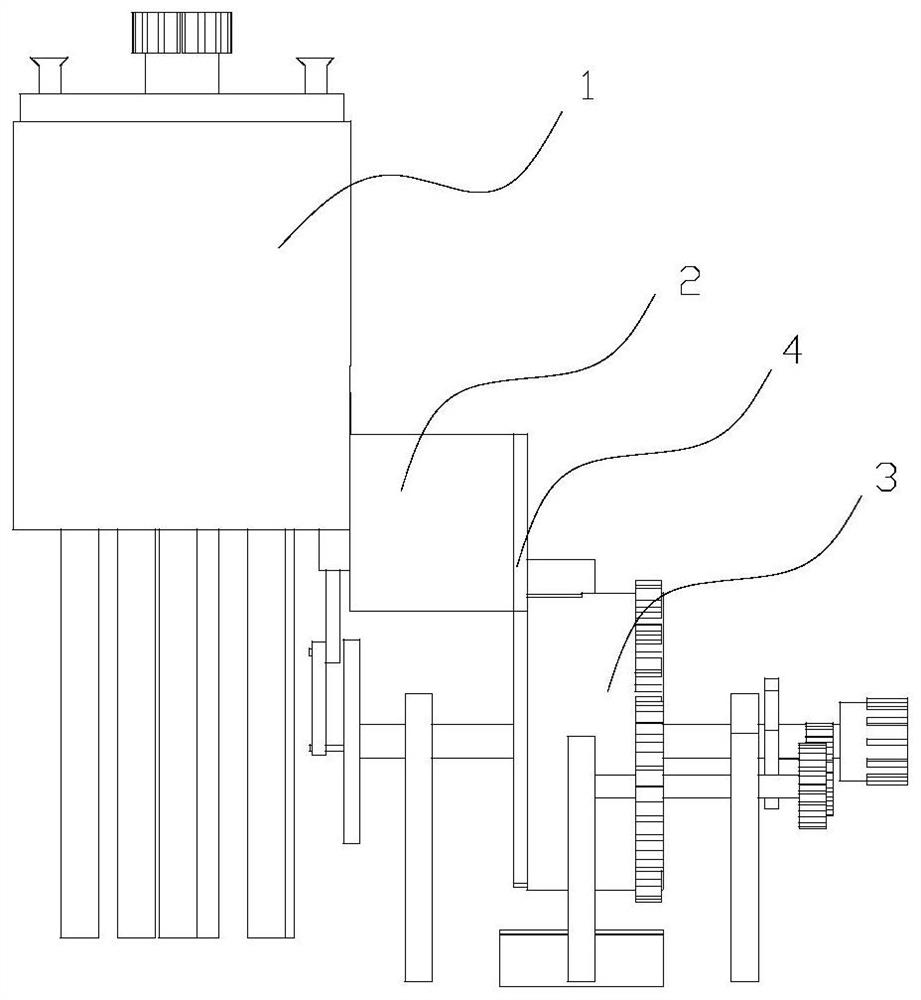

[0049] like Figure 1-3 As shown, this embodiment discloses an integrated machine for multi-stage sieving, mixing, and batch feeding of materials, including a material mixing tank 1 , a material guide channel 2 , a transfer material tray 3 , and a material blocking plate 4 . The lower end of the material mixing tank 1 is provided with a discharge port, and the gate 1135 is slidingly matched with the discharge port in the vertical direction to open and close the discharge port. A storage tank 31 is provided on the side opposite to the material mixing tank 1 in the transfer material tray 3 . The materials falling from the feeding port can be fed into the material storage tank 31 through the material guide channel 2 .

[0050] like Figure 4 As shown, the material mixing tank 1 of the present invention includes a material mixing tank shell, and a feeding port is opened below the material mixing tank shell, and the feeding port communicates with the inner cavity of the material ...

Embodiment 2

[0065] like figure 1 , 9 As shown, the difference between this embodiment and the above-mentioned embodiments is to provide a specific method for realizing the rotation of the mixing paddle 12 to drive multiple stirring paddles 1113 and multiple stirring bins 1111 to rotate synchronously, and the rotation direction of the stirring paddles 1113 is the same as that of the corresponding stirring bins. in the opposite direction of rotation.

[0066] A mixing paddle motor 13 is fixed on the top of the material mixing tank shell, the output shaft of the mixing paddle motor 13 is connected to the connecting end of the mixing paddle 12, and the mixing end of the mixing paddle 12 penetrates the material crushing chamber from top to bottom and extends into the material In the main mixing chamber 112. A first driving drive wheel 141 and a second driving drive wheel 142 are sheathed on a section of the material crushing chamber in the mixing paddle 12 .

[0067] There are two mixing ch...

Embodiment 3

[0073] like figure 1 , 9 As shown, the difference between this embodiment and the above-mentioned embodiment is to provide another specific method to realize that the rotation of the mixing paddle 12 drives a plurality of paddles 1113 and a plurality of agitation bins 1111 to rotate synchronously, and the rotation direction of the paddles 1113 is consistent with the corresponding stirring The direction of rotation of the bin is the opposite way.

[0074] A mixing paddle motor 13 is fixed on the top of the material mixing tank shell, the output shaft of the mixing paddle motor 13 is connected to the connecting end of the mixing paddle 12, and the mixing end of the mixing paddle 12 penetrates the material crushing chamber from top to bottom and extends into the material In the main mixing chamber 112. Two first driving wheels 141 and two second driving wheels 142 are sheathed on a section of the mixing paddle 12 located in the material crushing chamber. Two first driving tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com