Winnowing machine for separating cotton stalk fiber and floc

A floc and air separator technology, which is used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc. Excellent separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

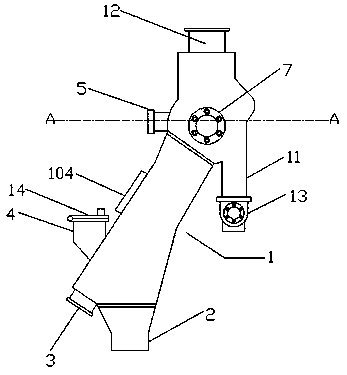

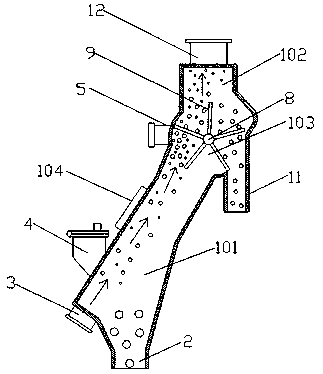

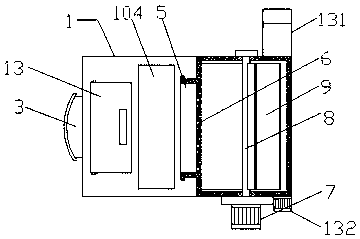

[0027]Embodiment 1 discloses a winnowing machine for separating cotton stalk fibers and flocs. The main structure includes an outer shell 1, and the outer shell includes a first winnowing bin 101 and a second winnowing bin 102. The first wind sorting bin is set at an inclination of 30~45° to the vertical direction, the bottom of the first sorting bin 101 is provided with an oversized material outlet 2, and the lower end of the first wind sorting bin 101 is provided with an air inlet 3. Its air inlet 3 is connected with an external blower (not shown in the figure), and provides strong wind force to the inside of the outer casing 1 to blow the cotton stalk fibers and flocs to the first winnowing bin 101. A feed hopper 4 is arranged on the inclined surface of the first air separation bin 101, a sealing cover 13 is rotated on the feed hopper 4, and a circular shunt bin 103 is arranged at the lower end of the second air separation bin 102. The lower end of the circular distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com